Image sensor, optoelectronic system comprising said image sensor, and method for manufacturing said image sensor

an optoelectronic system and image sensor technology, applied in the field of image sensors, can solve the problems of reducing the effective frame rate of the image sensor, blurring effects, and increasing the design requirements of the readout circuit, and achieve the effect of increasing the response of the photosensitive element as described in the claims, and enhancing the respons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

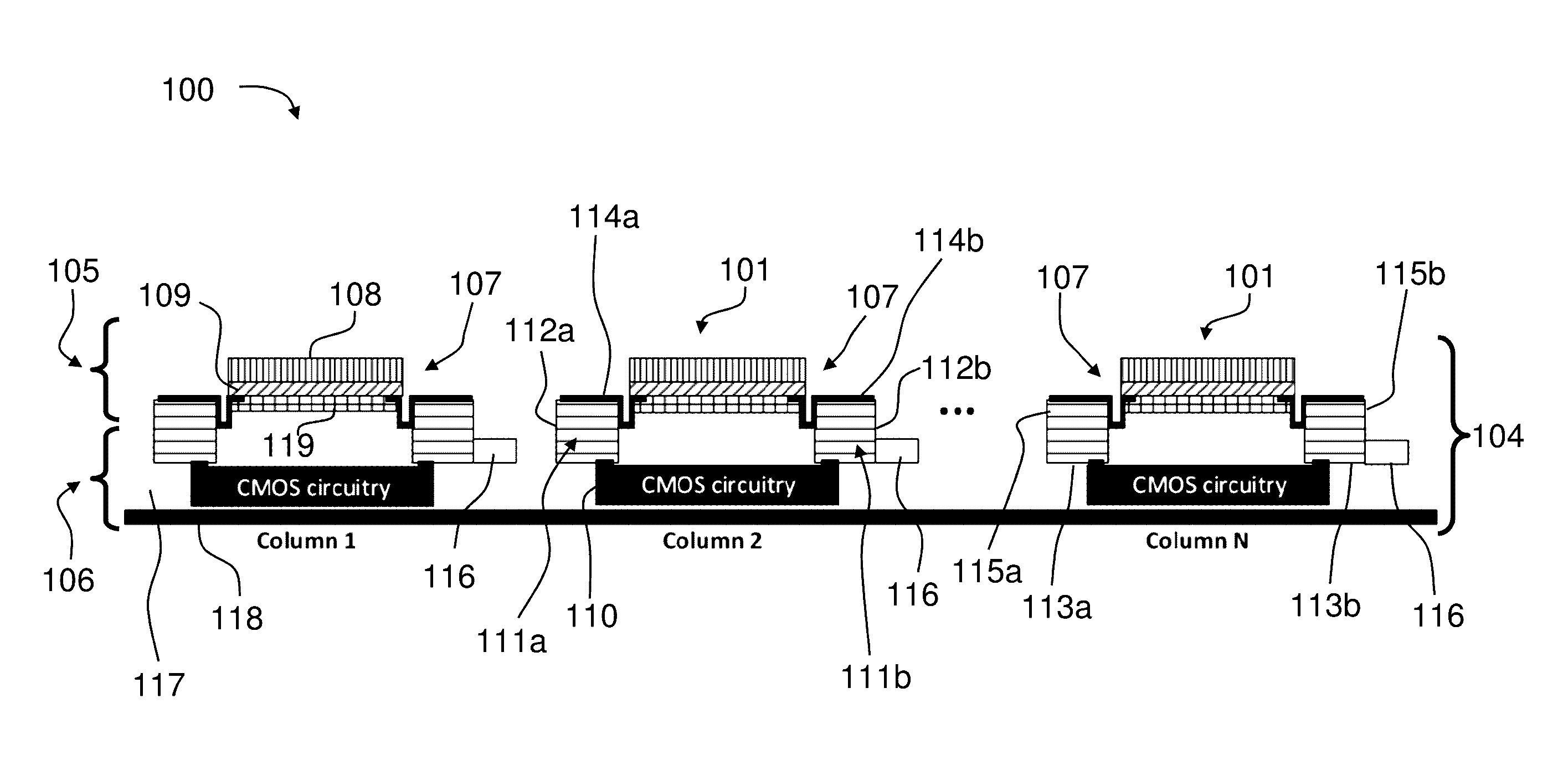

