Diamond like carbon layer formed by an electron beam plasma process

a plasma process and electron beam technology, applied in diamond, chemical vapor deposition coating, coatings, etc., can solve the problems of insufficient masking, insufficient pattern transfer, and inability to accurately transfer the pattern for the manufacture of structures having small critical dimensions and high aspect ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

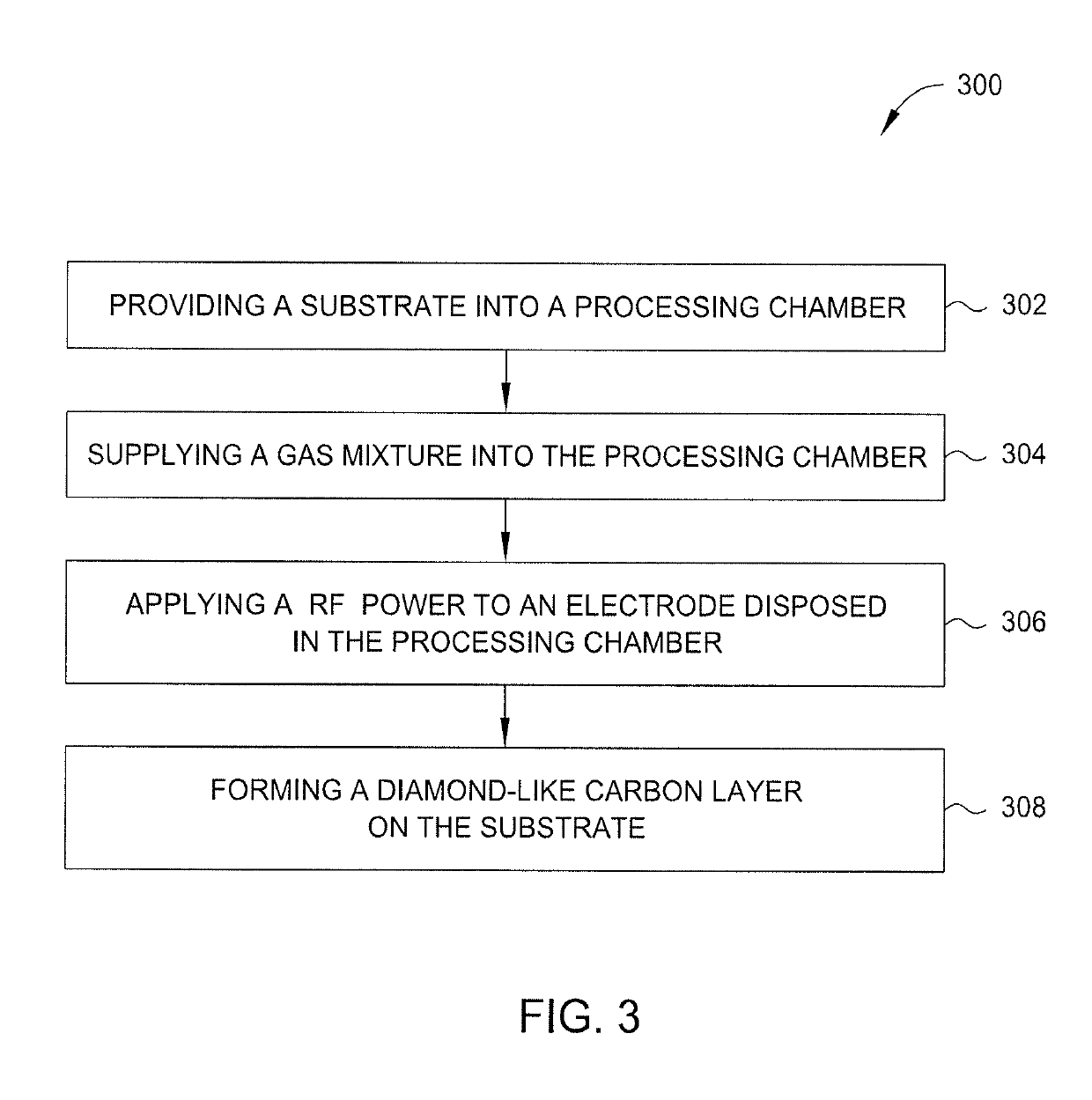

[0019]Embodiments of the present disclosure provide methods for forming a diamond like carbon layer with desired film properties, such as film transparency, mechanical strength, film hardness and low stress. In one embodiment, the diamond like carbon layer is suitable for use as a hardmask layer. The diamond like carbon layer with desired film properties may be obtained by an electron beam plasma deposition process. The electron beam plasma provides secondary electron beam required for depositing the carbon layer to form the carbon-like film structure with relatively strong bonding structure and mechanical strength. The diamond like carbon layer formed by the electron beam plasma maintains low stress level while having film density within a desired range. The diamond like carbon layer has optical film properties, such as a desired range of refraction index (n) and absorption coefficient (k), that are advantageous for photolithographic patterning processes.

