Tankless water heater

a tankless water heater and tank body technology, applied in the direction of heating types, domestic hot water supply systems, lighting and heating apparatus, etc., to achieve the effect of affecting the service life of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]To describe the technical contents, structural features and realization purposes and effects more clearly, the embodiments will be taken to detail the present invention in combination with the drawings.

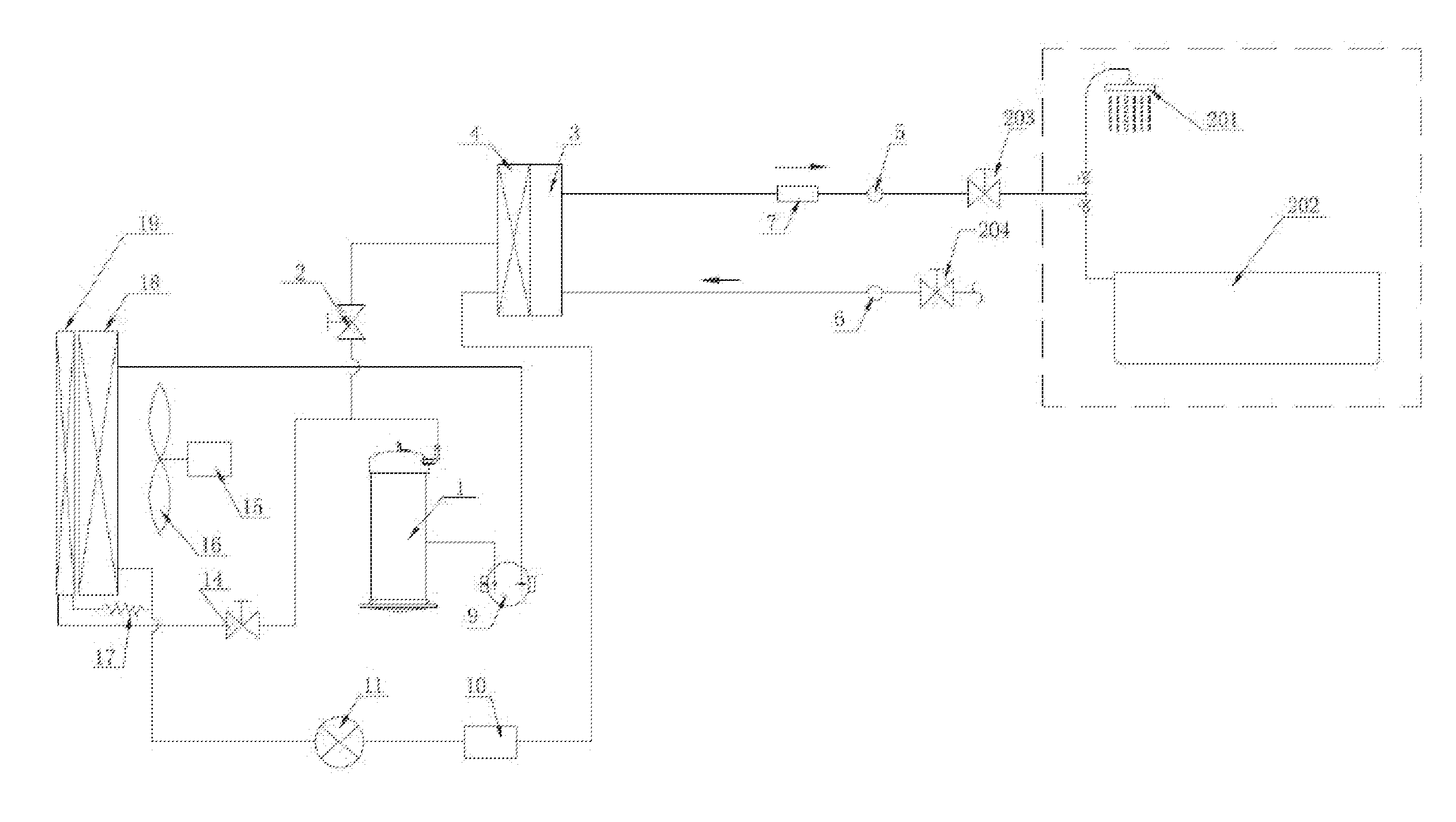

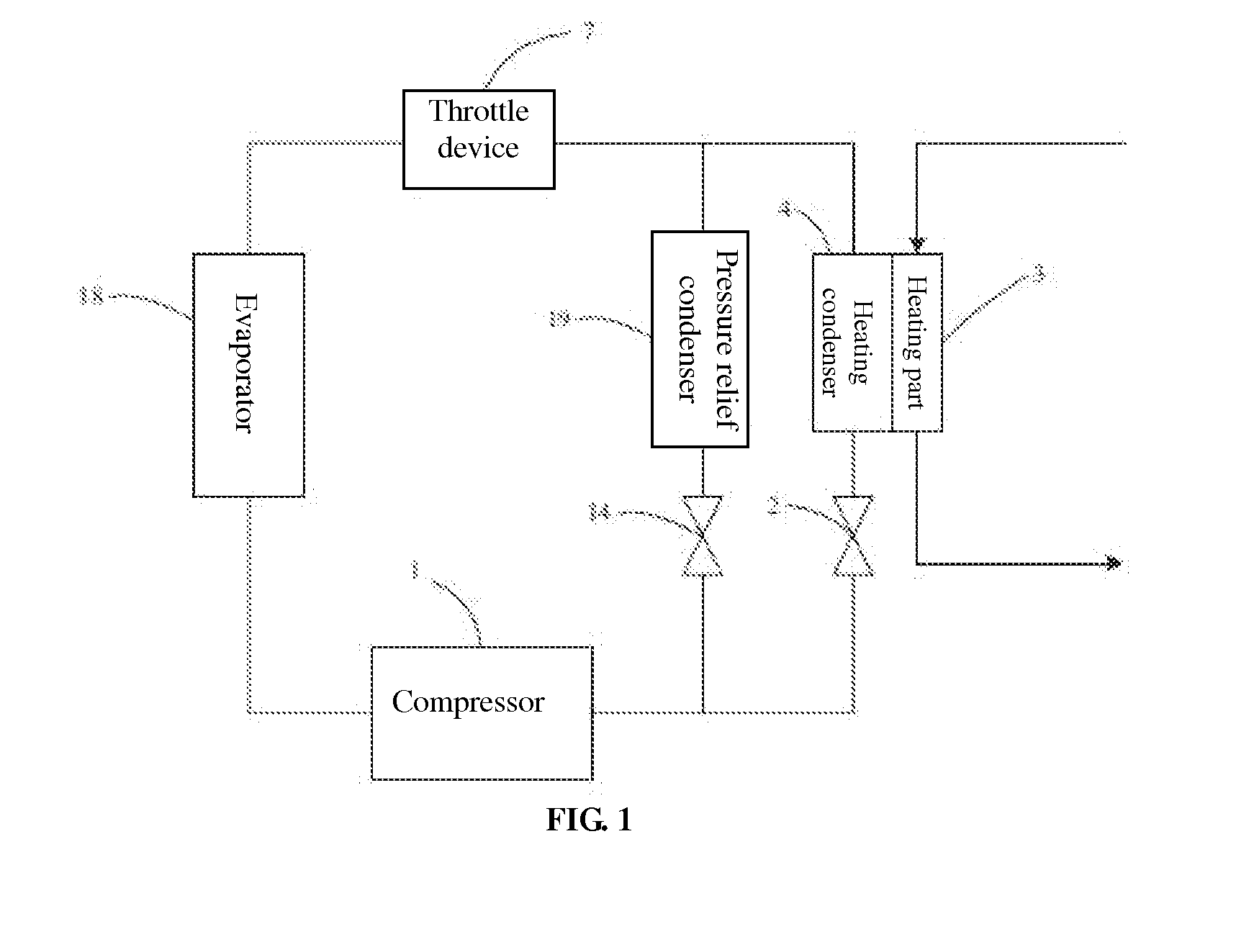

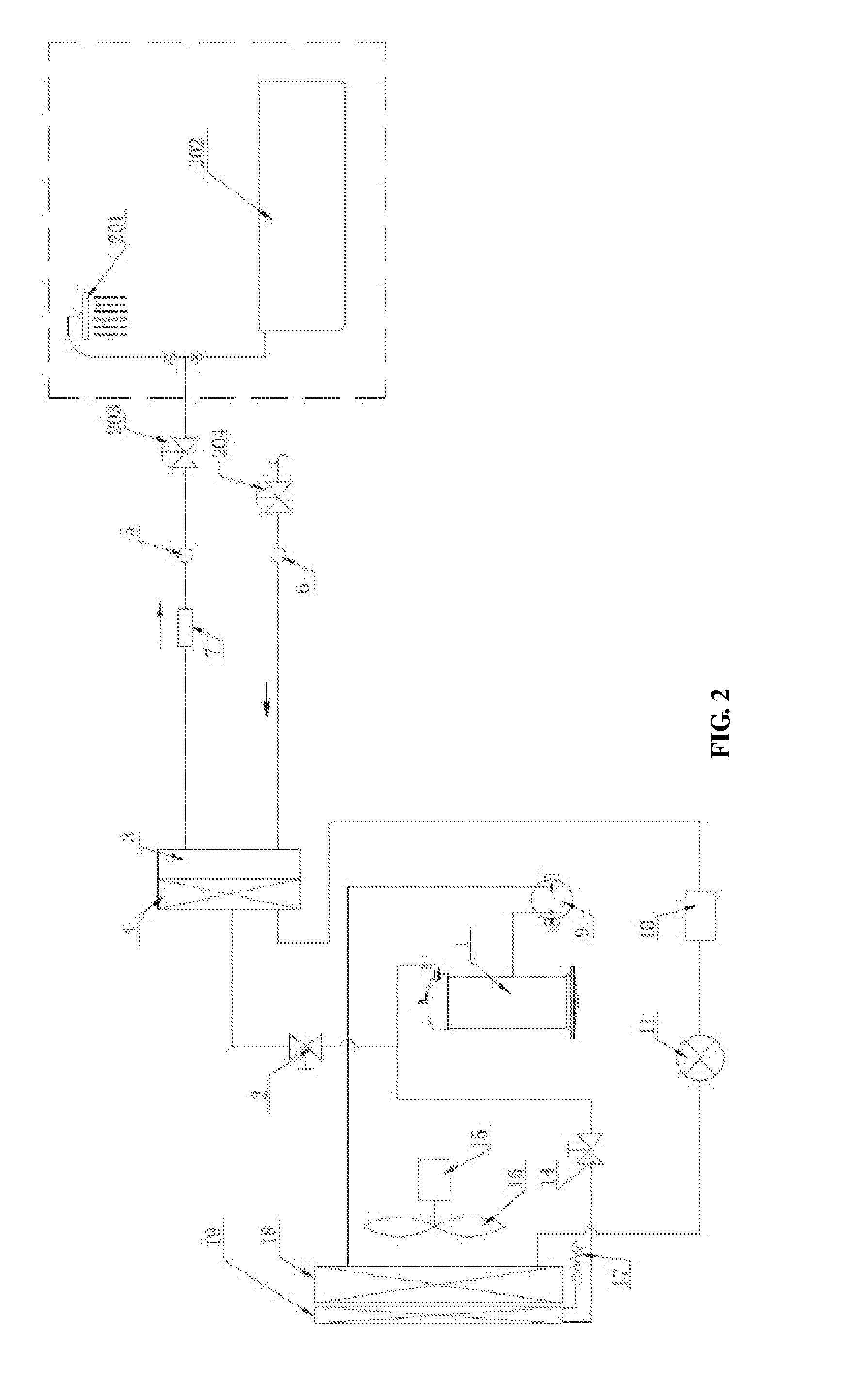

[0030]As shown in FIG. 1 and FIG. 2, the present embodiment provides a tankless water heater, including a controller, a waterway and a heat pump circulation loop;

[0031]In the water-flowing direction, the waterway successively includes: an inlet 6, a heating part 3 and an outlet 5;

[0032]The heat pump circulation loop successively includes: a compressor 1, an evaporator 18, a condenser and a throttle device 7, wherein the compressor is in control connection with the controller, and the condenser includes a heating condenser 4 and a pressure relief condenser 19, wherein the heating condenser 4 is in heat conduction contact with the heating part in the waterway and is set in series with the pressure relief condenser 19 in the heat pump circulation loop, besides, a heating condenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com