Titanium base material, method for producing titanium base material, electrode for water electrolysis, and water electrolysis device

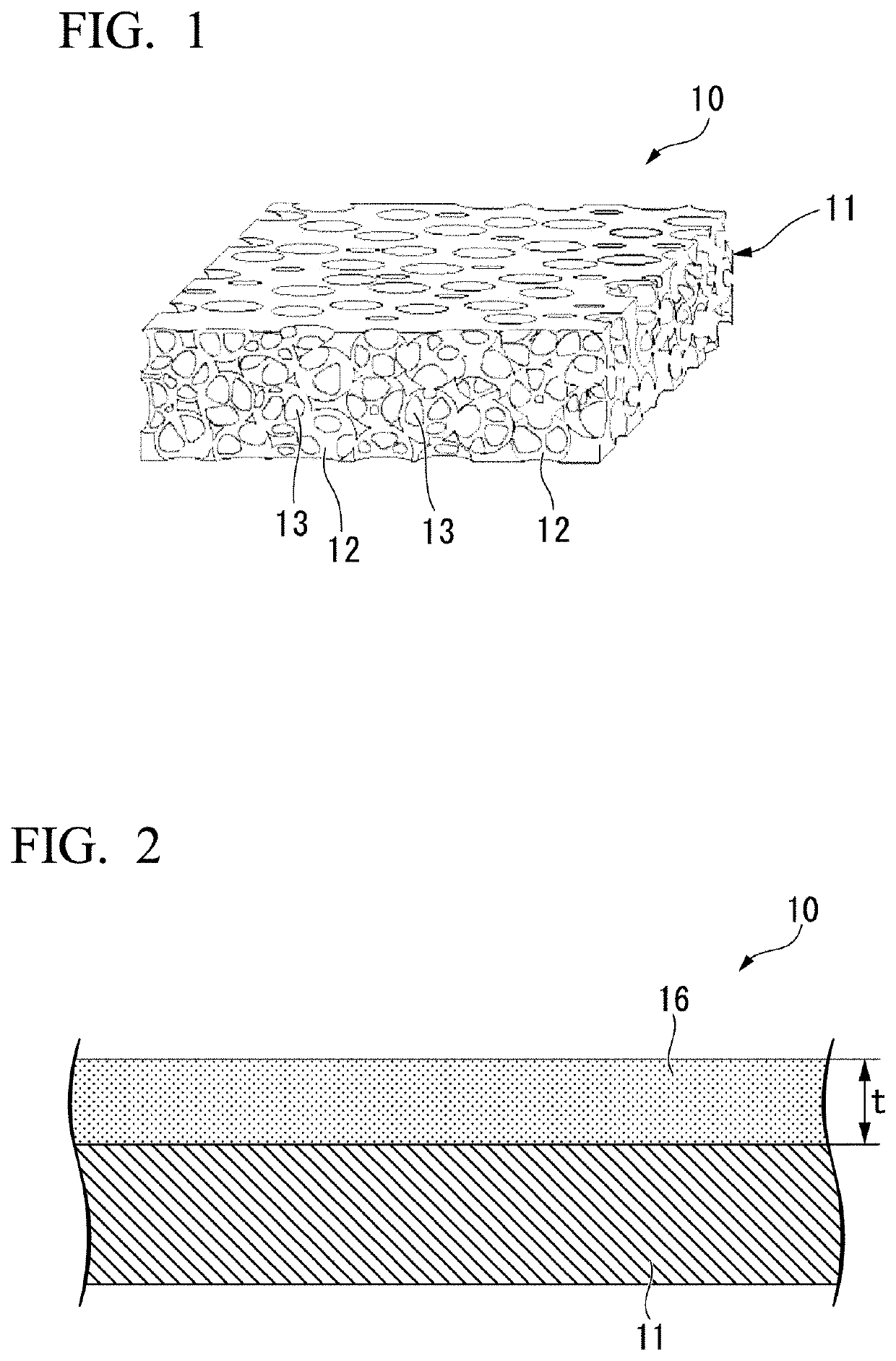

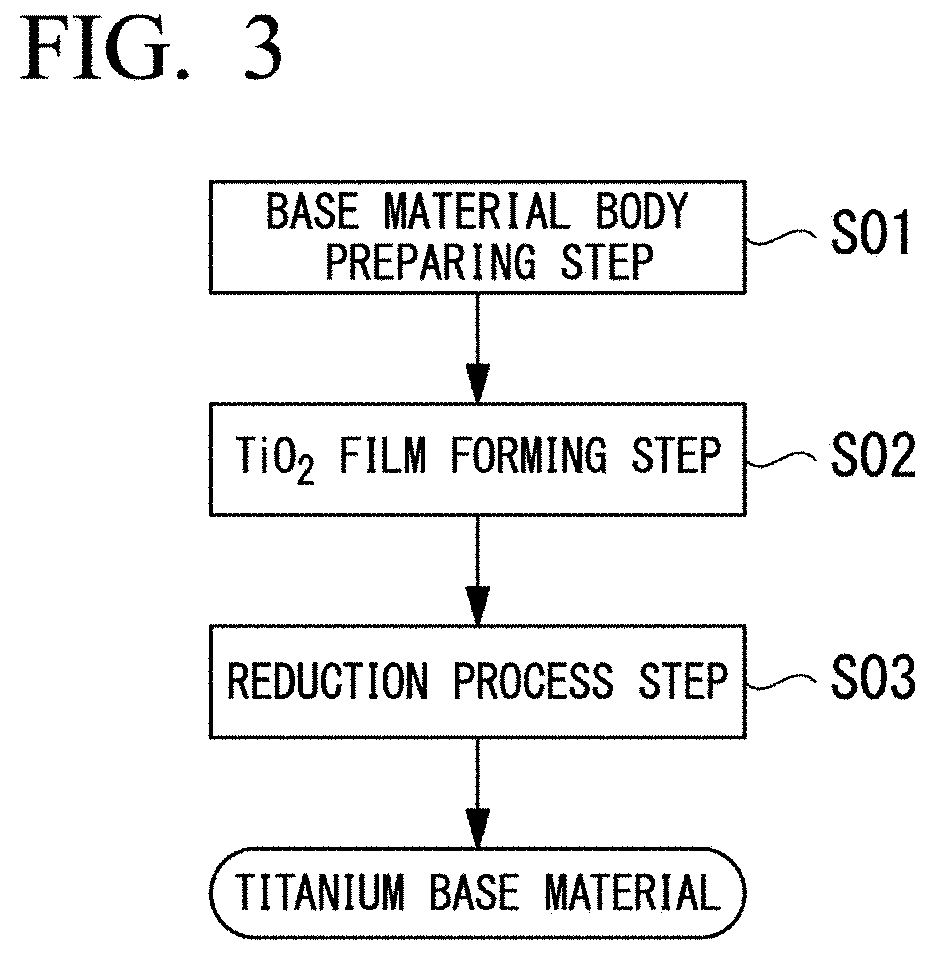

a technology of titanium base material and titanium electrode, which is applied in the direction of electrode coating, cell components, superimposed coating process, etc., can solve the problems of insufficient corrosion resistance and degradation of the performance of current-carrying members such as electrodes, and achieve excellent conductivity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0106]A description will be given below of the results of confirmation experiments performed to confirm the effects of the present invention.

[0107]First, the base material body shown in Table 1 is prepared. In Table 1, “titanium” was pure titanium having a purity of 99.9 mass % or more, and “titanium alloy” was a titanium alloy having Ti-0.15 mass % Pd.

[0108]The dimensions of each prepared base material body were width 50 mm×length 60 mm×thickness 0.3 mm.