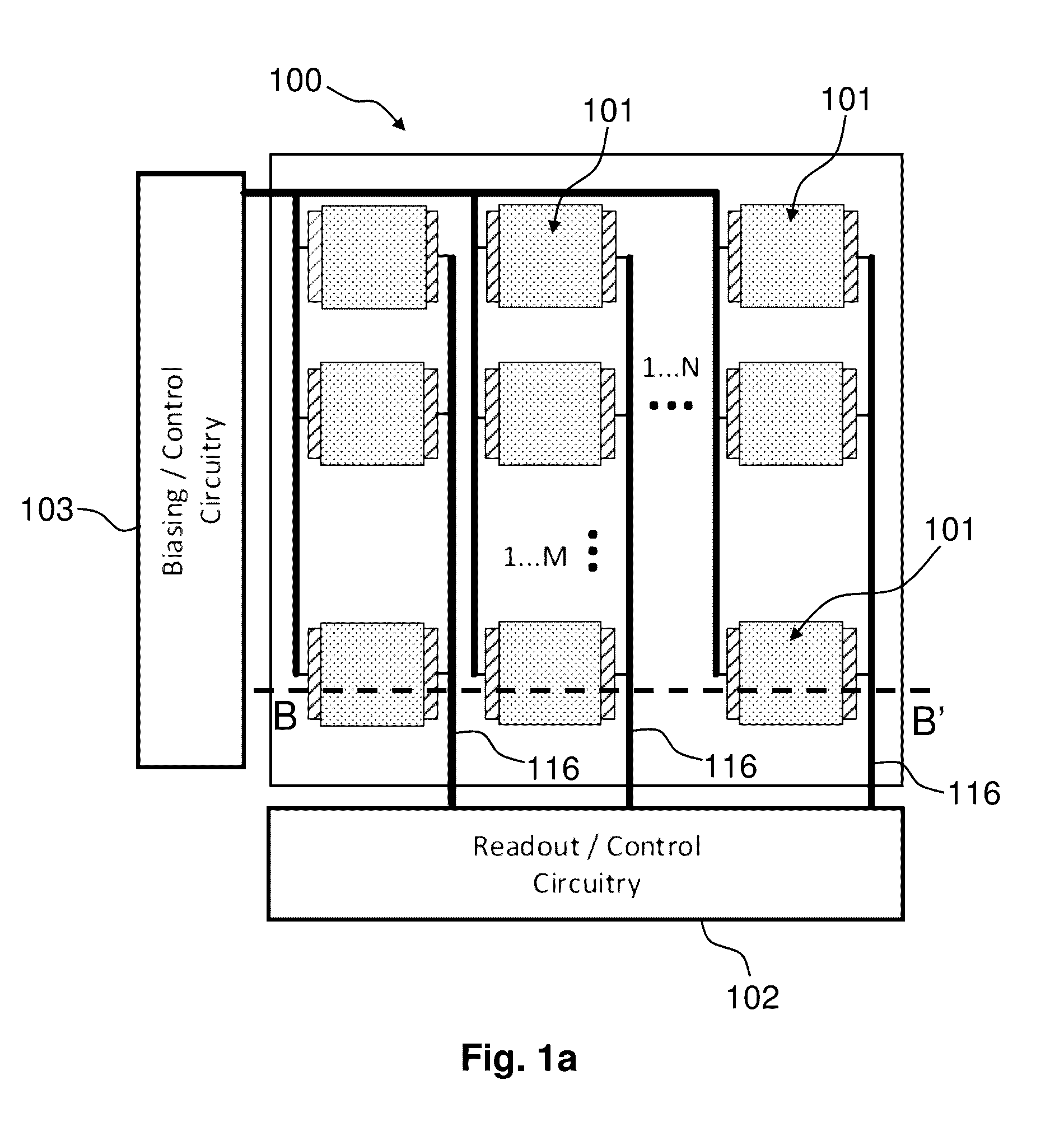

[0194]In FIG. 1a it is illustrated a top plan view of a block diagram of an embodiment of the image sensor according to present invention. In particular the image sensor 100 comprises a plurality of pixels 101 arranged as a two-dimensional array of M rows and N columns. The plurality of pixels 101 are operatively connected to a control unit that includes a biasing circuit 103 for biasing the plurality of pixels 101 and a readout circuit 102 for selectively reading out the photo-signals generated by the light impinging on the plurality of pixels 101.

