Laser welding boiler tube wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

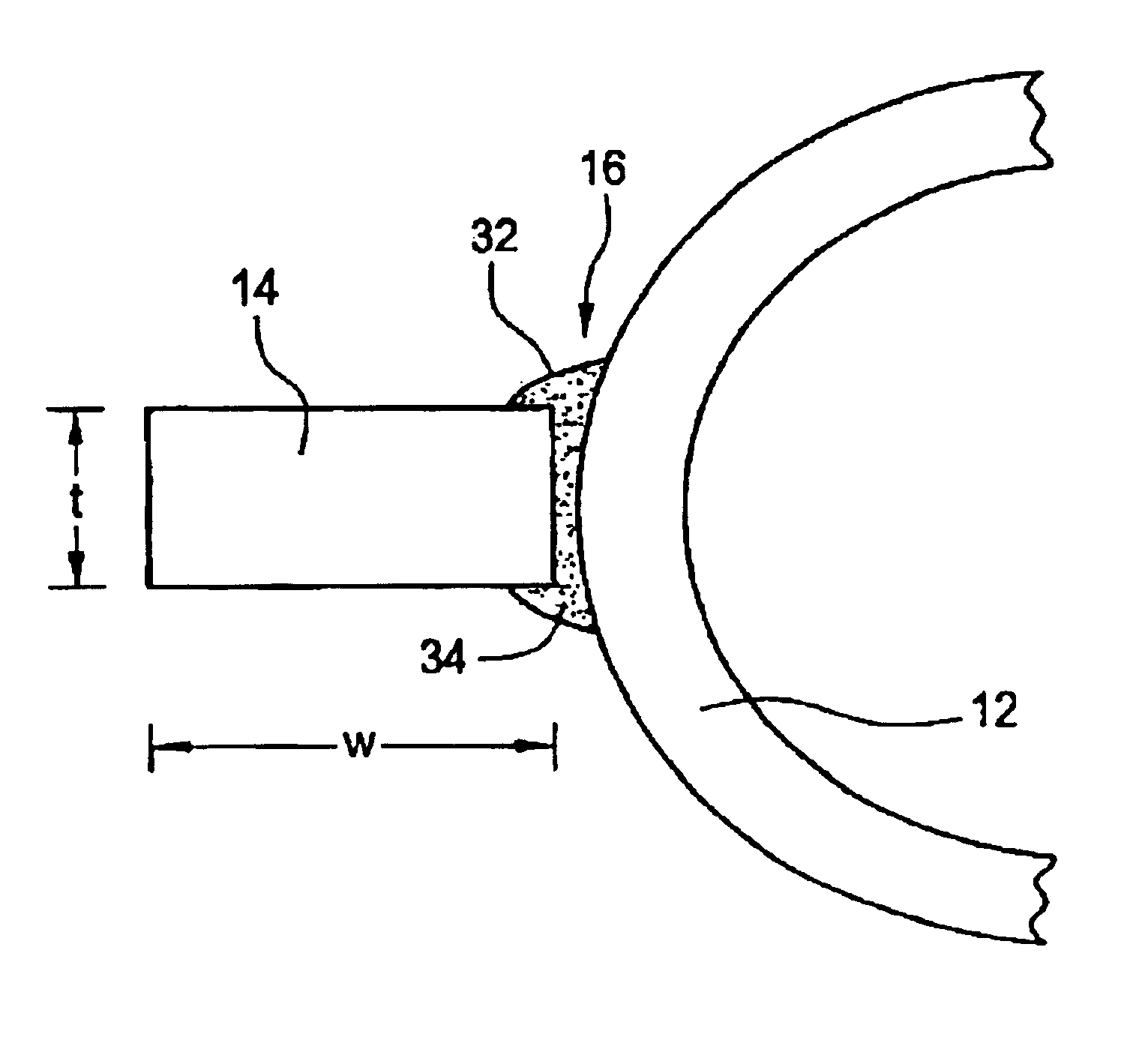

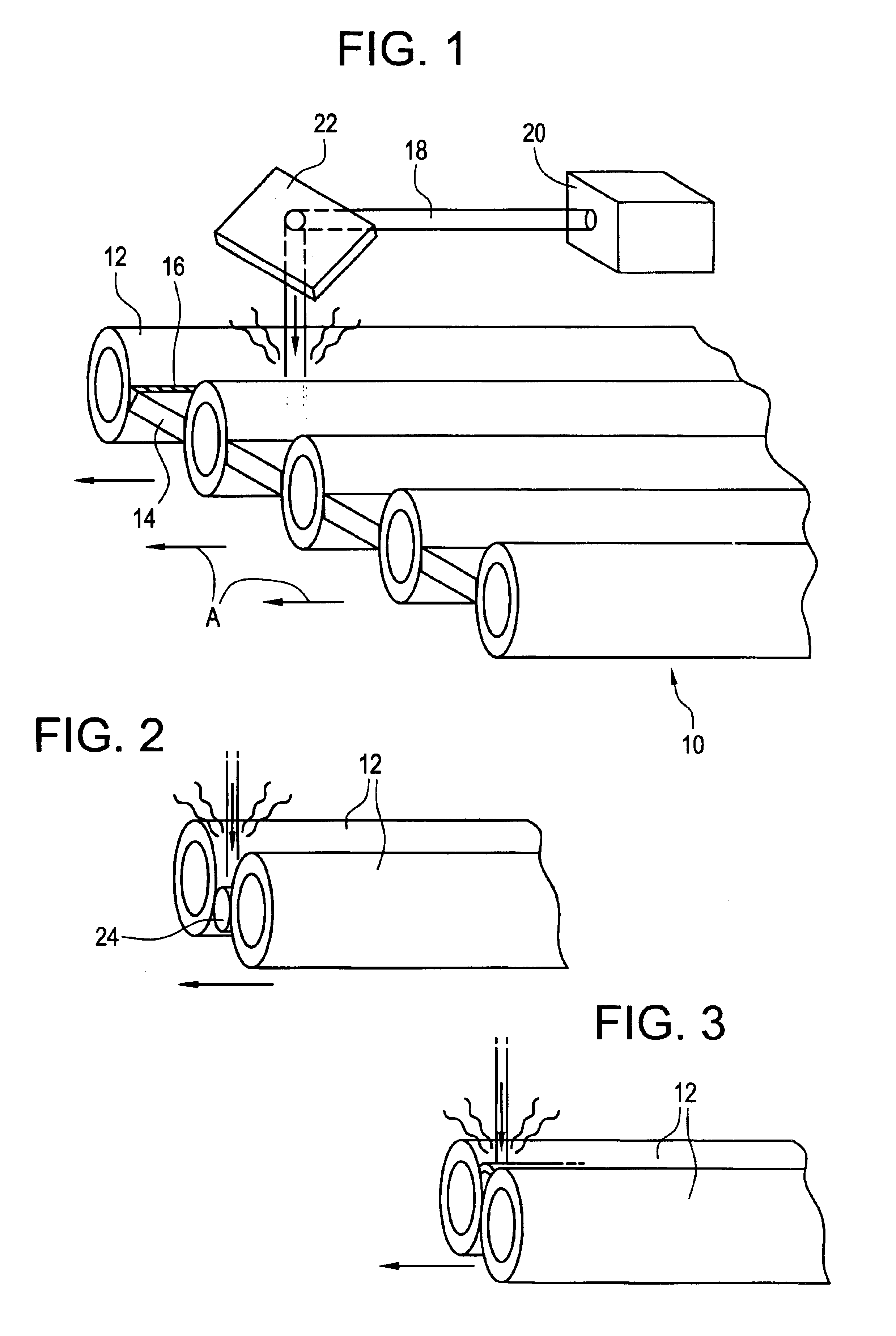

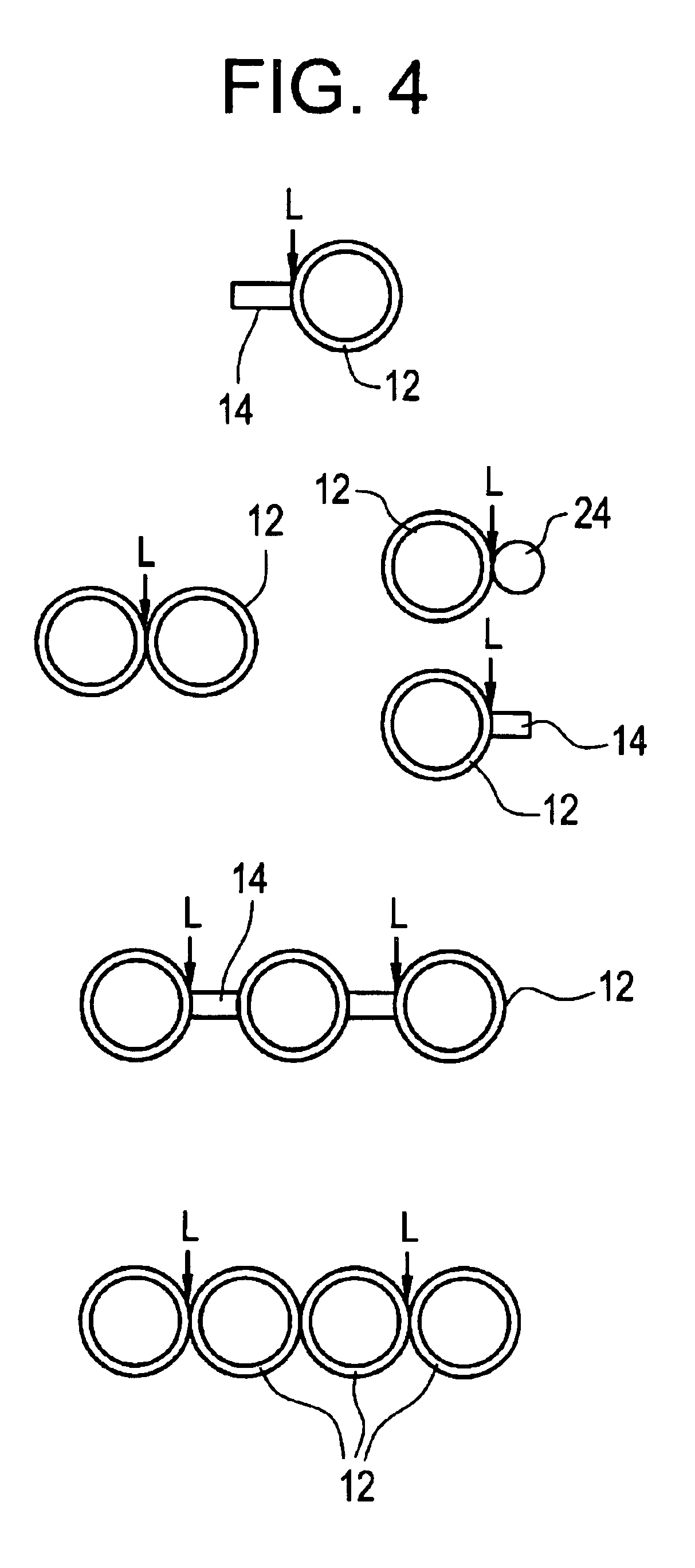

FIG. 5 shows a preferred setup of the invention for the invention in which a laser beam 18 is used to form the weld line 16. According to this embodiment, laser beam 18 is advantageously directed toward the weld line 16 inclined at a laser beam angle 2, measured from a line L1 perpendicular to a plane of the panel and in a plane perpendicular to the weld line 16, within the range of about 2 to 15 degrees, and preferably about 5 to 10 degrees.

In a laboratory test of the above laser-only embodiment membrane plate 14 was successfully welded along weld line 16 to a tube 12 solely from one side of the membrane plate 14, using the following process parameters:

laser travel speed:about 35 inches per minutelaser power:5.5 kW

Laser beam 18 was directed toward the welding point P at a laser beam angle 2 of about 5 degrees. The tube 12 used in the test was a carbon steel tube having an outer diameter of 1.5 inches and a wall thickness of 0.203 inches. The membrane plate 14 was made of A36 steel ...

