Semiconductor device

a technology of semiconductor devices and shielding films, applied in semiconductor devices, semiconductor/solid-state device details, electrical devices, etc., can solve the problems of low film density weak cu wiring, and noticeable signal transmission delay disadvantages, etc., to achieve enhanced adhesiveness of diffusion prevention insulation films and conductive layers, the effect of reducing the capacity of the signal transmission delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

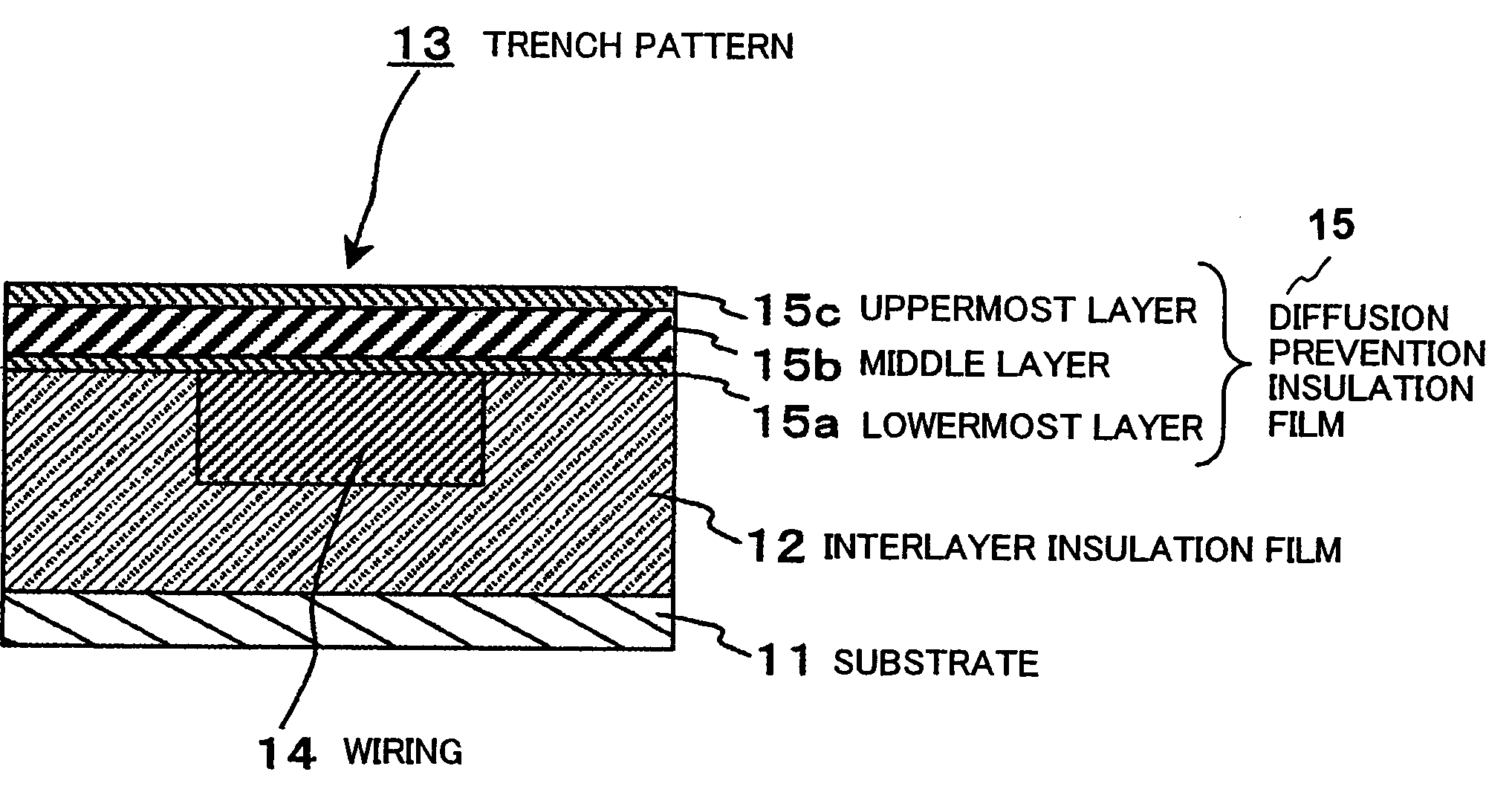

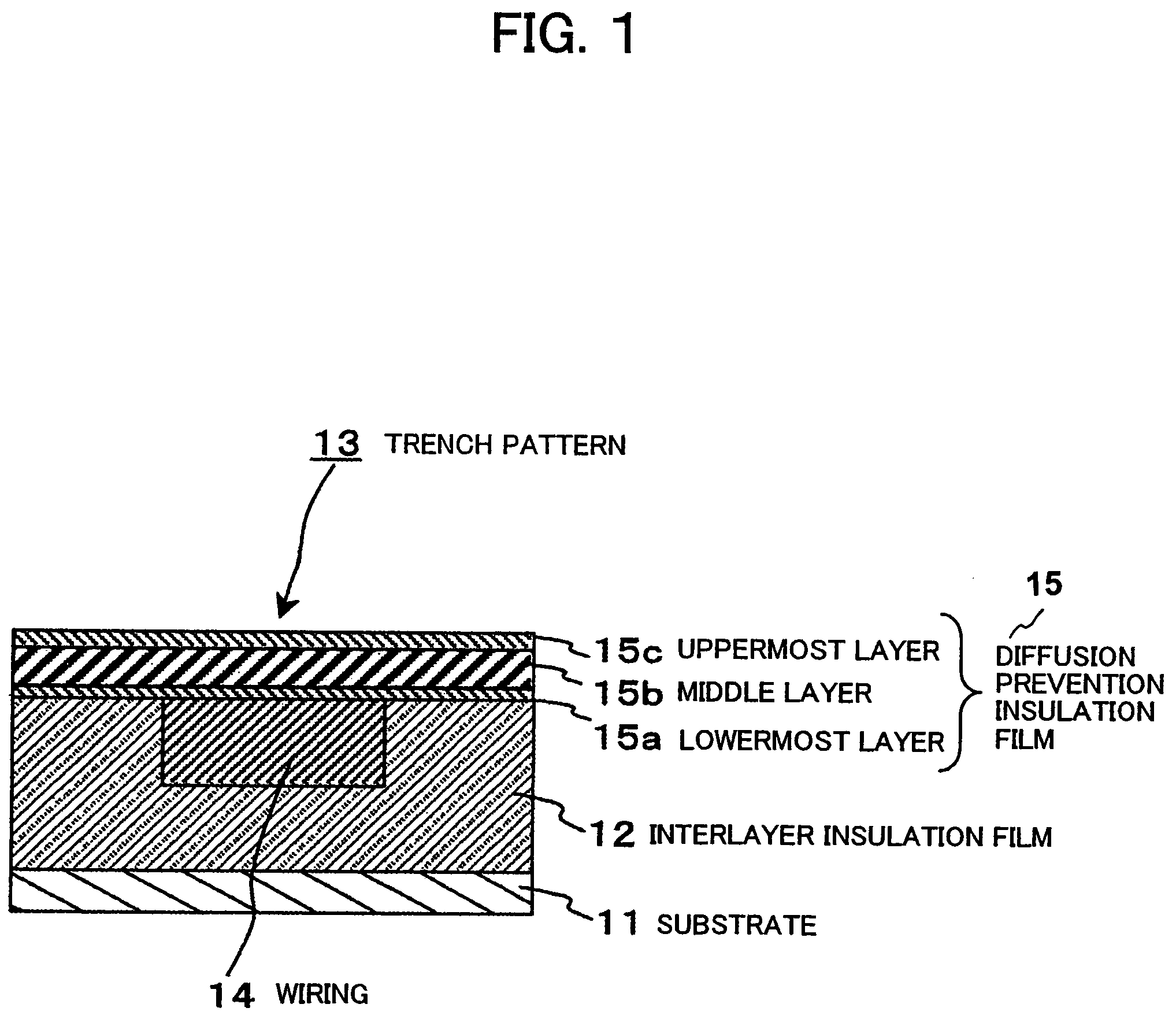

[0047]In the present example, an effect of preventing water permeation of the uppermost layer 15c in the diffusion prevention insulation film 15 of the semiconductor device explained in the embodiment shown in FIG. 1 was tested.

