Sterilization by low energy electron beam

a low-energy electron beam and sterilization technology, applied in the field of sterilization, can solve the problem of limited effect rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

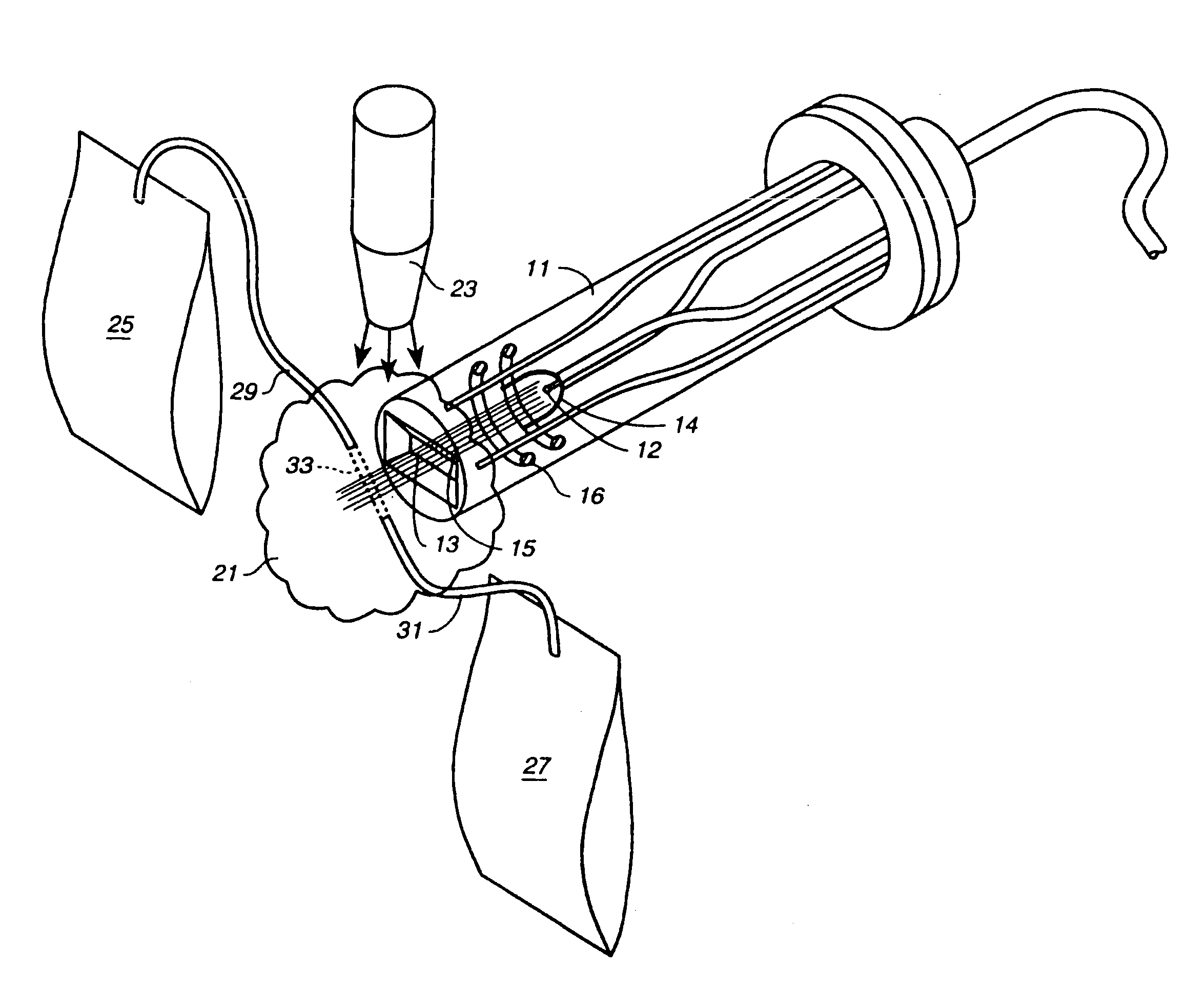

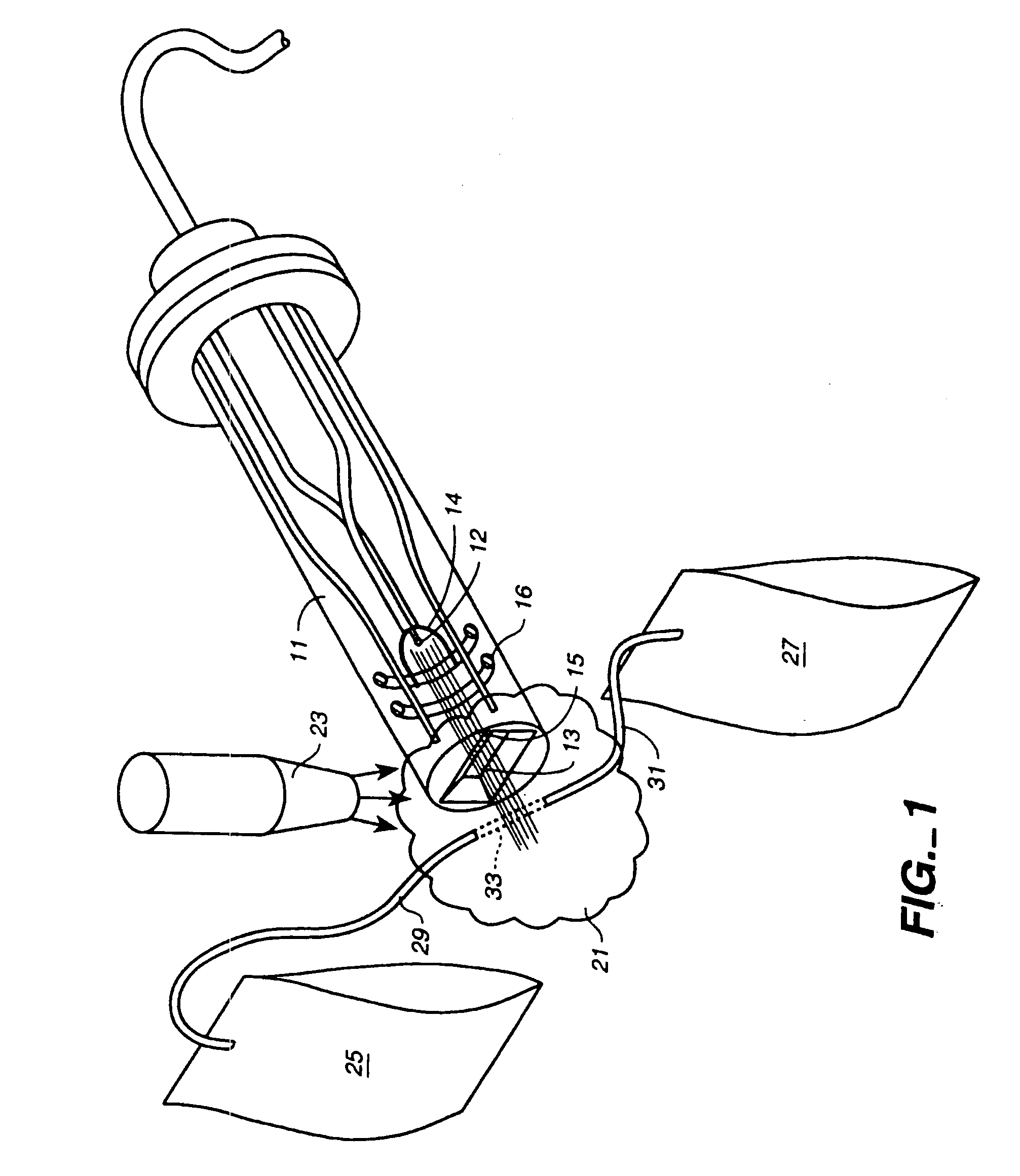

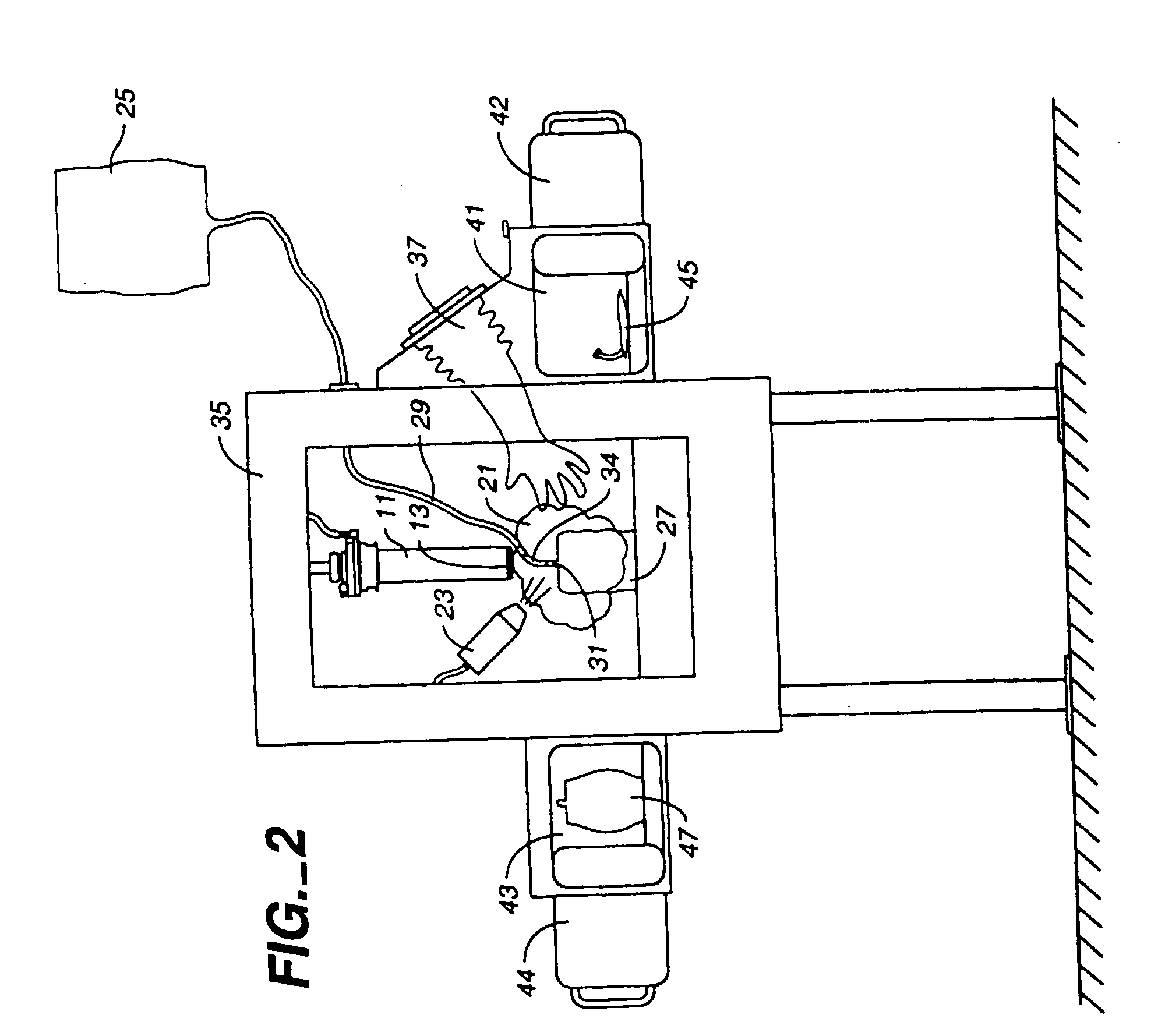

[0021]With reference to FIG. 1, an electron beam tube 11 is shown to have a window 13 through which a beam 15 emerges. Beam 15 is generated from a cathode 12 in front of an electrostatic focusing structure 14 and is further focused by a magnetic field generated by the helical coil 16. The detailed structure of beam tube 11 may be found in U.S. Pat. No. 5,612,588 to G. Wakalopulos, assigned to the assignee of the present invention. The thin window is only a few micrometers in thickness, or less, so that there is very little beam energy loss in penetrating the window. The window is preferably made of a material having a low atomic number so that electrons can readily penetrate the material, but gas molecules can not. This allows the interior of the tube to be at vacuum pressure while the outside of the tube is at ambient pressure, usually atmospheric pressure. The window is maintained at ground potential for safety reasons, while the cathode is maintained at a negative potential, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com