Device and method for ferrofluid power generator and cooling system

a technology of which is applied in the field of devices and methods for ferrofluid power generator and cooling system, can solve the problems of increasing weight, consuming extra power, and always cooling, and achieves the effects of high spinning speed, high efficiency, and removal of waste hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The device for ferrofluid power generator and cooling system of the preferable embodiments according to the invention is described thereinafter, but its actual layout does not have to completely match the description of the system design. Those who are familiar with such technique may have variations or modifications within the spirit and scope of the invention.

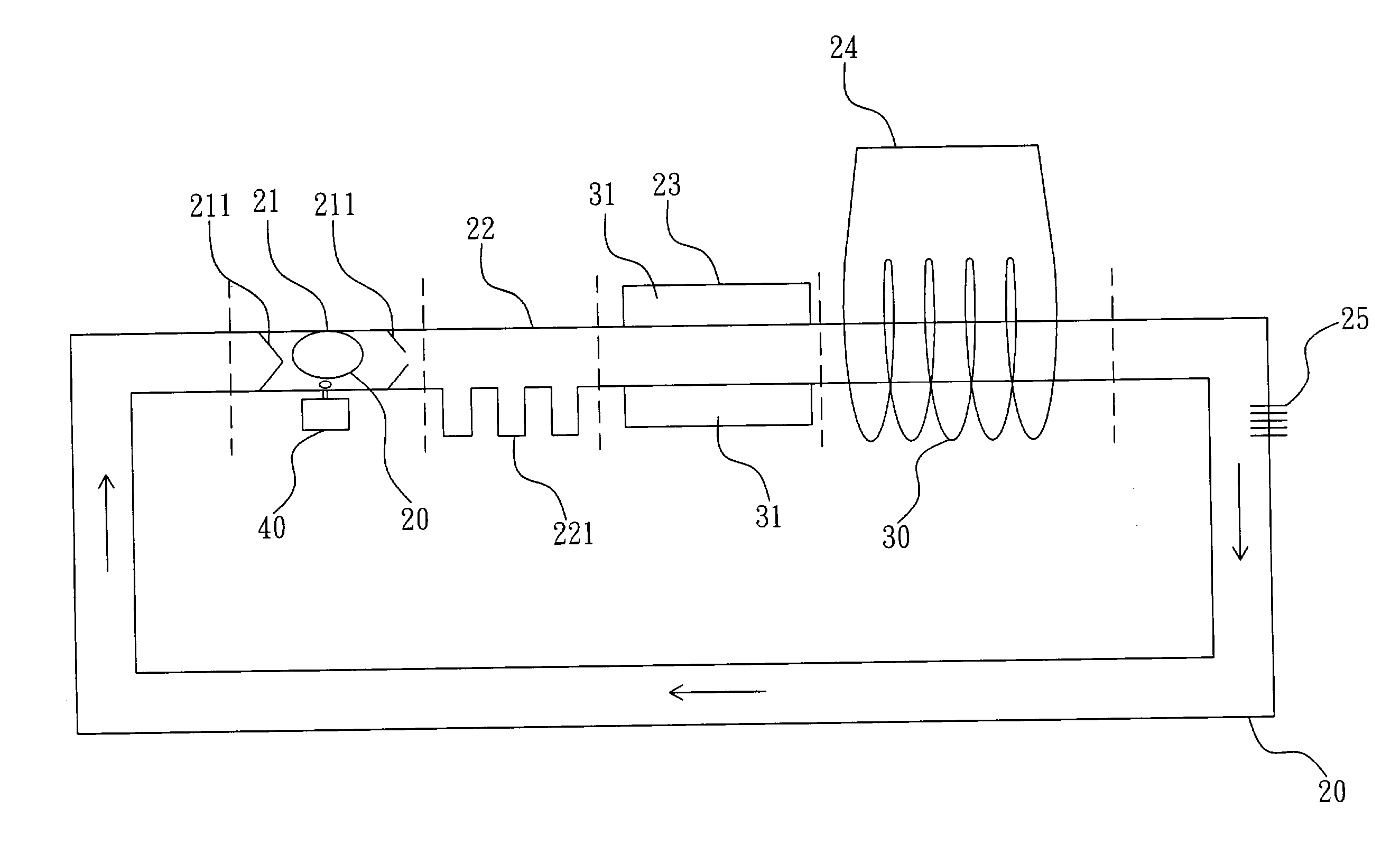

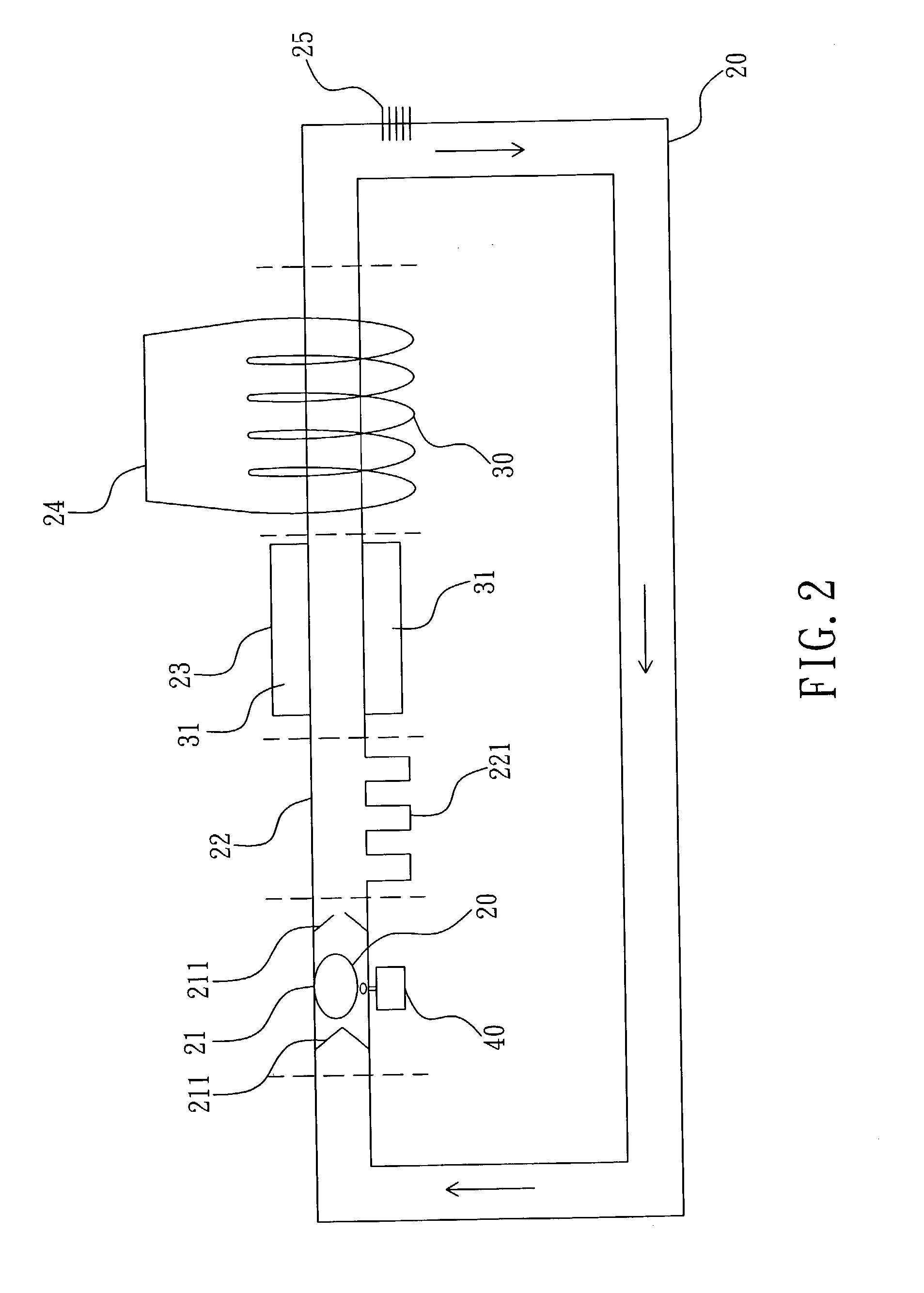

[0028]FIG. 2 is an illustration of the preferable basic layout of a device for ferrofluid power generator and cooling system according to the invention. THE invention includes a pipe system 20 and a coil 30. The pipe system 20 is connected to an electronic device 40 (a central processing unit abbreviated as CPU is taken as an example hereinafter) that generates waste heat. The coil 30 is wound around part of the pipe system 20 which is a closed loop filled with low boiling-point fluid (not shown in the drawings), and the magnetic particles (not shown in the drawings) are again contained in the fluid. When the heat is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com