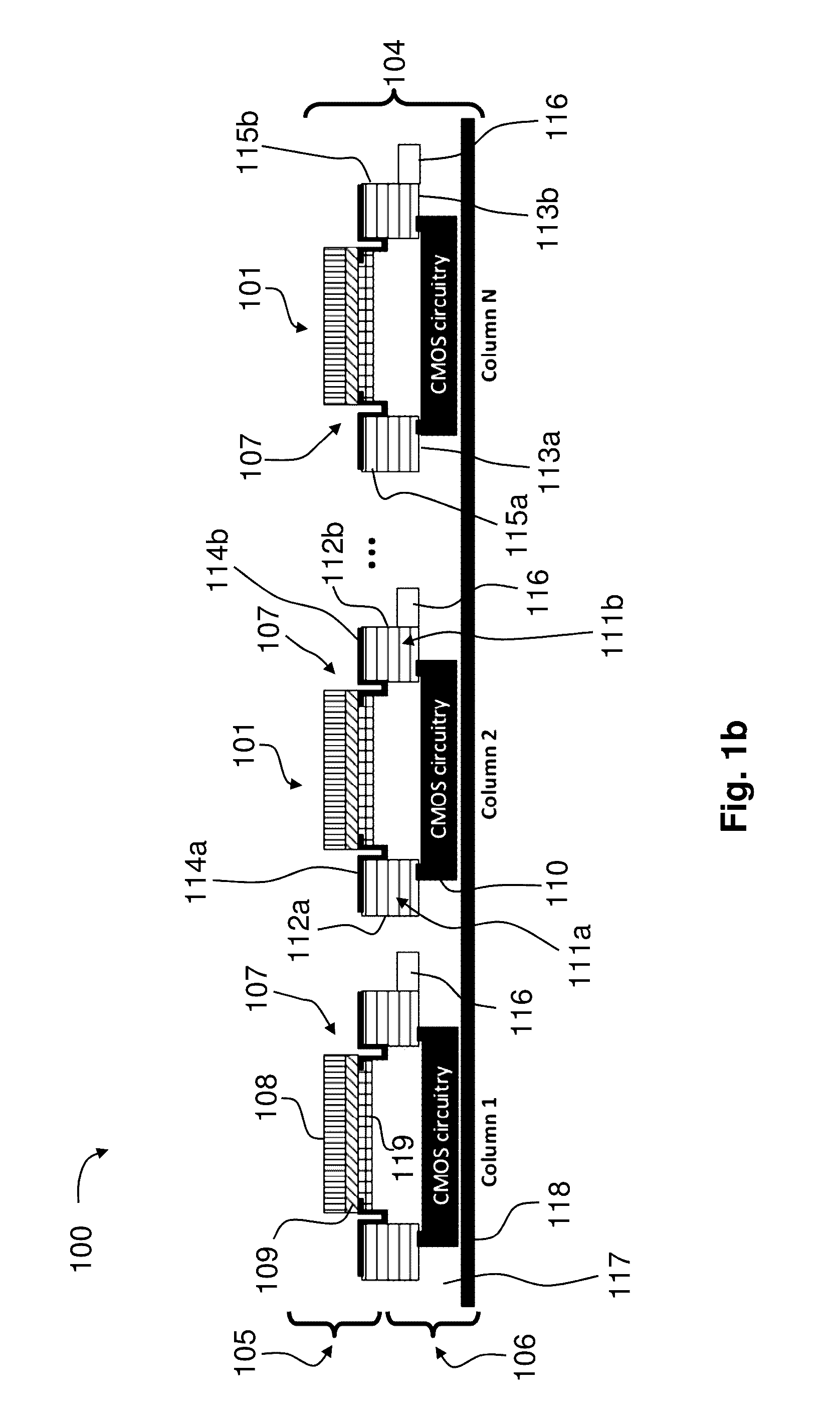

[0195]As it can be better seen in the cross-sectional view of FIG. 1b, the image sensor 100 comprises a monolithic three-dimensional integrated circuit 104 comprising an upper level 105 having a first plurality of stacked layers and a lower level 106, disposed underneath the upper level, having a second plurality of stacked layers.

[0196]Each pixel 101 of the plurality of pixels comprises a photosensitive element 107 arranged at a selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com