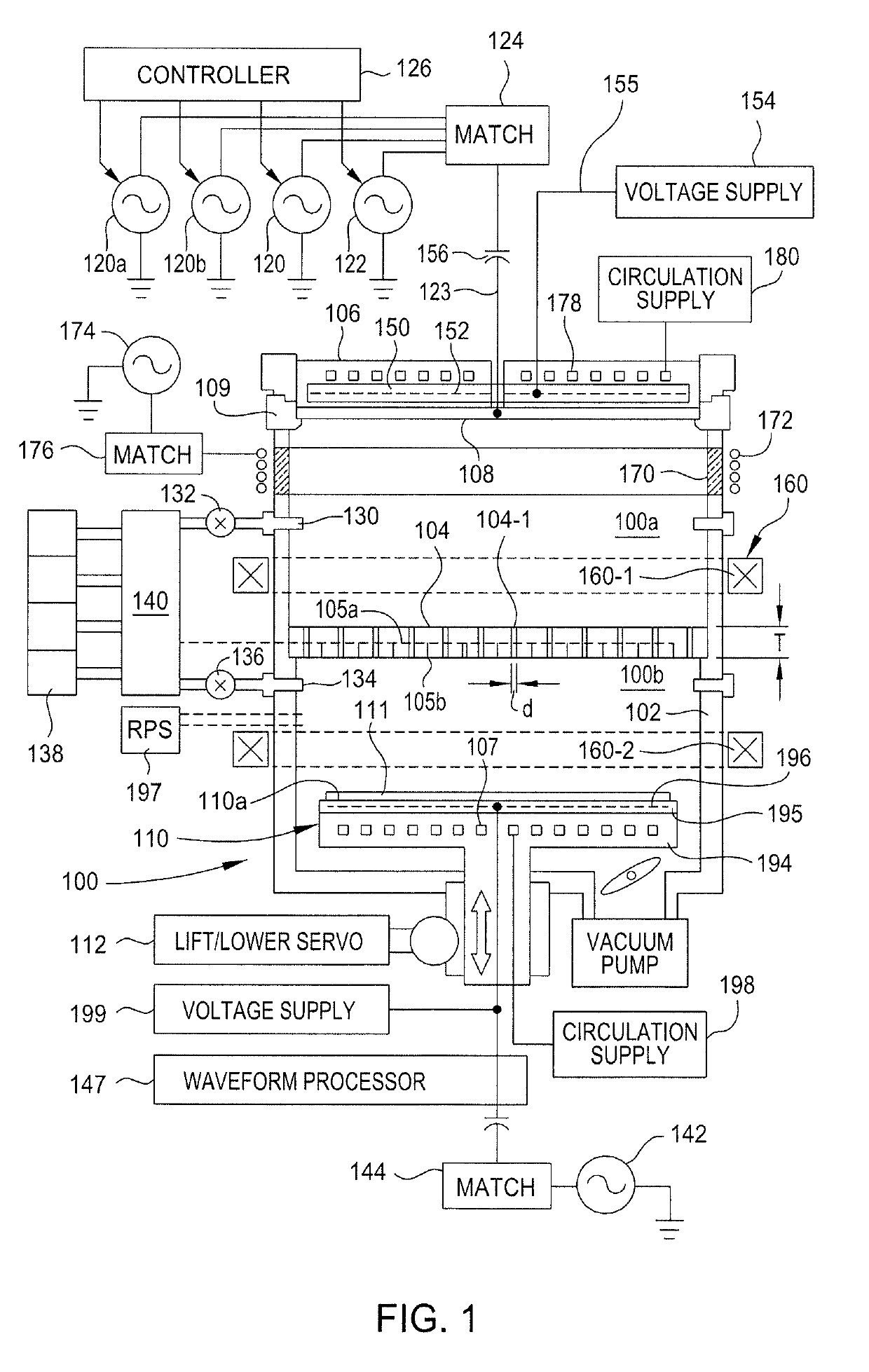

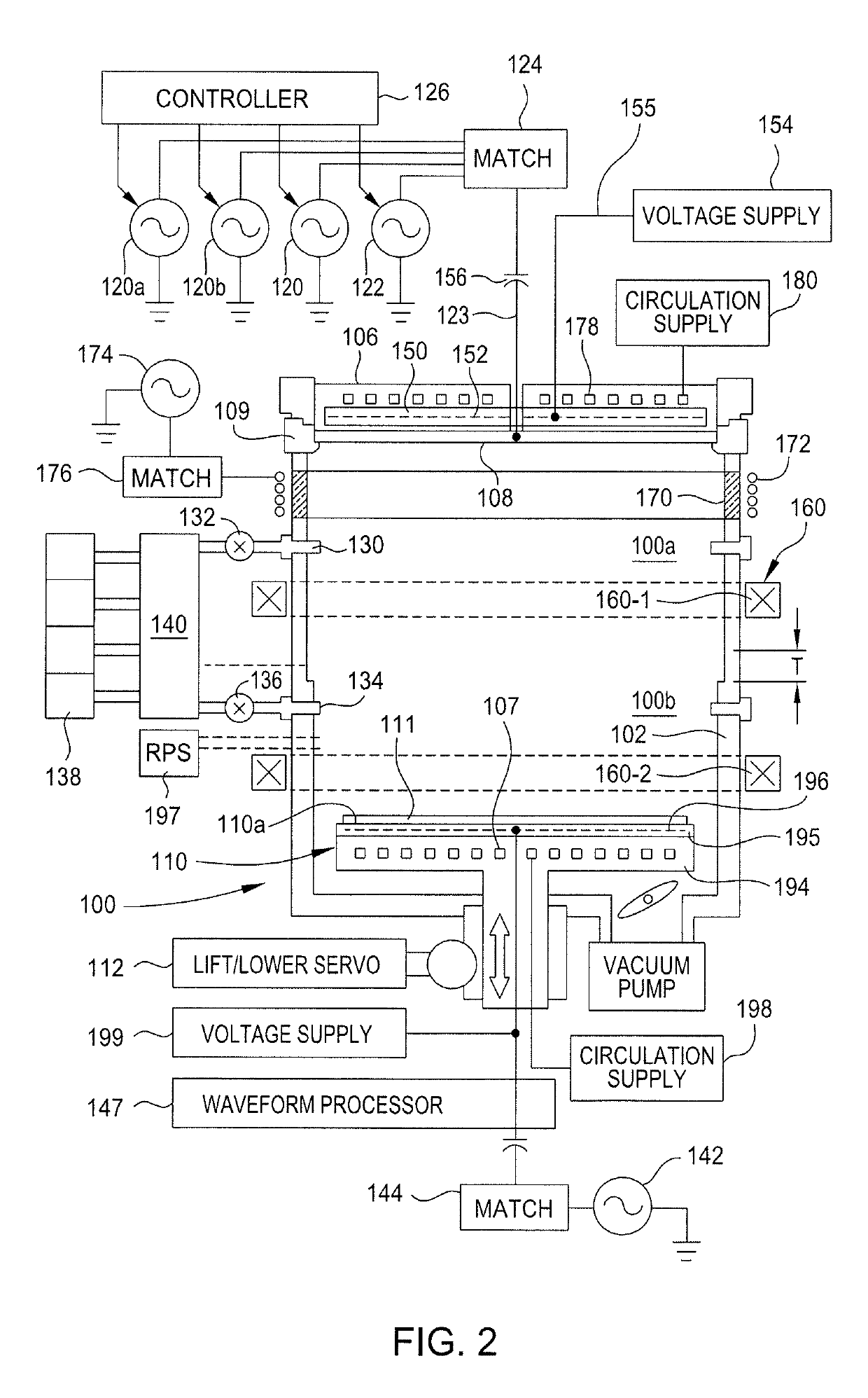

[0020]FIG. 1 depicts an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| output frequency | aaaaa | aaaaa |

| output frequency | aaaaa | aaaaa |

| electron energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com