Apparatus for electrochemically generating oxygen

a generator and oxygen technology, applied in the direction of electrolysis components, electrodes with substrates, electrolysis components, etc., can solve the problems of noise and vibration, related products are attracted attention, and the conventional oxygen generation technology such as the psa method or the membrane separation method is highly expensive, and achieves the effect of simple device configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0036]Advantages and features of the present invention and methods for accomplishing the same will be more clearly understood from embodiments described in detail below with reference to the accompanying drawings. However, the present invention is not limited to the following embodiments but may be implemented in various different forms. The embodiments are provided only to complete the present invention and to fully provide a person having ordinary skill in the art to which the present invention pertains with the category of the present invention, and the present invention will be defined by the appended claims.

[0037]Hereinafter, specific contents for carrying out the present invention will be described in detail with reference to the accompanying drawings. The same reference numeral indicates the same element regardless of the drawings. With respect to the elements referred using the term of “and / or”, each of the elements and all possible combinations of the elements are included ...

experimental example 1

[0115]On a nafion electrolyte membrane, Pt / C as a catalyst was applied on a cathode, and an iridium oxide catalyst having a nanoporous structure was applied on an anode using a spray method, a decal method, or the like.

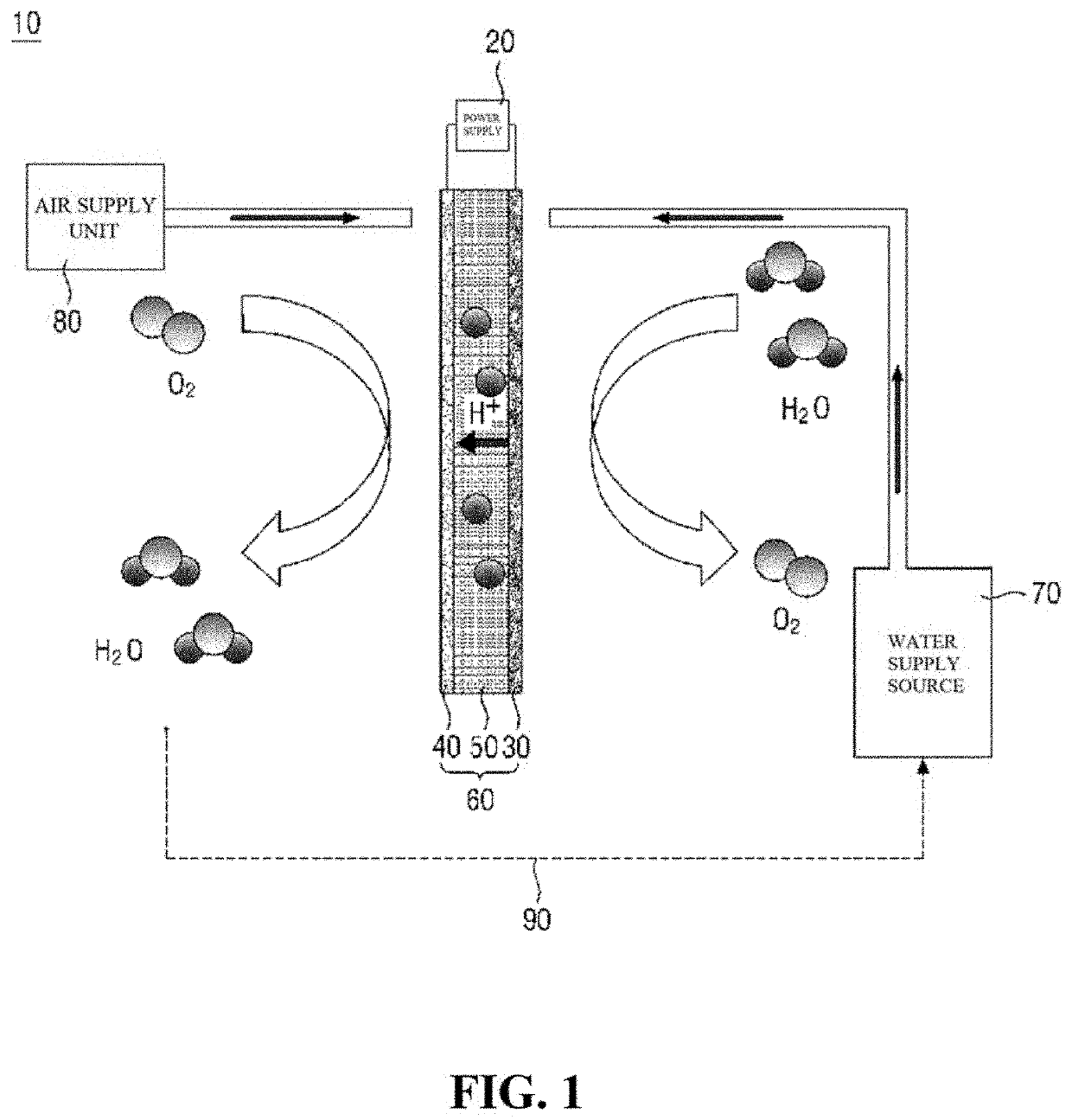

[0116]Water was supplied to the anode through a water supply source, and oxygen was generated from water through an OER. In this case, generated hydrogen ions moved through the nation electrolyte membrane, and an ORR, through which oxygen in air is reduced to generate water, occurred at the cathode.

[0117]FIG. 5 is a graph showing a change in oxygen generation current density according to a voltage of Experimental Example 1.

[0118]In FIG. 5, Pt / C—IrO2 (Air-Water) means that Pt / C was used as a cathode catalyst, IrO2 was used as an anode catalyst, air was supplied to the cathode through a separate air supply unit, and water was supplied to the anode through a separate water supply source. Hereinafter, the expressions have the same meaning.

[0119]Referring to FIG. 5, when a...

experimental example 2

[0120]On a nafion electrolyte membrane, platinum as a catalyst was applied on a cathode, and an iridium oxide catalyst having a nanoporous structure was applied on an anode using a spray method, a decal method, or the like.

[0121]In this case, unit cell evaluation was performed in the same manner as in Experiment Example 1 described above except that the supply of water to the anode through a water supply source was cut off and the supply of air to the cathode through an air supply unit was cut off.

[0122]FIG. 6 is a graph showing a change in oxygen generation current density according to a voltage of Experimental Example 2.

[0123]In FIG. 6, Pt / C—IrO2 (Non Air-Water) means that Pt / C was used as a cathode catalyst, IrO2 was used as an anode catalyst, the supply of water to the anode through the water supply source was cut off, and the supply of air to the cathode through the air supply unit was cut off.

[0124]Referring to FIG. 6, when a voltage of 1.4 V was applied, a current density of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| air flow rate | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com