Method and apparatus for treating natural gas and oil well waste waters for removal of contaminants and dissolved solids

a technology of natural gas and oil wells, applied in the nature of treatment water, multi-stage water/sewage treatment, waste water treatment from quaries, etc., can solve the problems of reducing the saline content of waste water, limiting the means and/or increasing the cost of storage of water for reuse or awaiting disposal, and water may not be readily and/or cost effective disposed of in injection wells. , to achieve the effect of high flexibility and reducing the saline content of was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

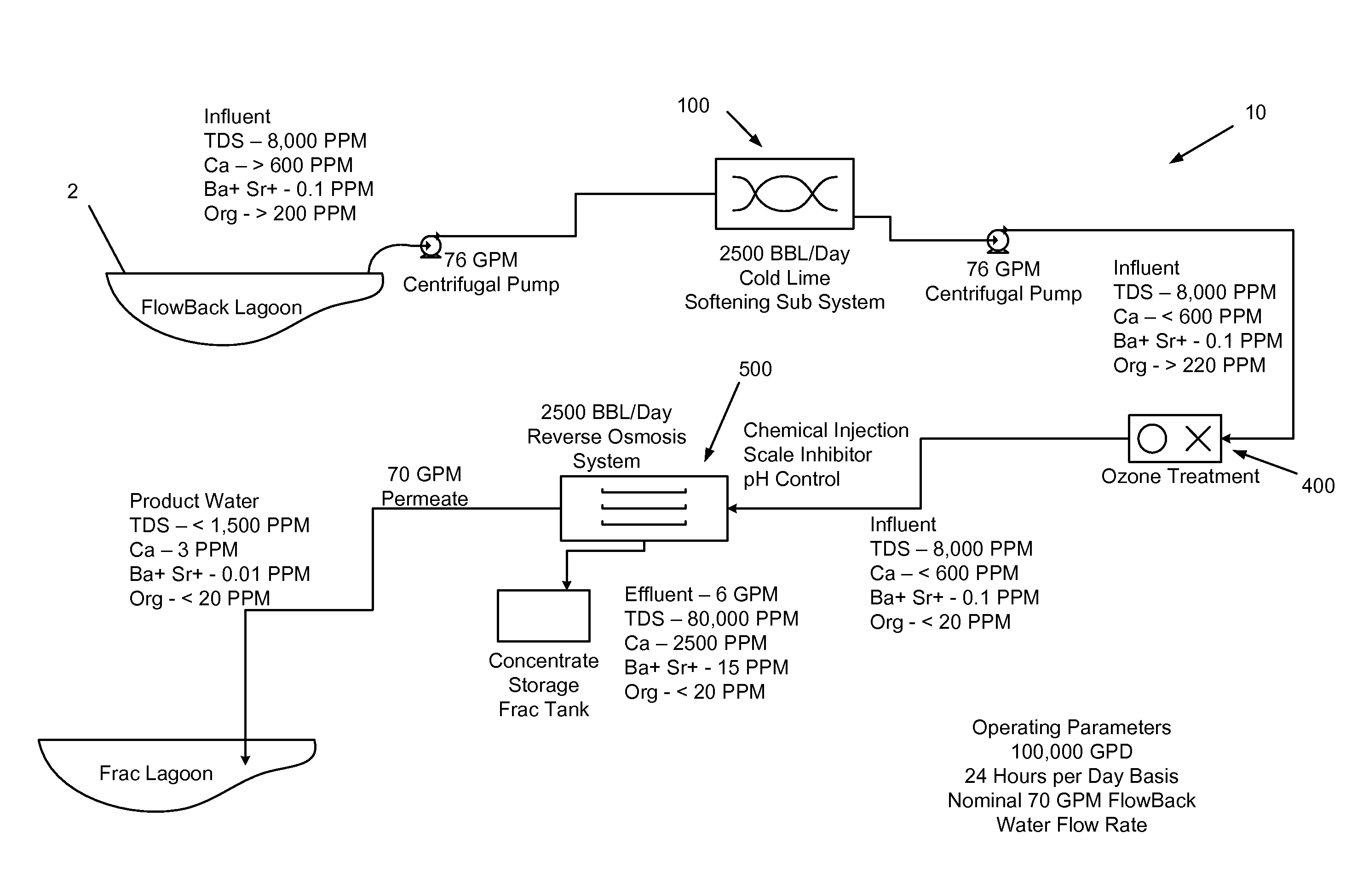

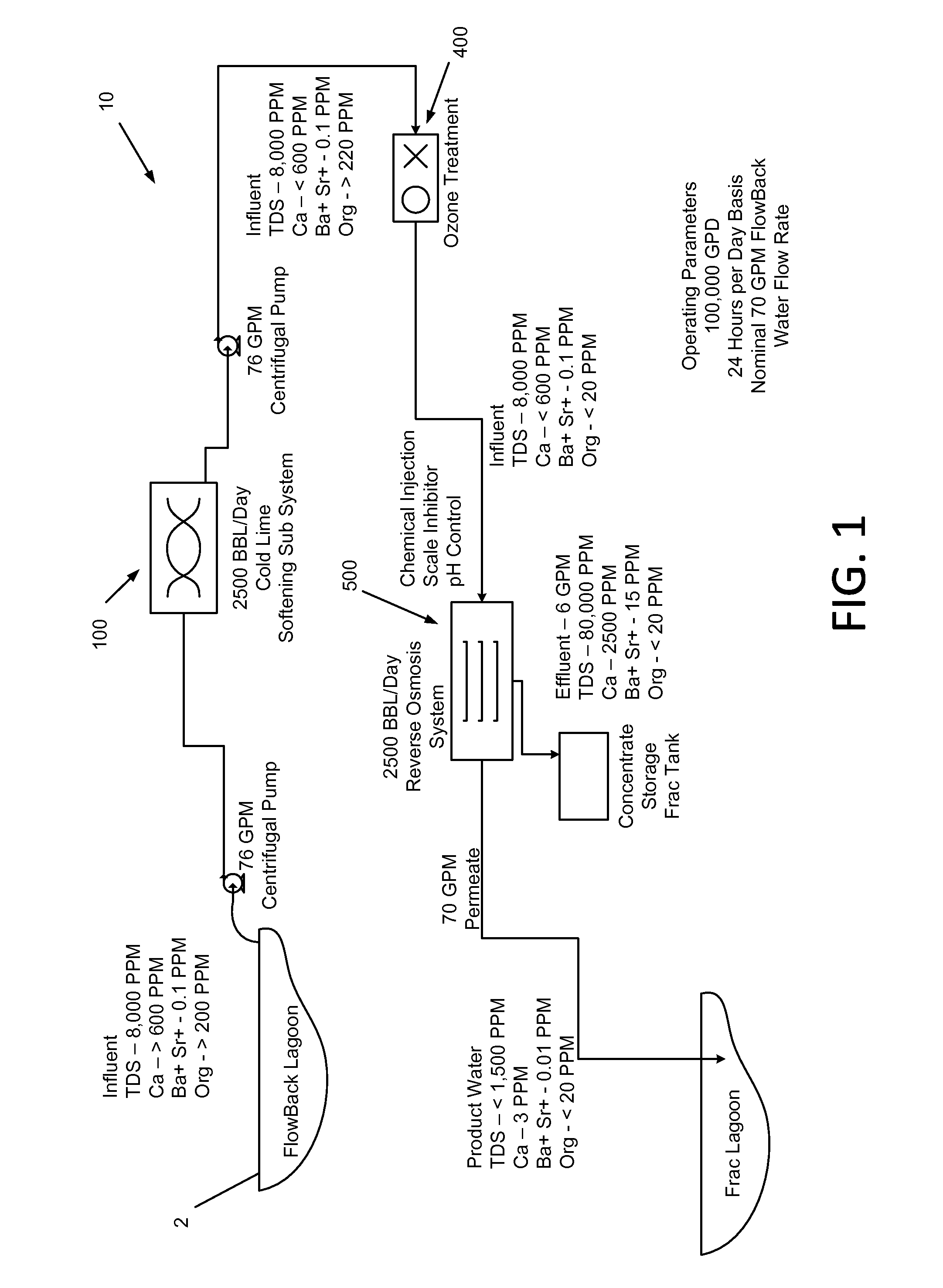

[0049]Referring first to FIG. 1, the Applicants' apparatus for treating natural gas and oil well waste water is comprised of a pretreatment system for removal of dissolved and suspended organic matter and suspended inorganic matter in a manner similar to that disclosed in the aforementioned patent application Ser. No. 13 / 461,871 of Miller, et al., a cold soda lime softening subsystem 100, an ozone treatment subsystem 400, and a reverse osmosis system 500.

