Process and plant for at least partial gasification of solid organic feed material

a solid organic feed material and gasification technology, applied in the direction of gas dust removal, combustible gas production, combustible gas purification/modification, etc., can solve the problems of reducing the overall efficiency of the plant, all residual coke can be recirculated, etc., to achieve high surface area, low mass, and high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

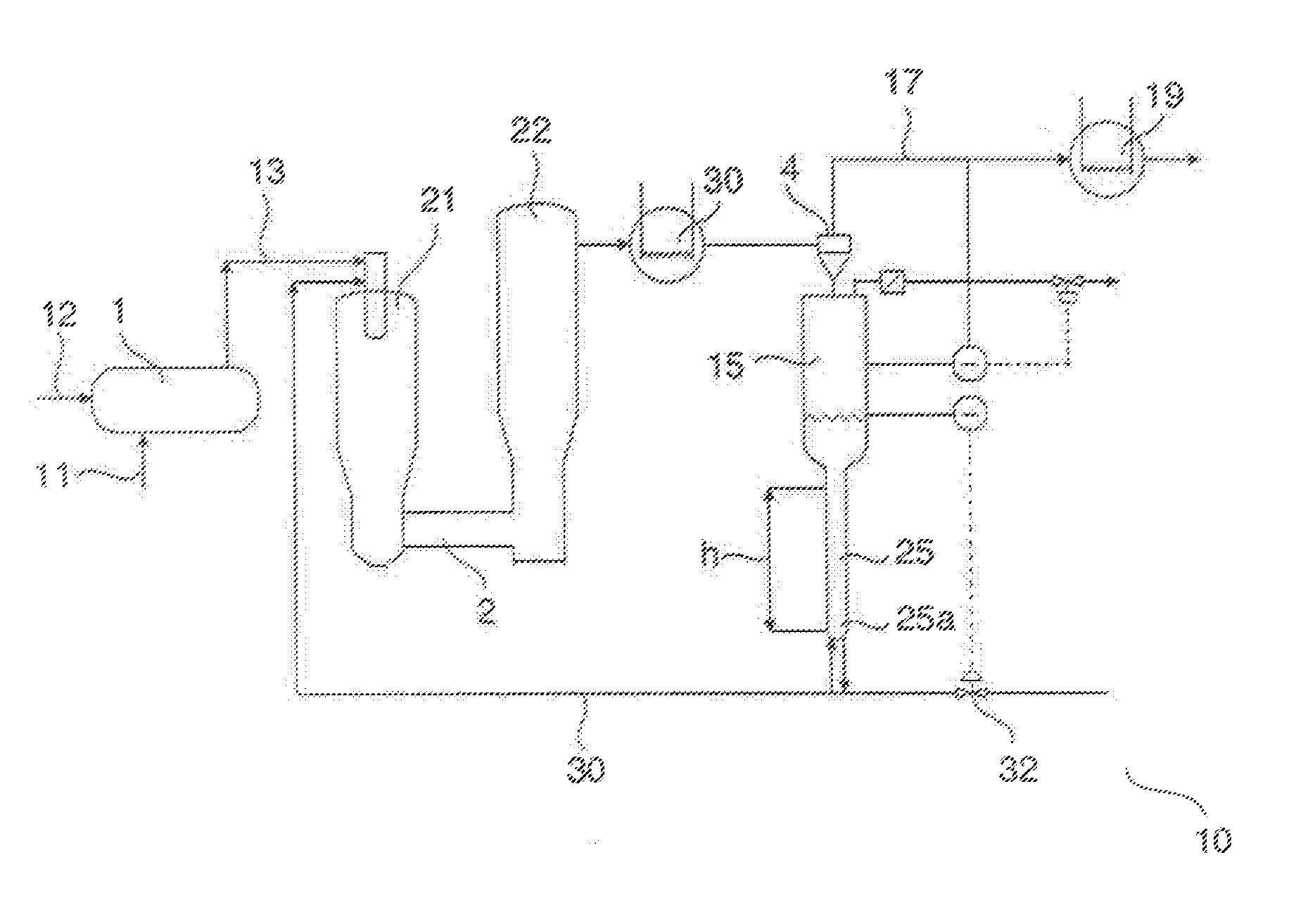

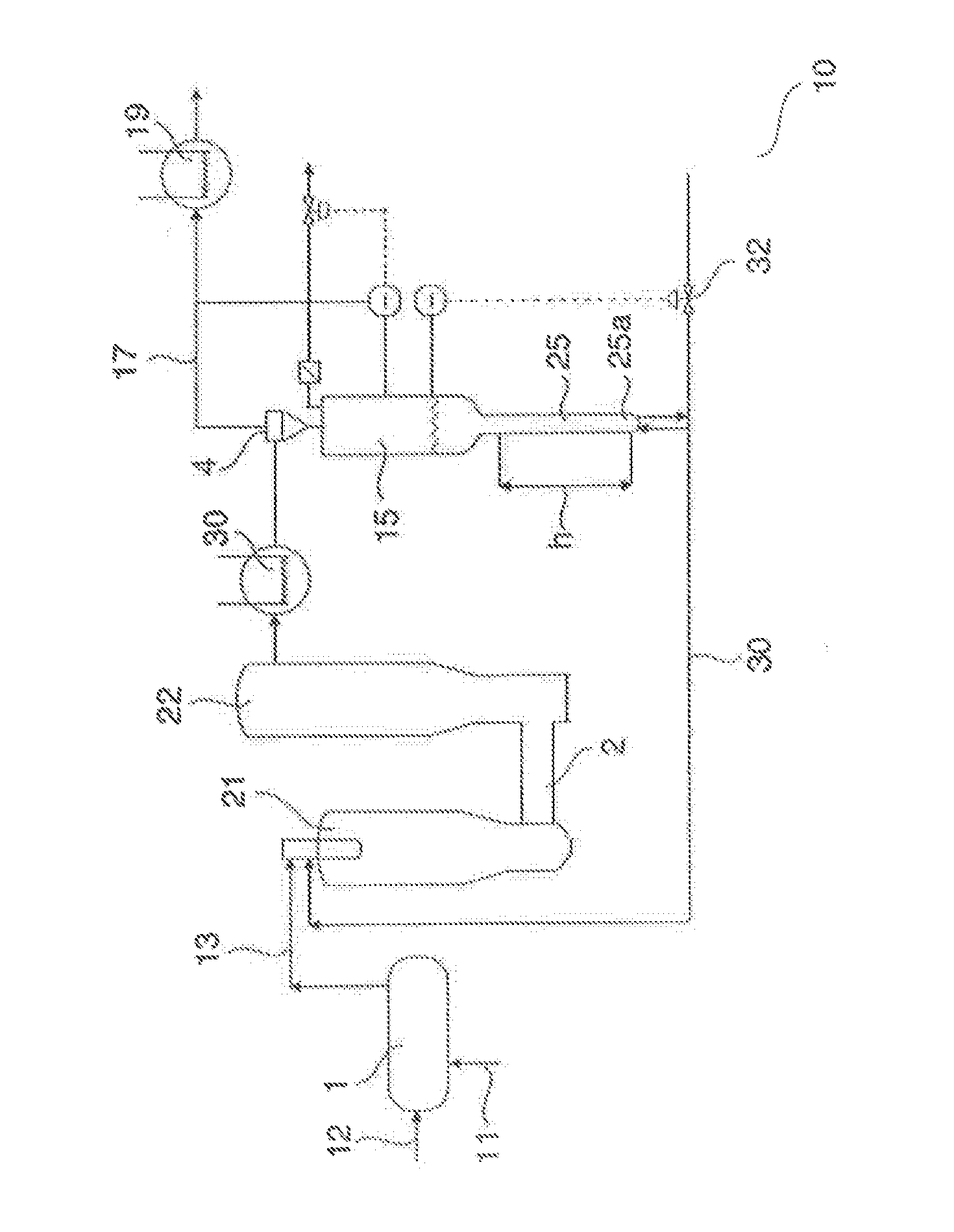

[0025]FIG. 1 shows a plant which is equipped for carrying out a process according to the invention, and is designated overall by 10. The plant 10 comprises a low-temperature gasifier 1 and a high-temperature gasifier 2.

[0026]A feed material, for example biomass such as wood or corresponding wastes, as explained above, can be fed into the low-temperature gasifier 1 (illustrated by means of arrow 11). Via a line 12, for example oxygen can be fed in. The low-temperature gasifier 1 is equipped for the low-temperature carbonization of the solid organic feed material A. For this purpose, the low-temperature gasifier 1 can be heated externally, for example with waste heat of the high-temperature gasifier 2, to a suitable temperature, for example 300° C. to 600° C. In a start-up phase of the plant, in this case, start-up burners of the high-temperature gasifier 2 can also be used.

[0027]Via a line 13, a low-temperature carbonization gas B can be passed out of the low-temperature gasifier 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com