Tool and method for direct squeeze casting

a direct squeeze and casting technology, applied in the field of direct squeeze casting tools and methods, can solve the problems of limited volume and prototype cast parts, high tooling costs for permanent mold processes, and designers relying on low volume sand cast parts, so as to improve heat transfer characteristics of casting, improve management, and improve thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

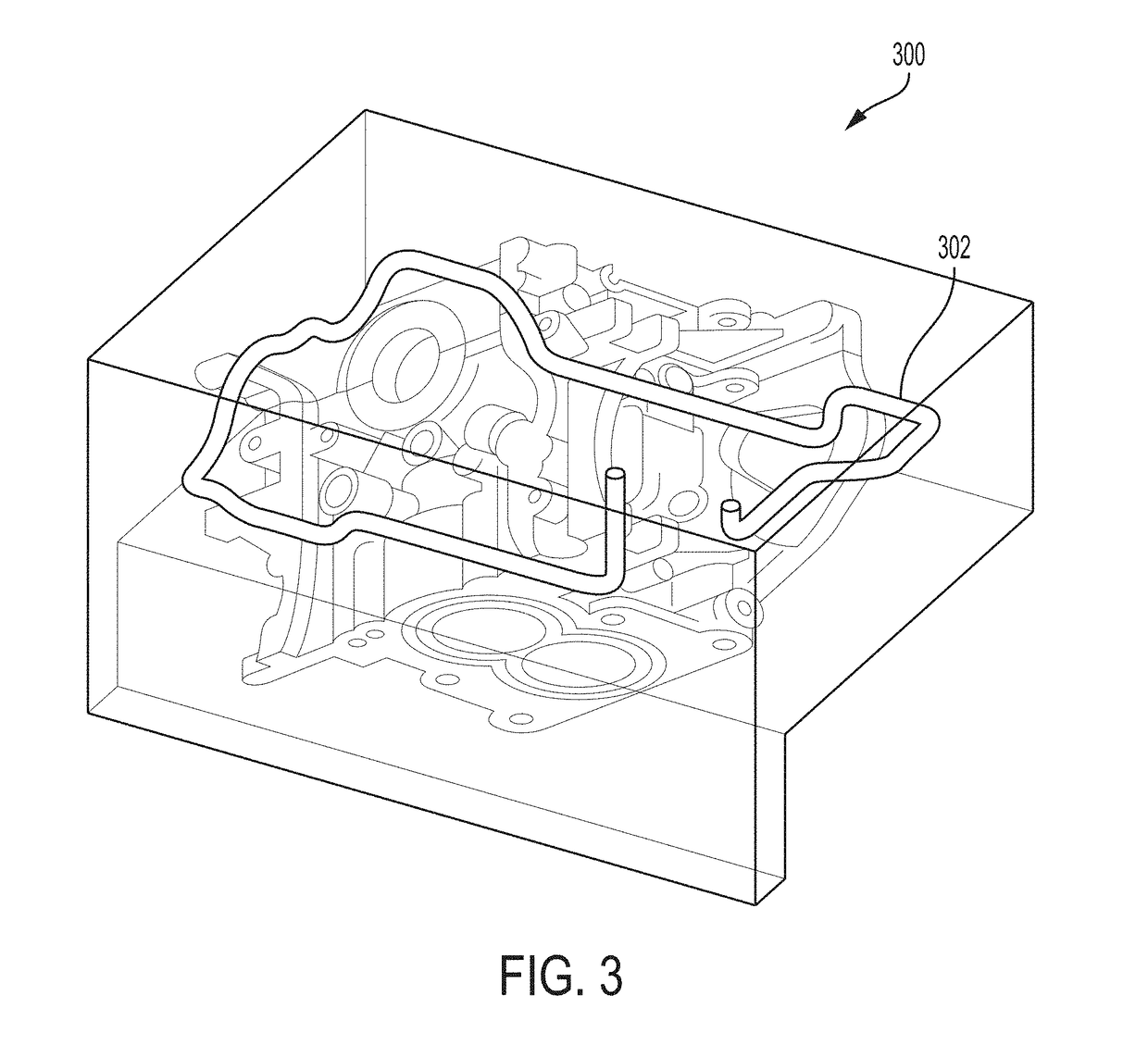

[0028]FIG. 3 is an interior view of an exemplary top mold tool 300 for a direct squeeze casting (DSC) system. The top mold tool 300 includes a curved internal passage 302. Unlike internal passages in conventional direct squeeze mold tools which are limited by machining methods to only including straight shaped sections, the internal passage 302 includes multiple curved sections. As is clearly illustrated, the internal passage 302 is quite complex and its shape has been optimized for the specific mold design to provide the highest quality molded part. In an exemplary embodiment, the complex and optimized internal passage is provided by forming the top mold tool 300 using a casting process which relies upon the use of a core to form the internal passage. A core is a device used in casting processes to provide internal passages having shapes and locations within the mold tool which may otherwise not be achieved through other methods, such as by a machining process.

[0029]FIG. 4 is a cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ductile | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure sensitive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com