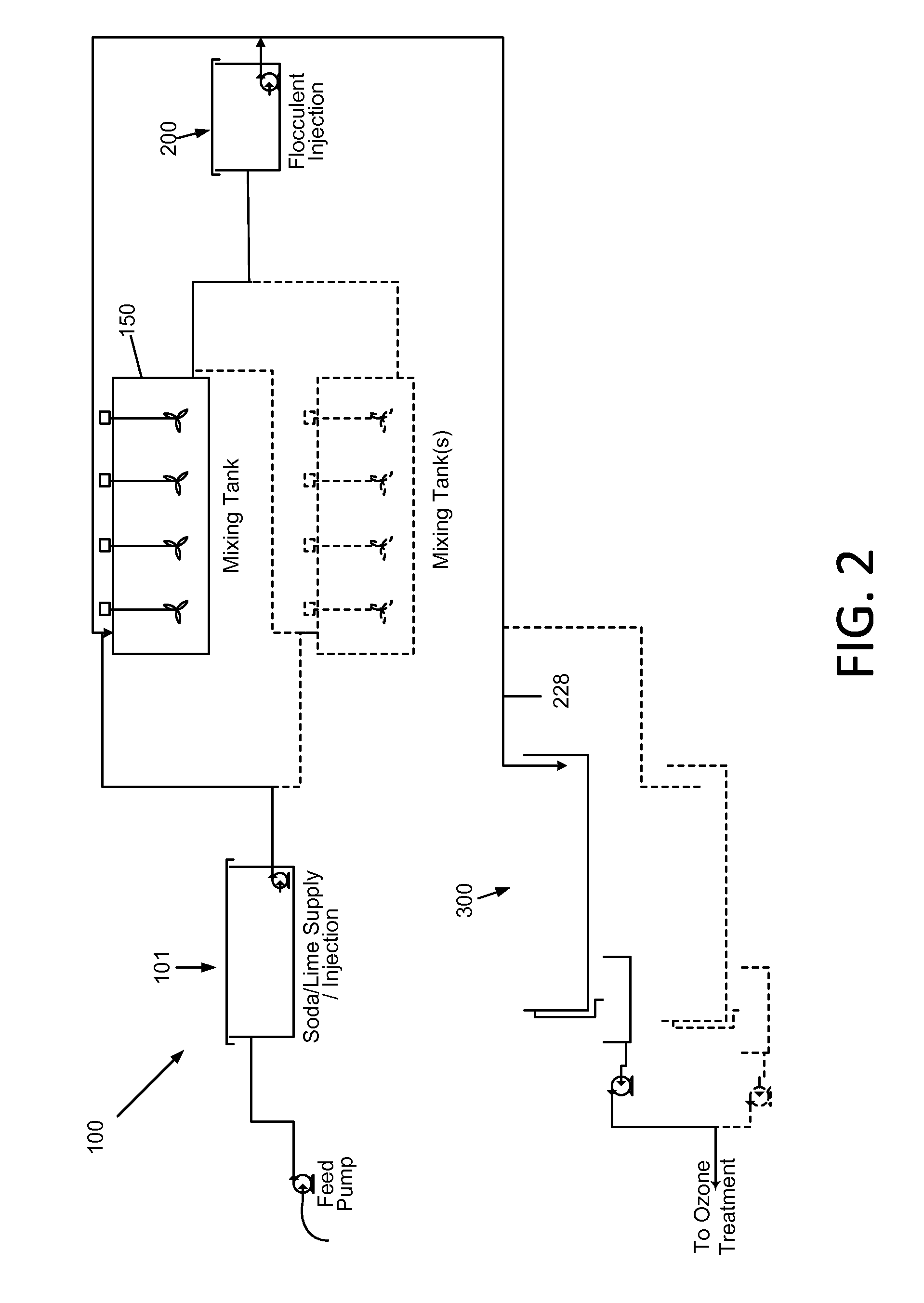

[0050]The pretreatment system is not shown in FIG. 1, but is provided between the wastewater lagoon 2 and the softening subsystem 100. The pretreatment system will now be described, as disclosed in patent application Ser. No. 13 / 461,871 of Miller, et al., as well as Patent Cooperation Treaty (PCT) Application No. PCT / US2012 / 036050, the disclosure of which is incorporated herein by reference. The remainder of the Applicants' methods and apparatus will then be described with reference to FIGS. 2-13.

[0051]The pretreatment system may fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com