Wall Mounted Zinc Batteries

a zinc battery and wall mount technology, applied in the direction of batteries, nickel accumulators, cell components, etc., can solve the problems of cadmium electrodes phasing out from mass production, nickel-cadmium storage devices that have replaced nickel-cadmium storage devices are more expensive than nickel-cadmium batteries, and achieve the effect of improving the design of replaceable and rechargeable zinc cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

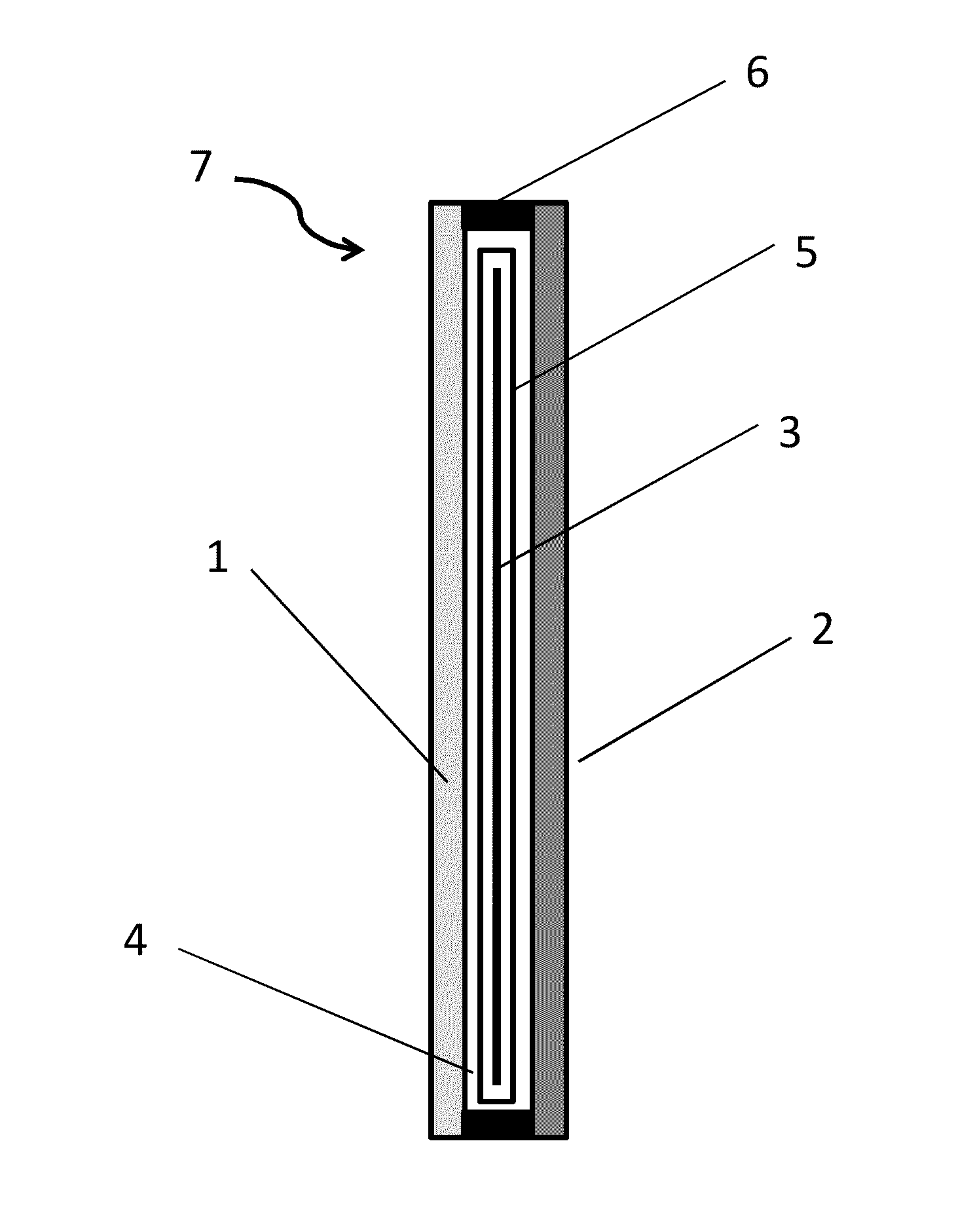

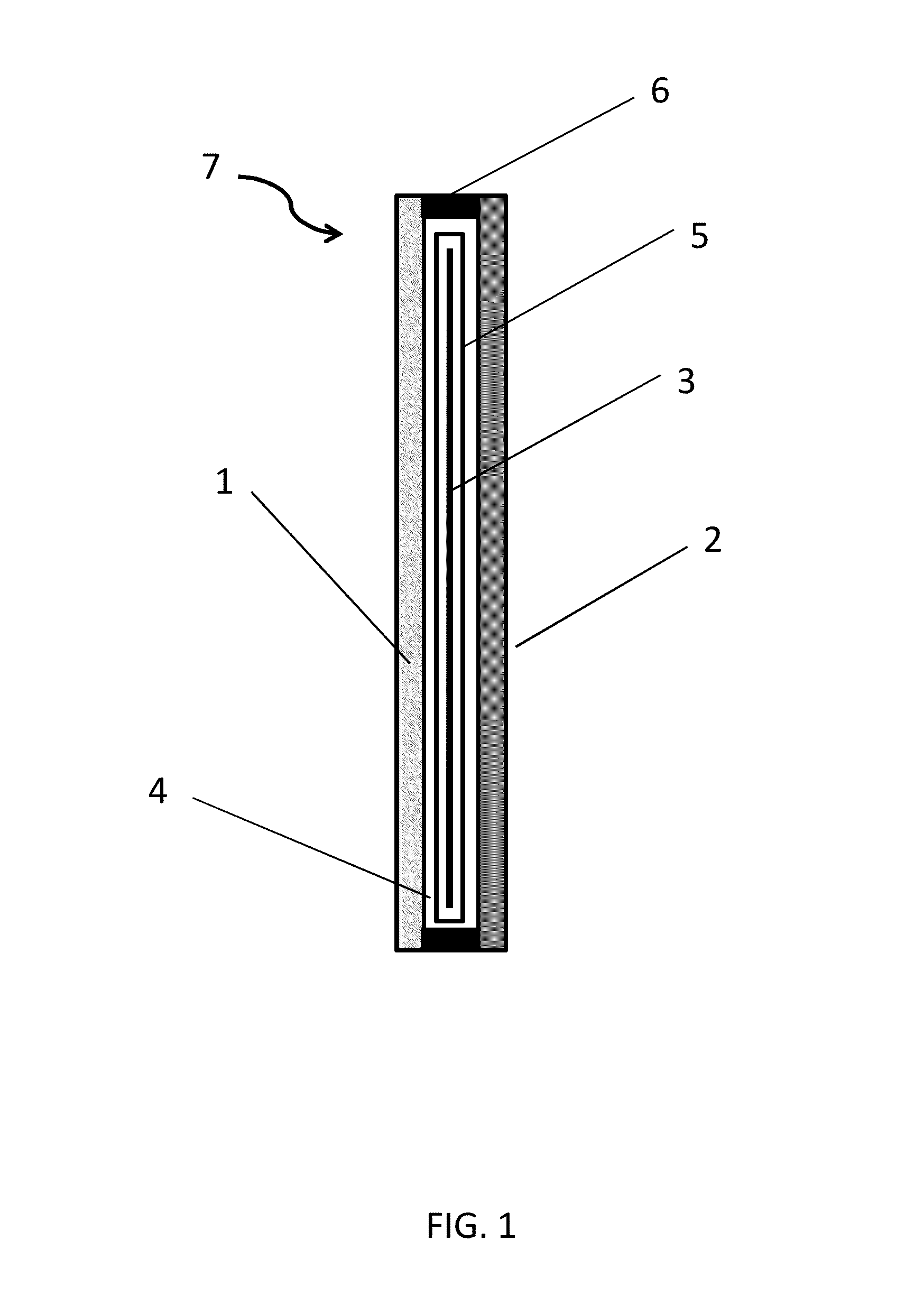

[0057]This example demonstrates a flat nickel-zinc battery designed with a wall mounted nickel-oxide hydroxide electrode, and a replaceable zinc cartridge. Zinc electrode current collector (4 cm*6 cm) has been produced by deposition of the Zn—Bi—Cu alloy with mass content 80% Zn, 20% Bi and 5% Cu on brass mesh 40 at 550° C. Electroactive zinc composition was prepared by mixing 8.1 g of zinc dust, 5 mkm size, 0.2 g of lead oxide, 0.2 g of m-aminodiphenylamine, 0.2 g zirconia hollow fibers, 0.2 g of ptfe dispersion, 0.1 g of carboxymethylcellulose with water. The mixture is deposited on brass current collector and wrapped into cellophane separator. The separator is sealed using double scotch.

