Current and aeration system for wastewater plant

a wastewater plant and aeration system technology, applied in the direction of multi-stage water/sewage treatment, other chemical processes, separation processes, etc., can solve the problems of deterioration of the wastewater treatment process, sludge disposal presents an ecological problem, and failure of air flow in the aeration chamber, so as to minimize the formation and accumulation of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

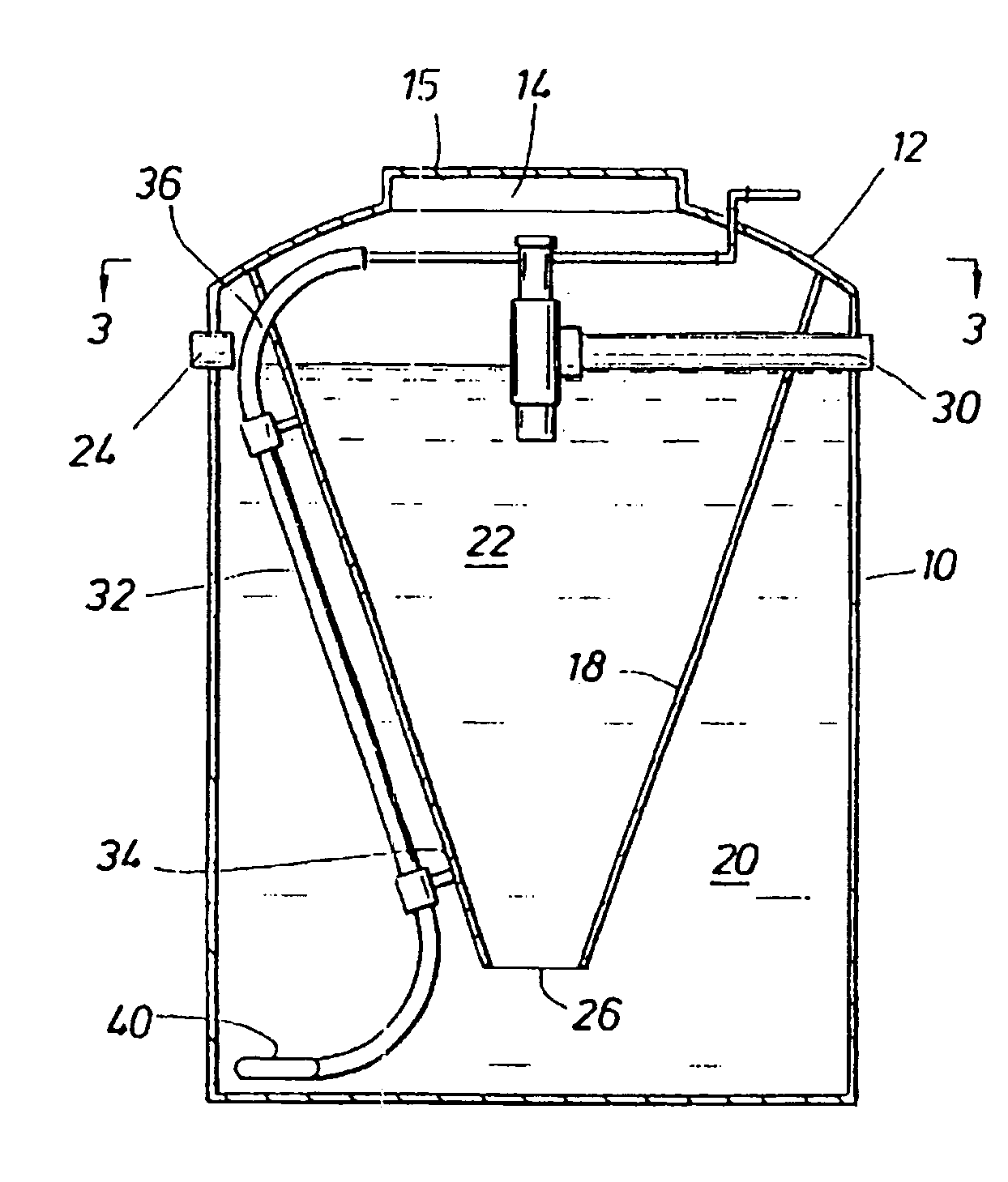

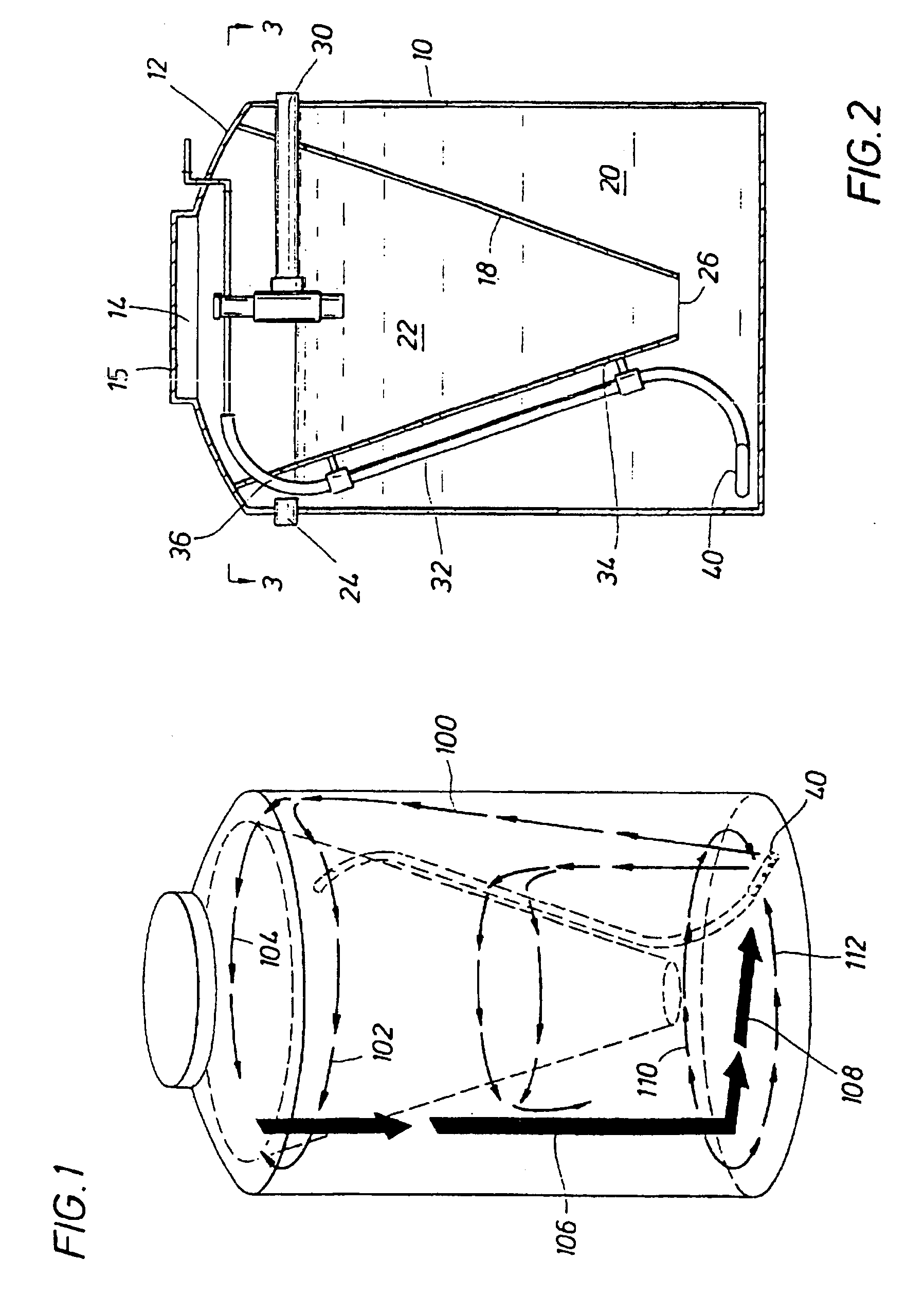

