Catadioptric projection system for 157 nm lithography

a projection system and catadioptric technology, applied in the direction of instruments, lighting and heating equipment, photomechanical equipment, etc., can solve the problems of low numerical aperture, difficult mounting and adjustment face, and similar mounting and adjustment difficulties, so as to simplify the design of stressed qualities and more degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

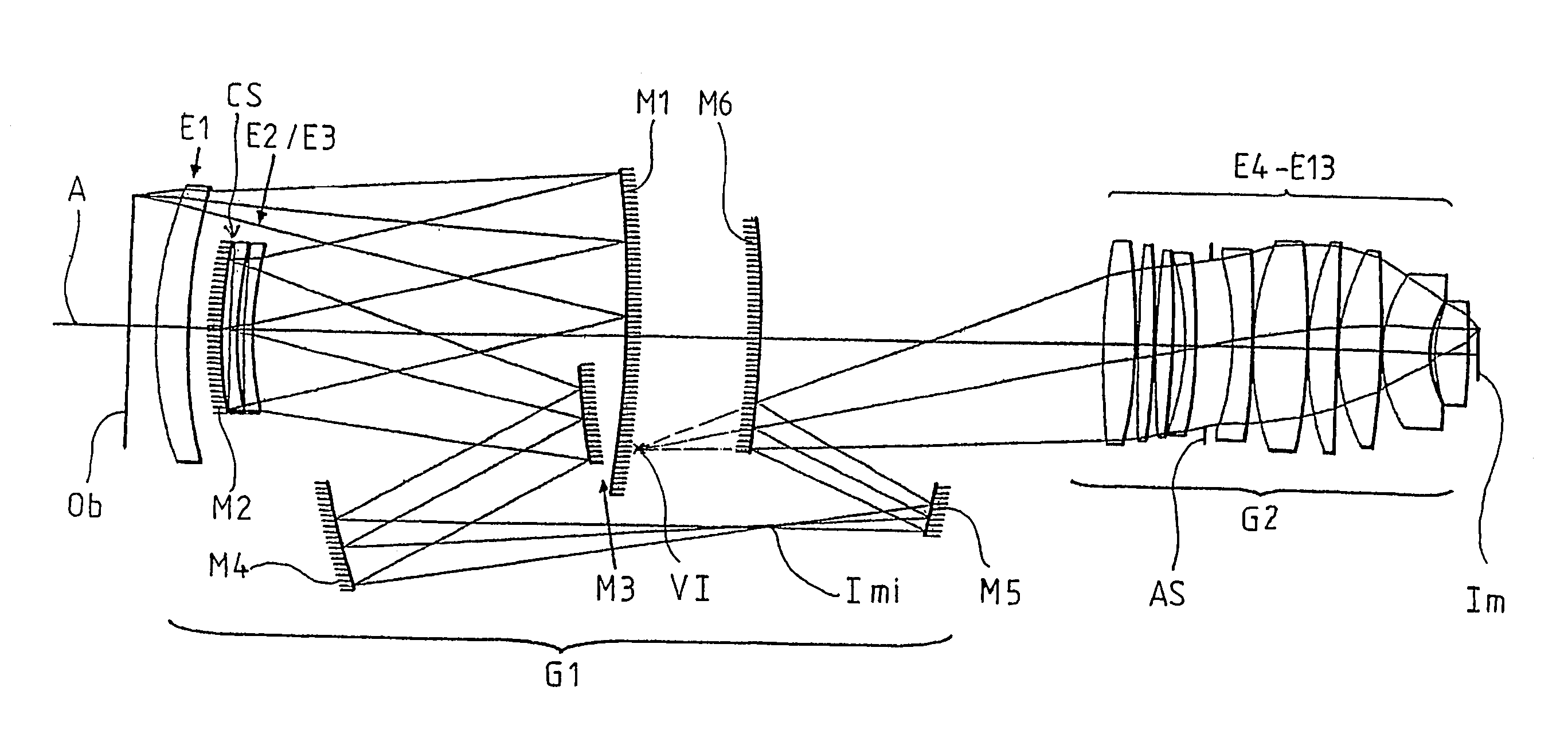

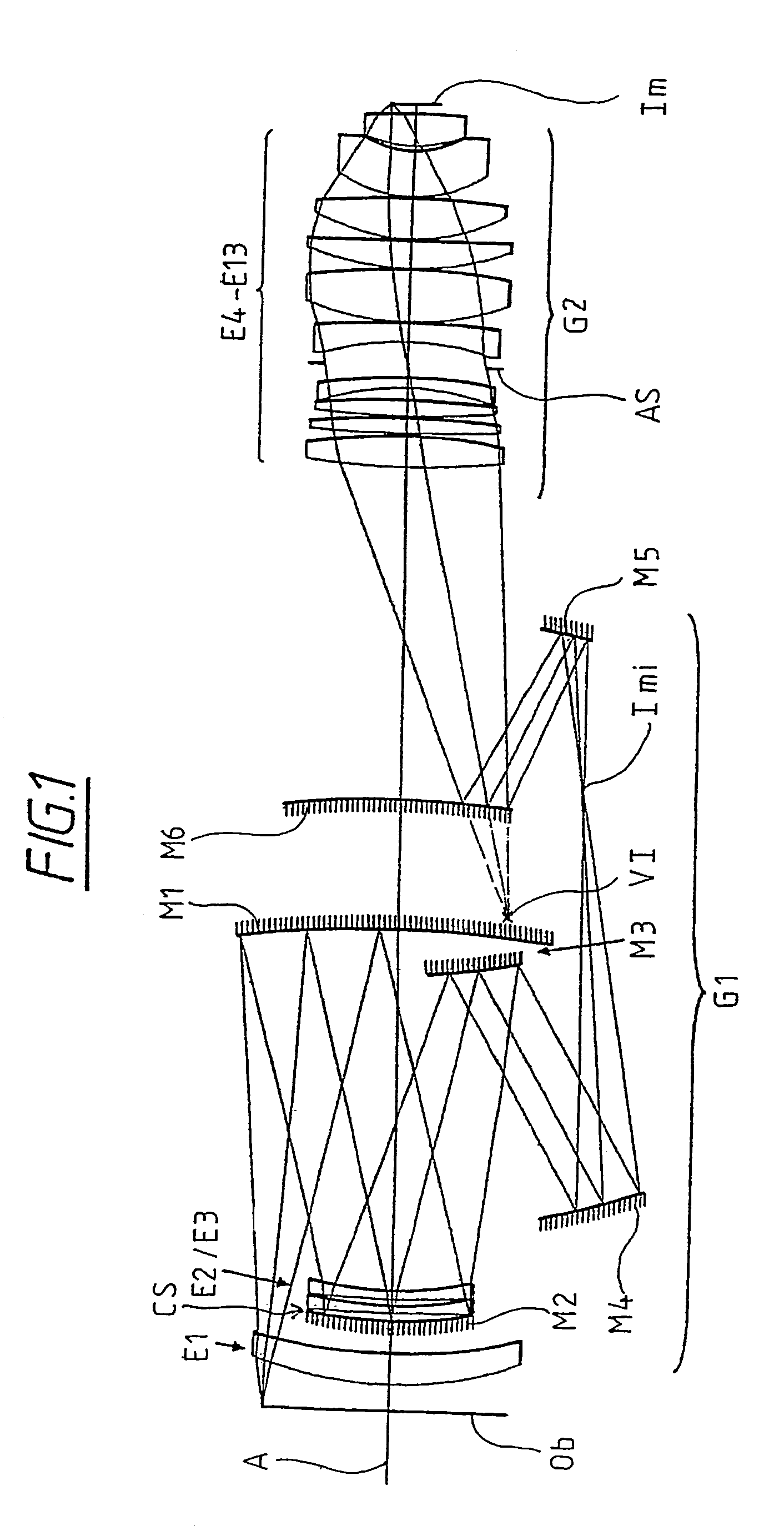