[0058]Nickel electrode of the same size is prepared by welding nickel foam (pore diameters 0.3 mm-0.7 mm) to the nickel sheet 0.2 mm thickness; mixing 8.1 g of nickel oxide-hydroxide that includes 2% of ZnO and 5% of CoO with 1.5 g nickel powder, 0.2 g ptfe dispersion, 0.1 g carboxymethylcellulose...

example 2

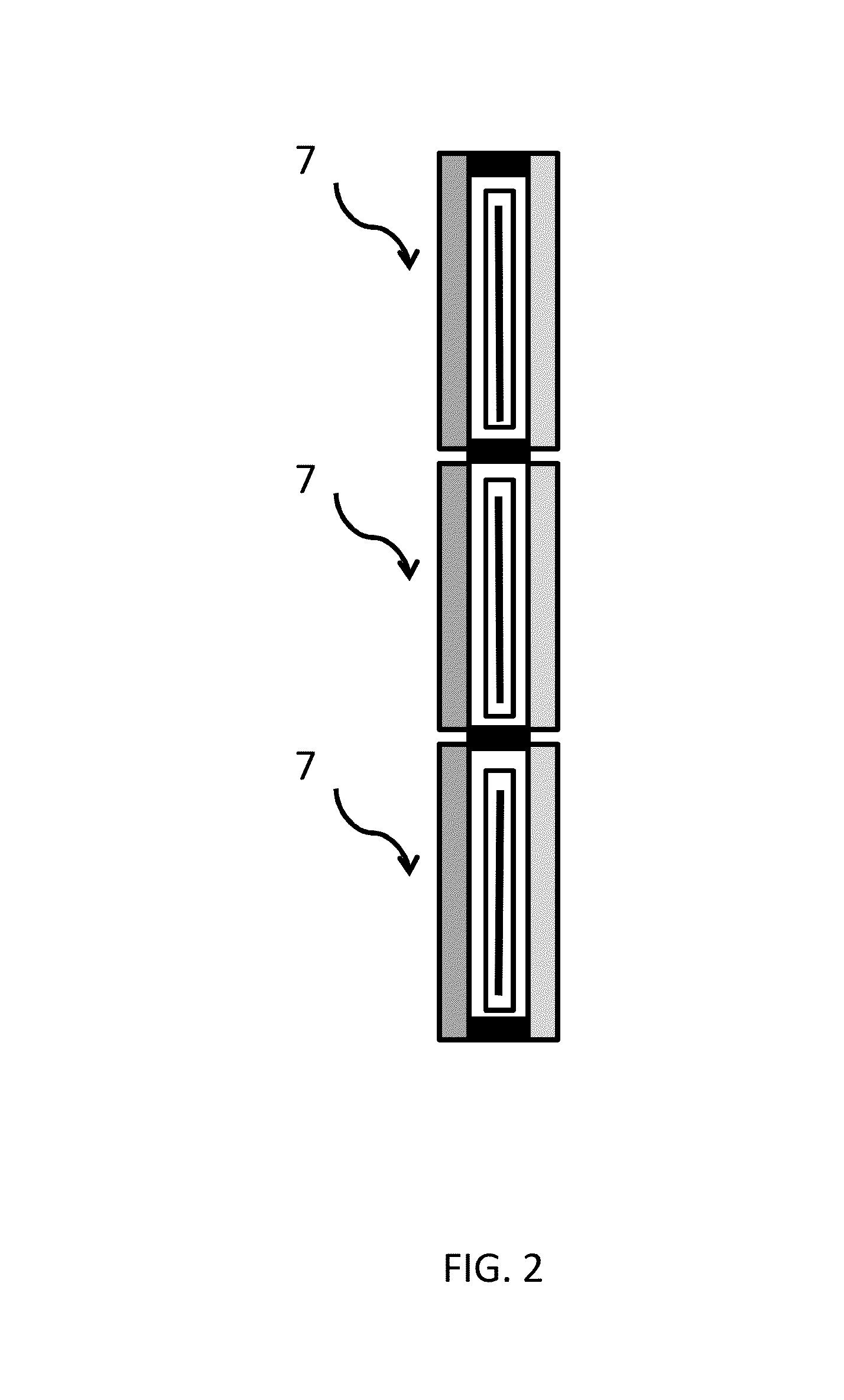

[0060]This example demonstrates assembling a module of three cell zinc-air battery, which is presented in FIG. 8. Three zinc cartridges have been produced similar to Example 1. The base of the module for three cells was assembled from two parts. One of the base sheets made of polypropylene was milled to produce the cell pockets and groves as shown in FIG. 4. Another base sheet was produced with pockets, but without grooves. Both sheets were glued with polyethylene based hot melt glue.

[0061]The air electrode catalyst was prepared by mixing 12 g of acid treated carbon black with 0.1 g-mol of m-phenylenediamine in 100 mL of 0.5M HCl solution. 0.05 g-mol ammonium persulfate and 0.05 g-mol FeCl3 were added to solution at 10° C. and mixed for 24 h. Produced precursor was dried, and heat treated at 800° C. for 1 h. Then the sample was leached in 0.5M H2SO4 at 80° C. for 5 h, washed and heat treated at 800° C. for 1 h again.

[0062]Three current collectors (4 cm*6 cm) were assembled by weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com