High durable, low-e, heat treatable layer coating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

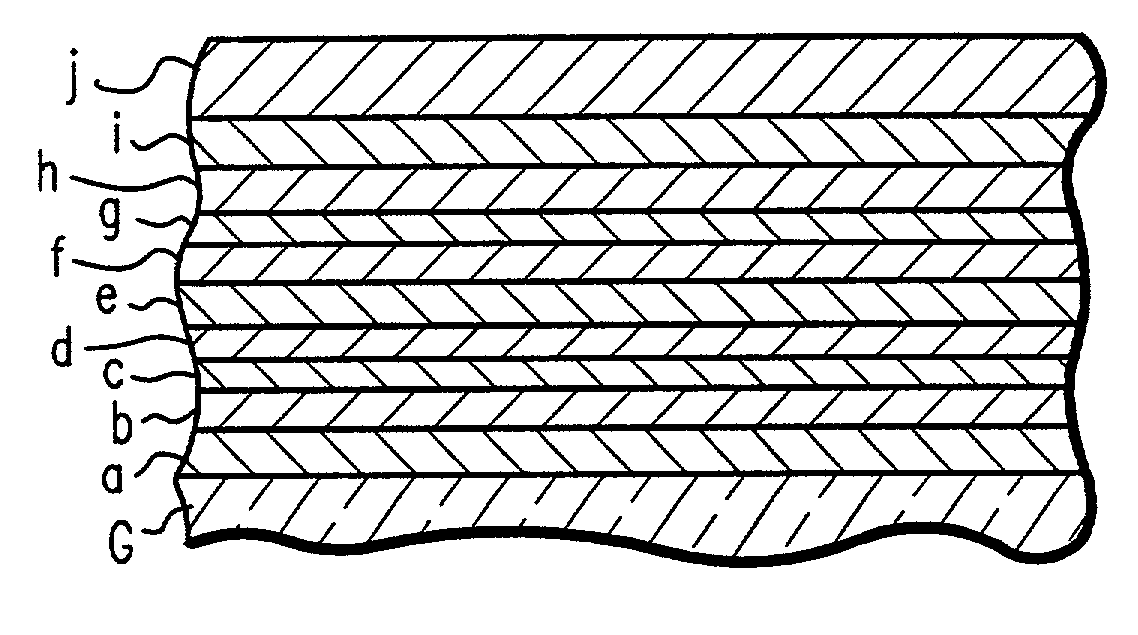

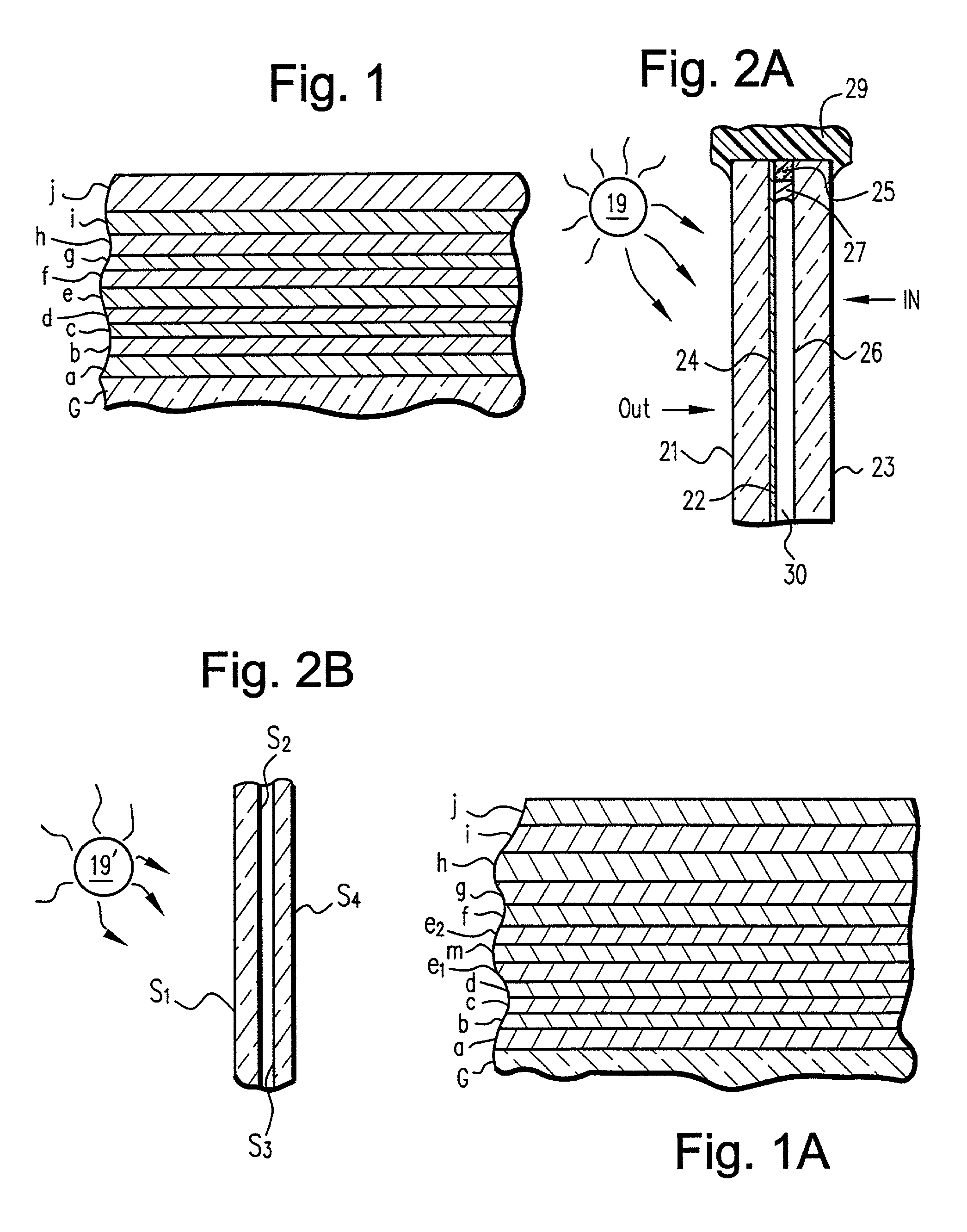

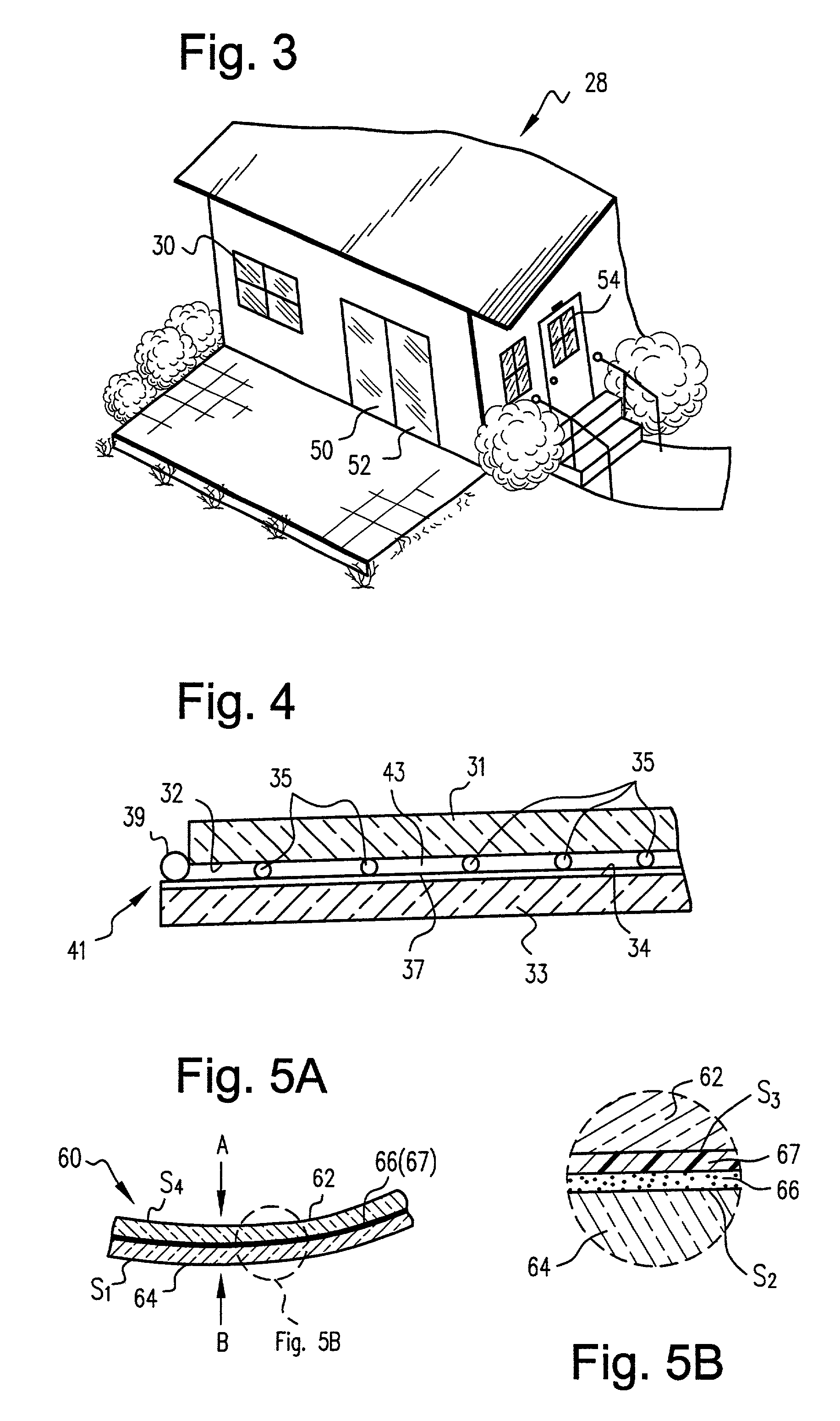

[0073]Using an Airco ILS-1600 research coater the following layer system (with reference to FIG. 1) was sputter coated onto various 3 mm thick, clear float glass samples of about 3″×3″ to be tested as reported hereinafter.

[0074]

TABLE IIILayerThicknessSpeedPowerArgonOxygenNitrogenPressureLayerMaterial1AngstromsInches / minPassesVoltskWAmperagesccmsccmsccmmTorraSnOx408A4244741.002.1404003.1bTiOx 25A4524850.906.5451001.7cAg100A10015200.791.5350001.4dNiCrOx 28A10014630.604.4405.501.5eSnOx1816A4284741.002.1404003.1fTiOx 25A4524850.906.5451001.7gAg110A10015250.871.6650001.4hNiCrOx 28A10014630.604.4405.501.5iSnOx260A5034741.002.1404003.1jSi3N4185A77.545100.901.77500251.8

A glass substrate sample so formed (e.g. approx. 3″×3″ of clear float glass) was then heat treated by heating it to 630° C. for ten minutes and air cooling it to room temperature. In another test sample, a coated sheet (3″×3″) and an uncoated sheet were laminated together to simulate an automotive windshield such as that show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com