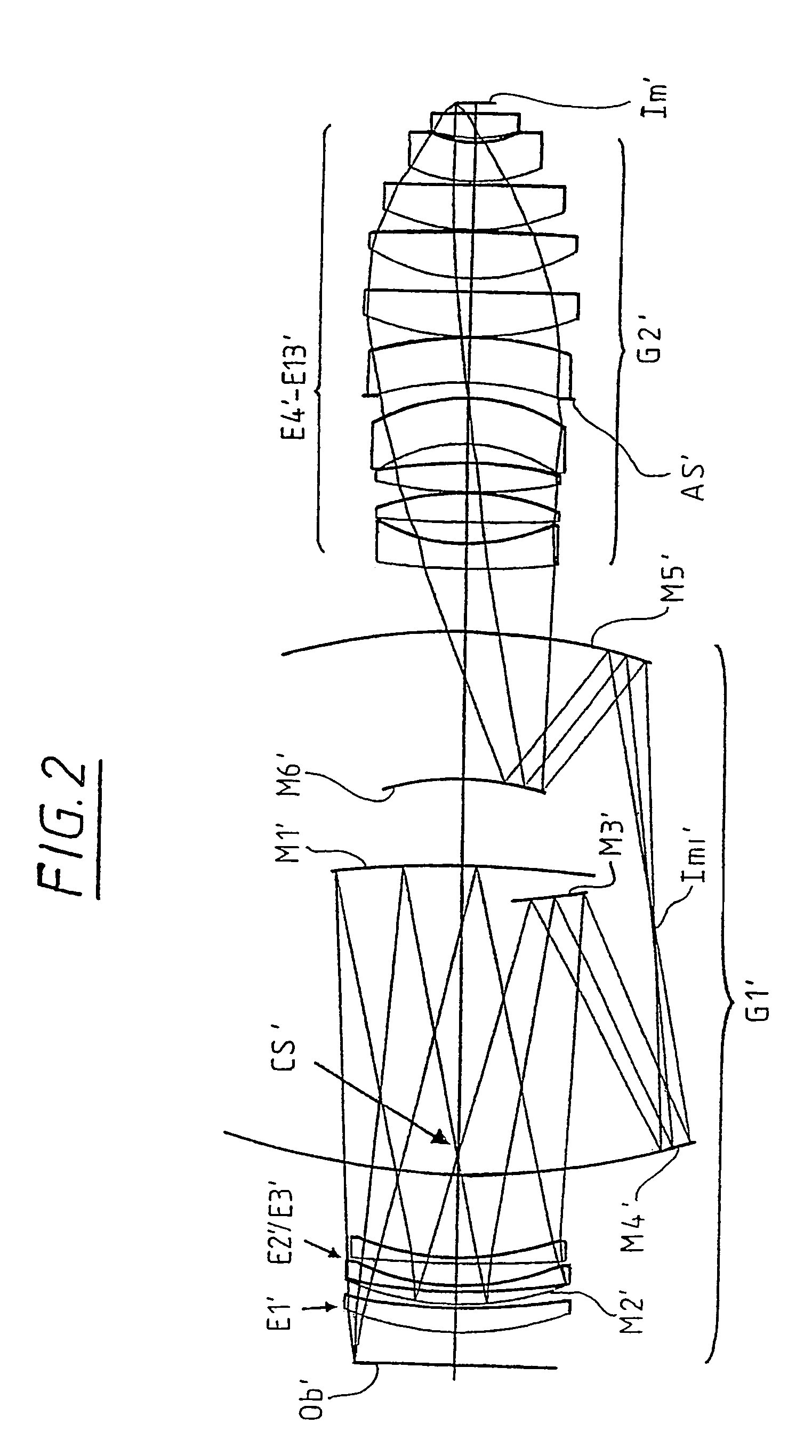

[0026]A catadioptric projection system according to a preferred embodiment herein is schematically shown at FIG. 1 and includes two distinct optical groups G1 and G2. Group G1 is a catadioptric group including mirrors M1–M6 and lenses E1–E3, as shown in FIG. 1. An object or mask plane Ob is disposed to the left of group G1 in FIG. 1 or optically before group G1. Group G2 is disposed optically after group G1 and to the right of group G1 in FIG. 1. An image or wafer plane Im is disposed optically after group G2 and to the right of group G2 in FIG. 1.

[0027]Group G1 functions by correcting field aberrations and providing a conjugate stop position for correction of axial chromatic aberration. Group G2 is a dioptric group including lens elements E4–E13, as also shown in FIG. 1. Group G2 lies aft of G1, or optically nearer the image plane of the system, enabling the system to achieve numerical apertures in excess of 0.65, 0.70 and even 0.75. This catadioptric system achieves a high numeric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com