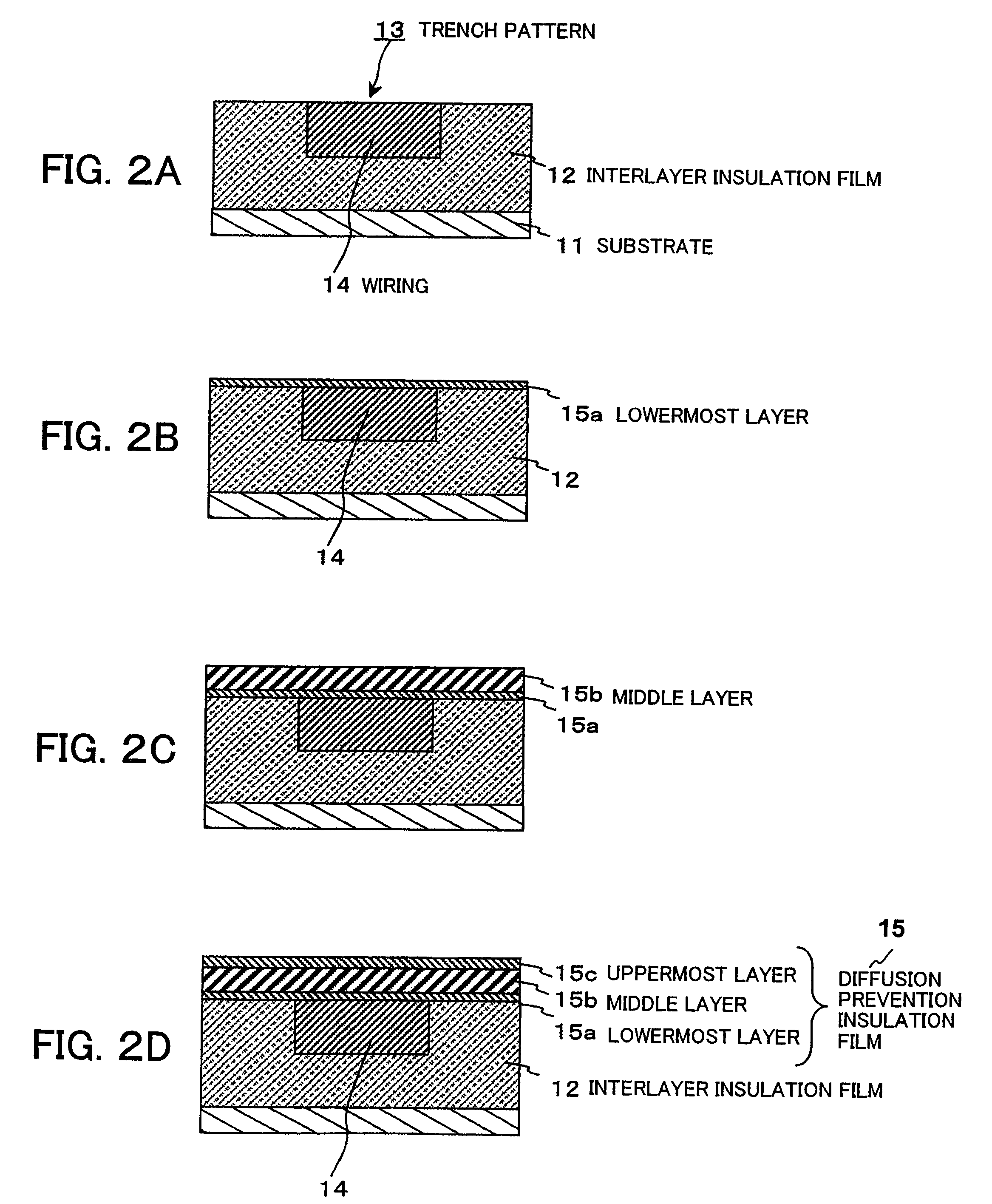

[0048]First, after forming a highly hygroscopic tetraethoxy silane (TEOS) film on a silicon (Si) substrate, a SiC film with low film density having a relative dielectric constant of 3.5 was formed on the TEOS film. The SiC film corresponds to the middle layer 15b in the diffusion prevention insulation film 15 of the present embodiment. After that, a SiCN film with high film density having a relative dielectric constant of 4.9 was formed to be a thickness of 5 nm on the SiC film. The SiCN film corresponds to the uppermost layer 15c in the diffusion prevention insulation film 15 of the present embodiment. The result was called a sample 1. On the other hand, what obtained by forming a TEOS film on a Si substrate, then, forming a SiC film having a relative dielec...

example 2

[0052]In the present example, the EM resistance of the diffusion prevention insulation film 15 in the semiconductor device explained in the embodiment was tested.

[0053]First, as shown in FIG. 1, a diffusion prevention insulation film 15 having the same configuration as that in the embodiment was formed in the same wiring structure as that in the embodiment. Specifically, the lowermost layer 15a and the uppermost layer 15c in the diffusion prevention insulation film 15 were SiCN films having a thickness of 5 nm, a relative dielectric constant of 4.9 and high film density, and the middle layer 15b was a SiC film with low film density having a relative dielectric constant of 3.5. The result is called a sample “A”. Also, what using a SiC film having a relative dielectric constant of 3.5 corresponding to the middle layer 15b of the present embodiment as a diffusion prevention insulation film 15 is called a sample “B”, and what using a SiC film having a relative dielectric constant of 3.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com