System and method for standardized modular construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example formulations

[0089]One WPC formulation which may be used for manufacturing extruded WPC profiles of the disclosure, can include a composition of:

[0090]from 35 to 65 wt % of a polyolefin, for example a virgin or newly produced High Density Polyethylene (HDPE) and / or a blend of virgin HDPE;

[0091]up to 10 wt % of recycled post-consumer HDPE, for example recycled bottles;

[0092]up to 10 wt % of a mineral filler, for example calcium carbonate or talc;

[0093]from 0.5 to 2.0 wt % of a non-metallic stearate lubricant;

[0094]from 1.0 to 3.0 wt % of a maleic coupling agent;

[0095]from 0.1 to 0.5 wt % of a thermal stabilizer comprising a blend of an organophosphate and a hindered phenolic antioxidant, the amount of thermal stabilizer dependent on the amount of post-consumer recycled content;

[0096]from 0.1 to 0.5 wt % of an ultraviolet stabilizer comprising a blend of an ultraviolet absorber and a hindered amine light stabilizer (HALS); and 5 to 15% Halogen-free flame retardants based on monoammonium and diammo...

example processing

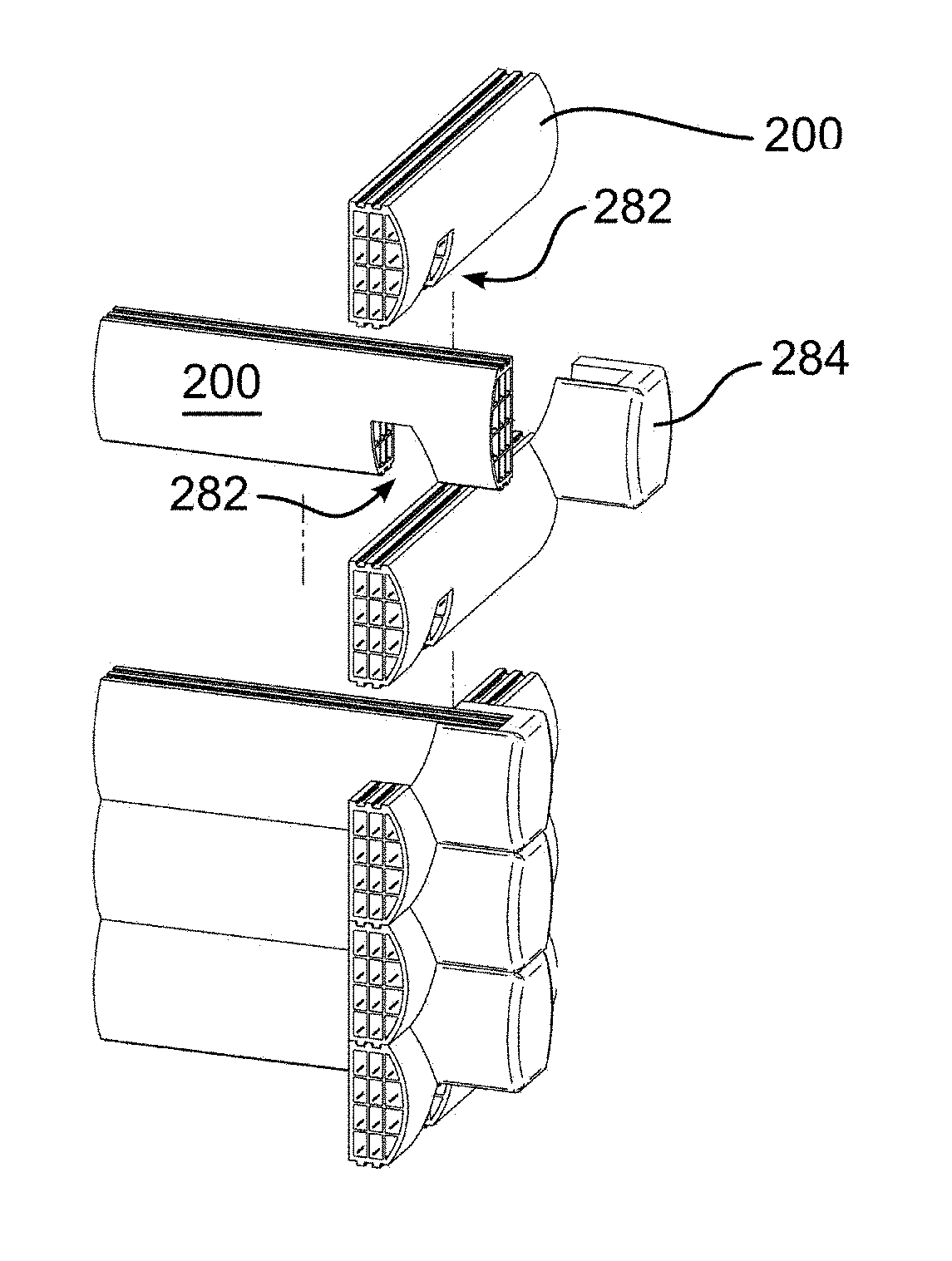

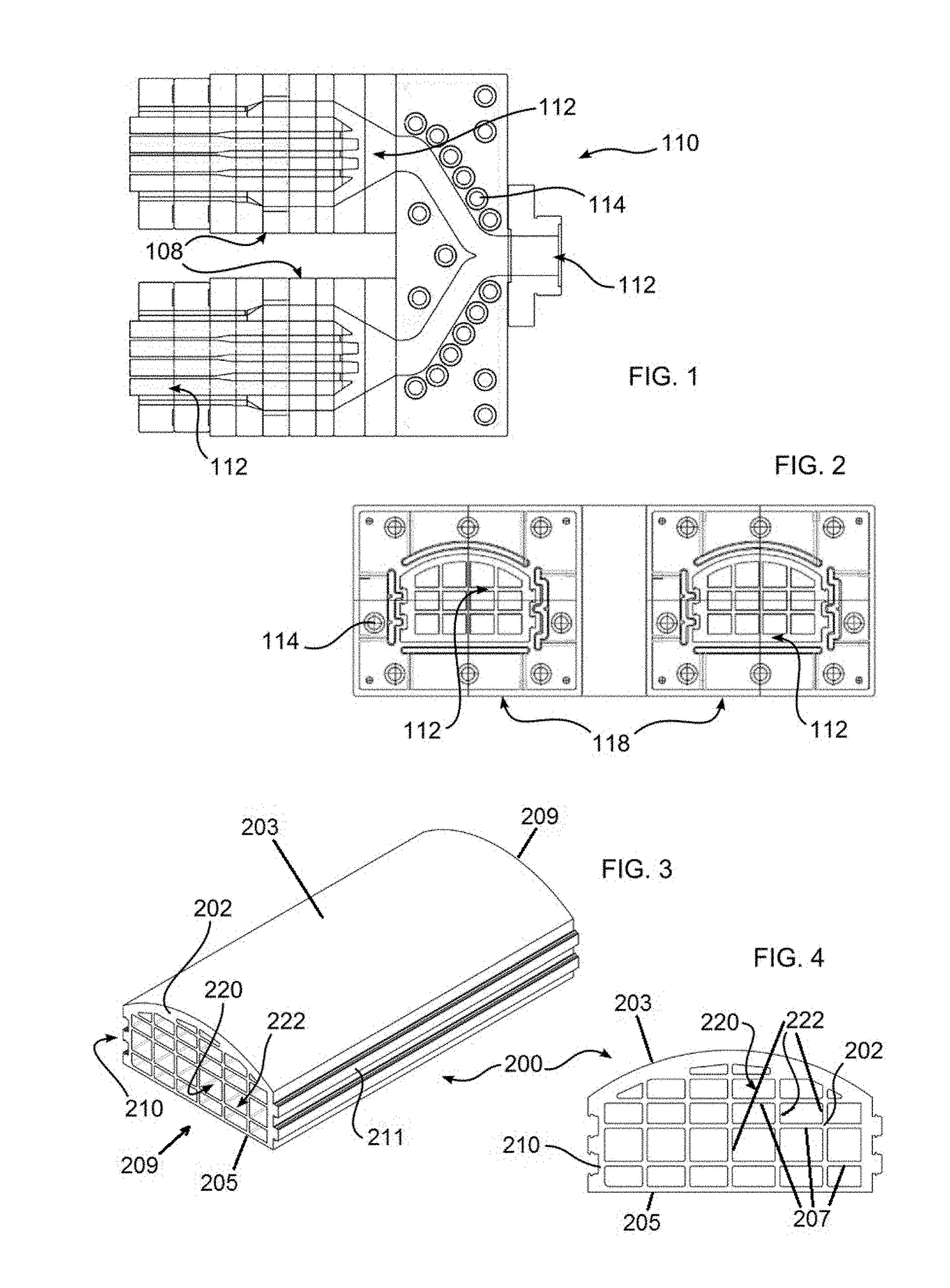

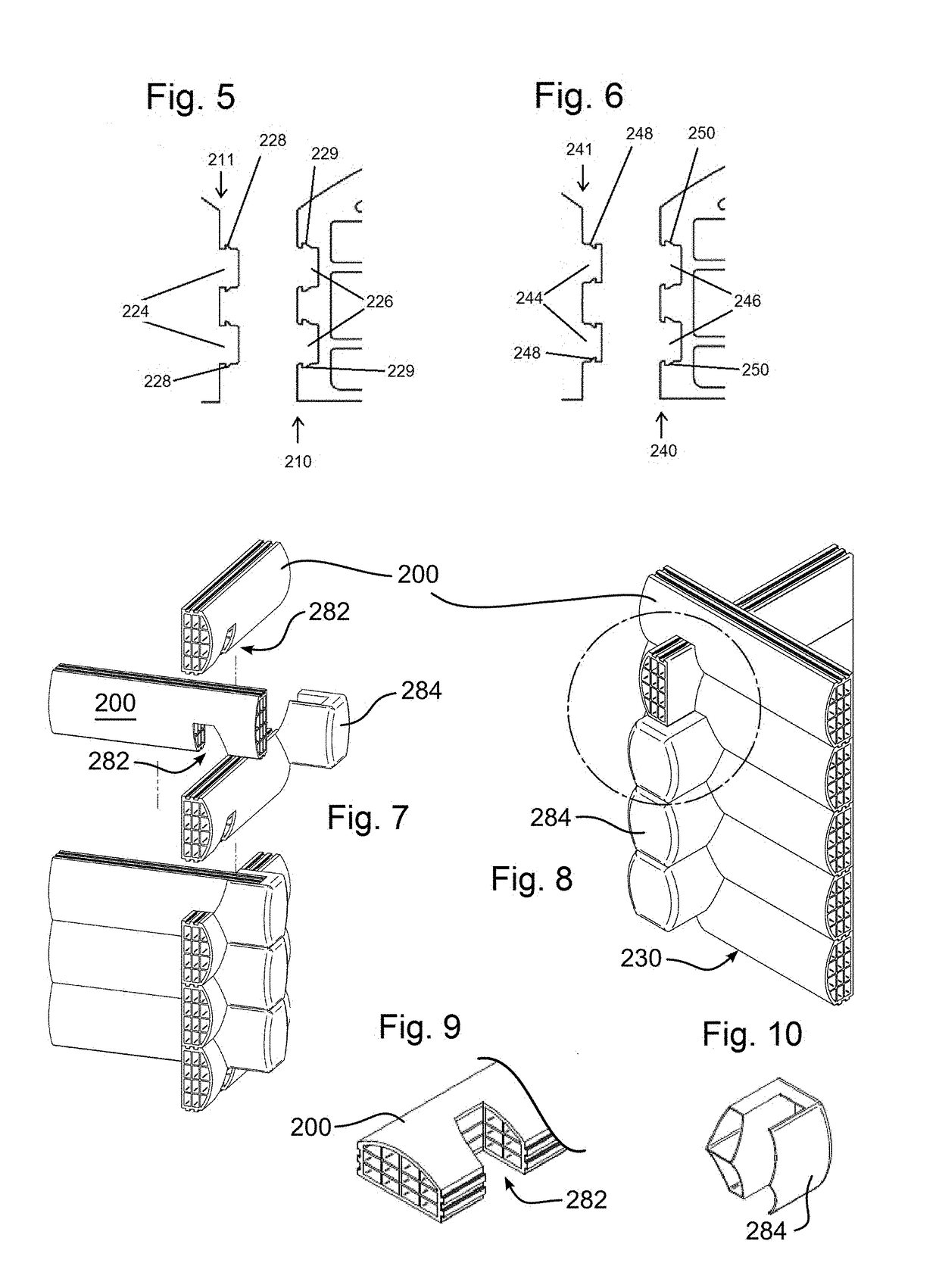

[0107]Using the foregoing example formulation, or other suitable WPC compositions, components cmay be produced in accordance with the disclosure using the following process. Processing of pelletized wood plastic composite is performed using a counter-rotating conical twin screw extruder, having a screw diameter front and rear of 92 and 188 mm, respectively. Five heating zones are provided in the barrel, and degassing means are positioned at half of the length of the screws. The counter-rotating twin screw extruder used in the invention was designed to meet throughput rates up to 2,600 lbs / hr. The screws have three distinct zones: feeding, conveying, and metering, which are designed to provide high head pressure capabilities and high torque for gentle plastification of the melt to feed the die shown in FIG. 1. The equipment is selected for heat and shear sensitive materials such as WPC. More particularly, it is desired to have a narrow residence time in order to produce optimal melt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com