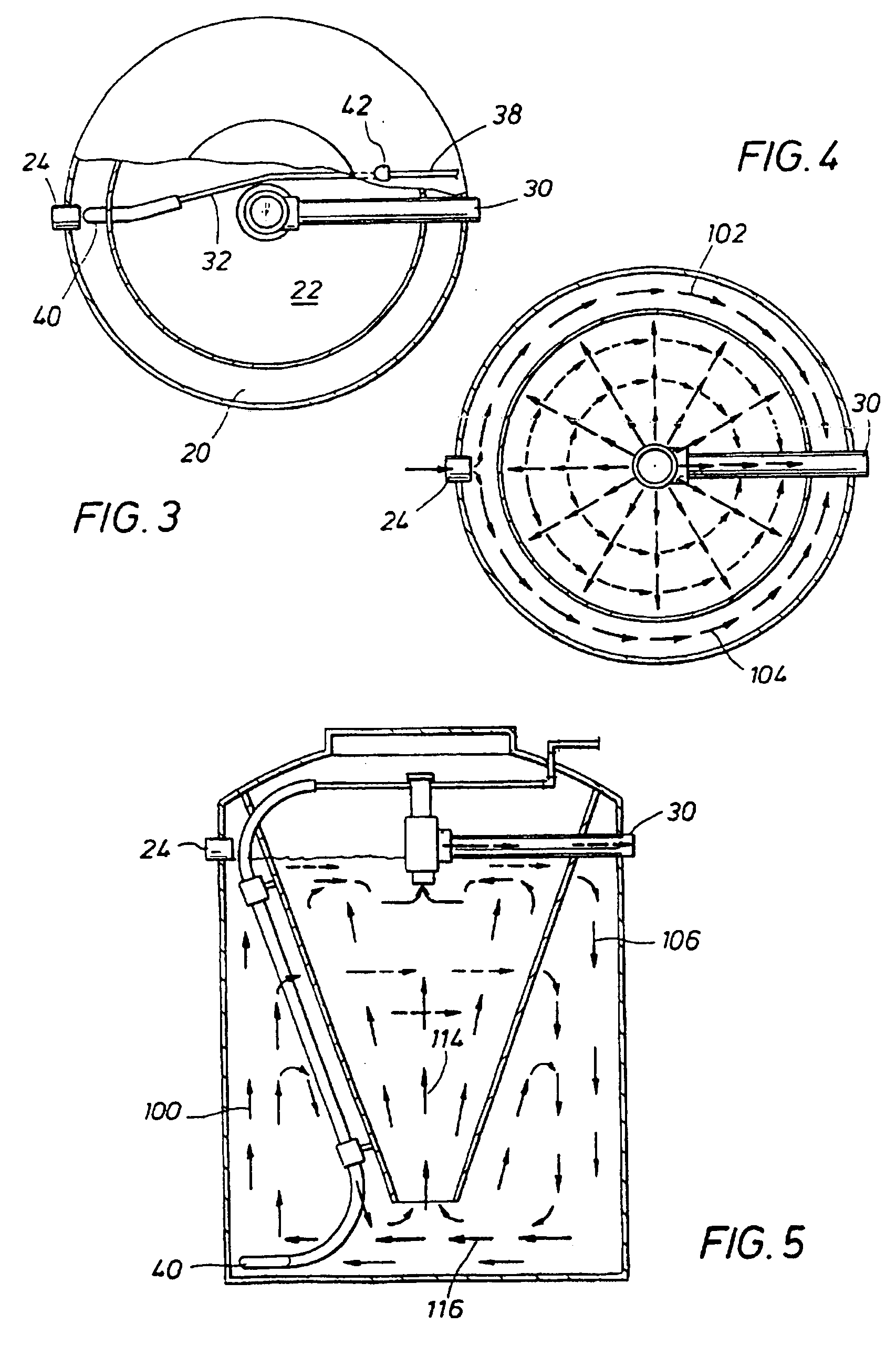

[0028]The water treatment plant of a preferred embodiment shown in the drawings includes cylindrical tank 10 with dome-shaped upper end 12. Opening 14 is located in the upper end to provide access to the inside of the tank. Usually, the tank is buried in the ground so that only opening 14 and its cover 15 are above ground.

[0029]Inside the tank is partition 18 that is shaped like an inverted, truncated, cone. The upper end of the partition is attached to dome-shaped upper end 12. This partition divides the tank into two chambers, aeration chamber 20 and clarifier chamber 22.

[0030]In operation, wastewater from the residence or facility to which the plant is connected enters the aeration chamber through inlet 24. Flow through the plant is a result of hydrostatic pressure. The water entering inlet 24 will increase the hydrostatic head in aeration chamber 20 causing water to flow into opening 26 in the bottom of the clarifier chamber. This causes the water in the clarifier chamber to mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| rate of reduction | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com