second embodiment

FIG. 7 shows a preferred setup of the invention for a second embodiment that combines a known GMAW welding head 26 with the laser beam 18 to form the weld line 16. For a fixed laser power, the addition of GMAW welding head 26 makes the method of the present invention more reliable in a production environment.

In the laser-plus-GMAW embodiment laser beam 18 is advantageously directed toward the weld line 16 inclined at the laser beam angle 2, as shown in FIG. 7, within the range of about 2 to 15 degrees, and preferably about 5 to 10 degrees, and the GMA welding axis is directed toward the weld line 16 at a torch angle 4 of about 5 degrees measured from a plane PL perpendicular to the plane of the panel and containing the weld line 16, also as shown in FIG. 7 (or within the range of about 2 to 15 degrees). Further the GMA welding axis is applied at a lead angle 6 relative to the travel direction A within the range of about 10 to 50 degrees or preferably about 20 to 40 degrees.

For purpo...

third embodiment

FIG. 8 illustrates a preferred arrangement of the invention in which the membrane plate 14 is modified to include a bevel 30 along the edge adjacent weld line 16. The beveled membrane plate 14′ is beveled at a bevel angle b to a depth d.

In a laboratory test of the laser-plus-GMAW embodiment with a beveled membrane plate 14″, the beveled membrane plate 14′ was successfully welded along weld line 16 to a tube 12 solely from one side of the membrane, using the following process parameters:

laser and GMAW travel speed:about 31 inches per minutelaser power: 5 kWGMAW shield gas:100% heliumGMAW wire:0.035″ dia. ER70S-3GMAW wire feed speed:about 100 inches per minuteGMAW voltage:about 25 voltsGMAW peak current:100 ampsGMAW background current: 30 amps

GMAW welding head 26 was directed toward the welding point P at a torch angle 4 of about 5 degrees and a lead angle 6 of about 32 degrees. Laser beam 18 was directed toward the welding point P at a laser beam angle 2 of about 5 to 10 degrees. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com