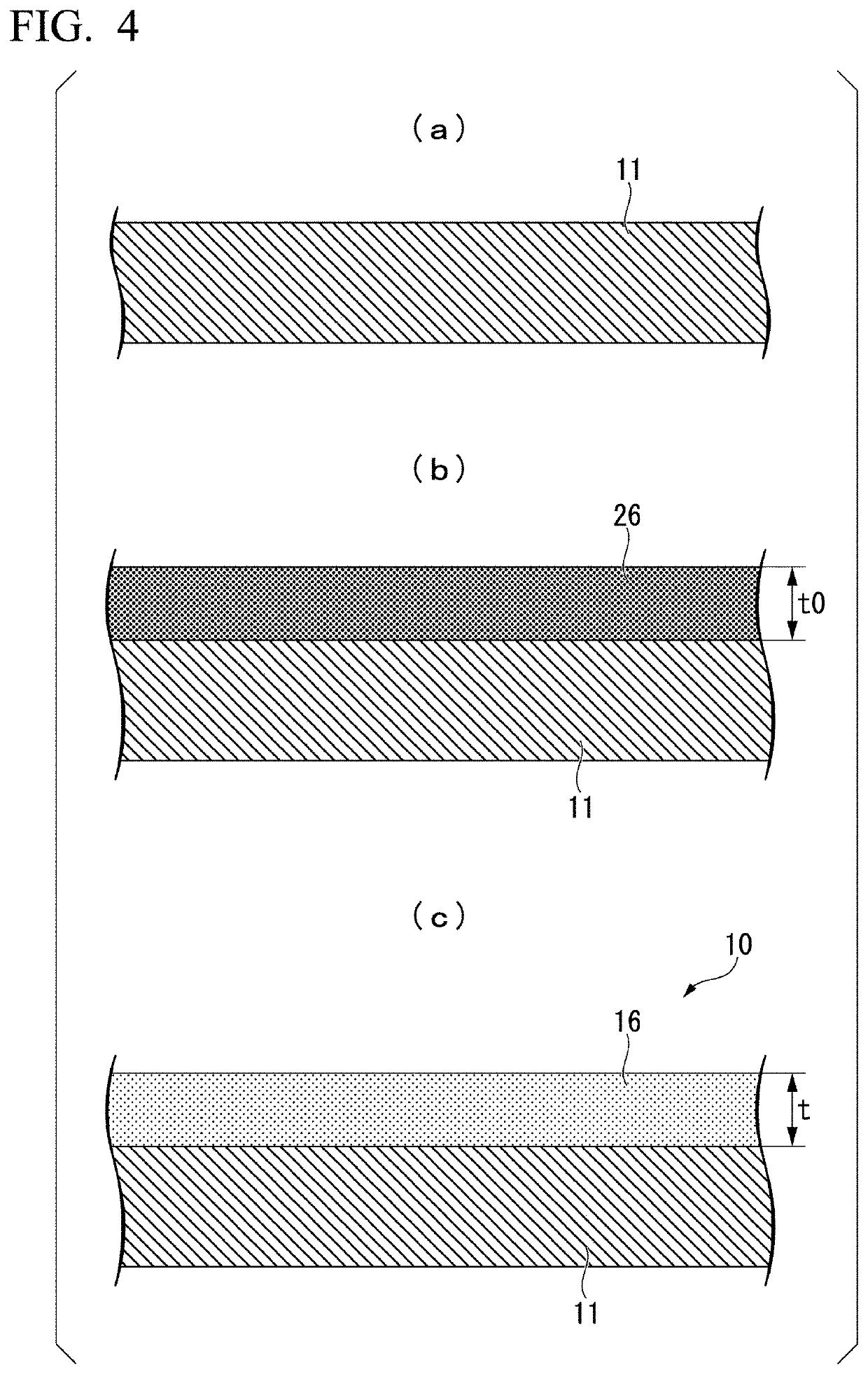

[0109]Next, a TiO2 film is formed on the surface of the base material body. A plasma electrolytic oxidation process was carried out in an aqueous solution of K3PO4. A high-density carbon plate was used as the cathode and the above was carried out under conditions of a temperature of 100° C. or lower, a voltage of 450 V, and a time of 0 to 300 minutes. The film thickness of the TiO2 film was set to the value shown in Table 1 by adjusting the time of the plasma electrolytic oxidation process.

[0110]Next, the base material body on which...

example 2

[0126]Next, as shown in Table 3, a titanium base material (Invention Example 11) on which a Magneli phase titanium oxide film was formed and a titanium base material (Comparative Example 7) on which a titanium oxide film (insulating titanium oxide film) which was not a Magneli phase titanium oxide film was formed were each used as an anode electrode, a solid polymer water electrolysis cell (area 4 cm×4 cm) having the structure shown in FIG. 5 was formed and set as Invention Example 101 and Comparative Example 101.

[0127]In Comparative Example 102, a titanium base material on which a titanium oxide film was not formed on the surface of the base material body formed of a porous body was used as the anode electrode.

[0128]For this water electrolysis cell, a voltammetry test was carried out at 2.5 V for 1 minute and 0 V for 1 minute as one cycle. The current density flowing in the cell due to water electrolysis was measured. The test temperature was 80° C. The evaluation results are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com