Patents

Literature

9results about How to "Simple clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining method of porous thin-wall fan cases and work-piece locating tool

InactiveCN105252051ASimple clampingImprove processing efficiencyMilling equipment detailsPositioning apparatusGypsumThin walled

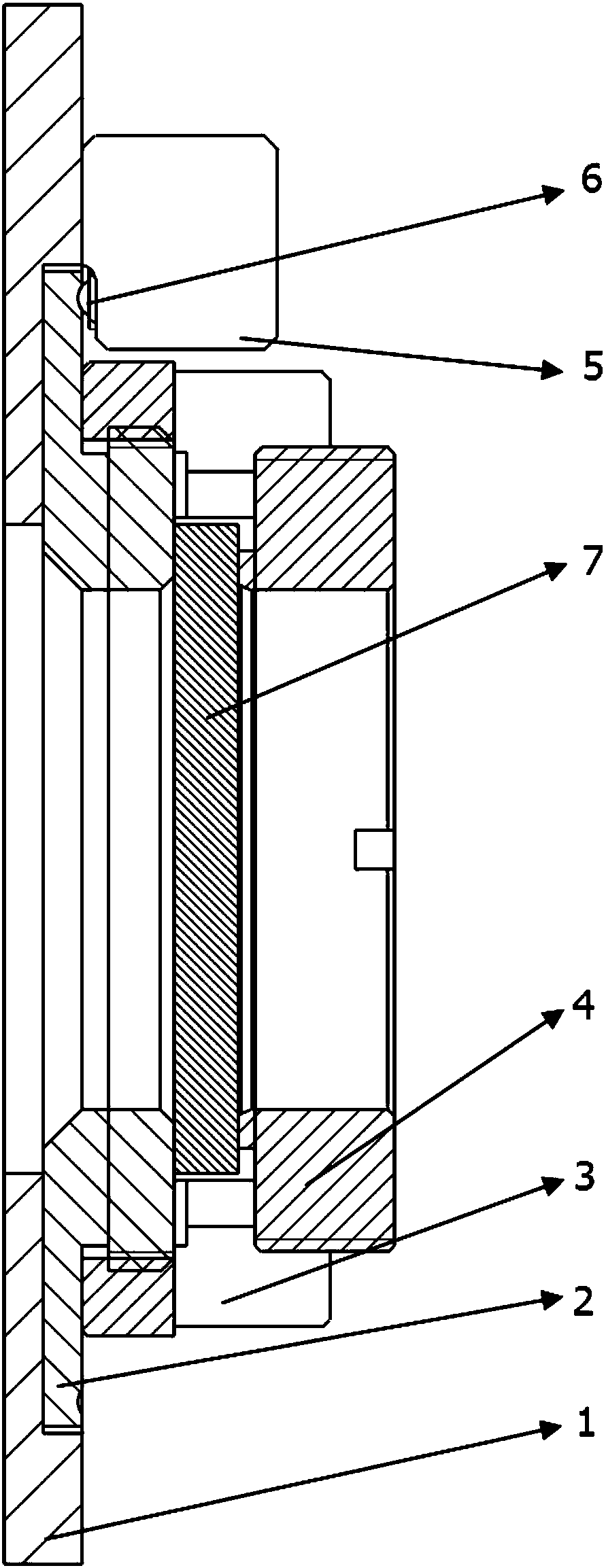

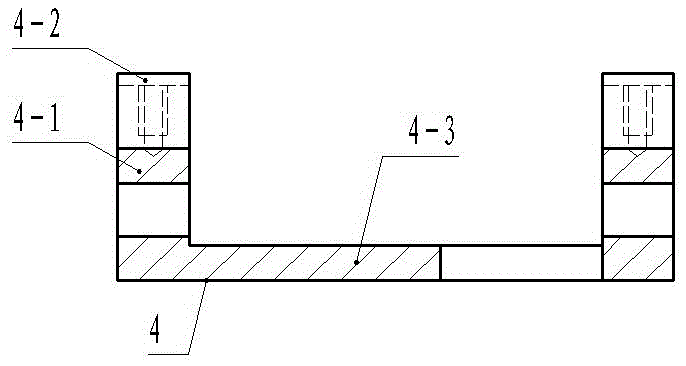

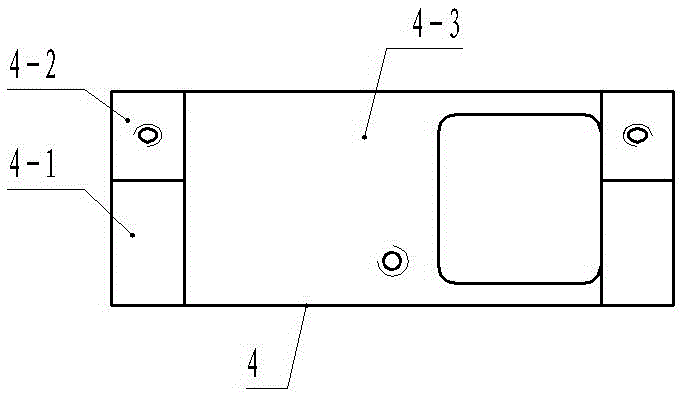

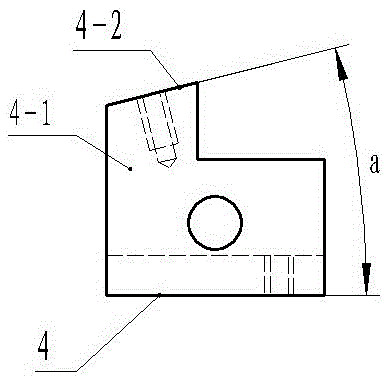

The invention discloses a machining method of porous thin-wall fan cases and a work-piece locating tool. The machining method of the porous thin-wall fan cases is high in machining efficiency and machining stability, and the tool is convenient to use. The machining method comprises the steps of roughly machining cavities of work-pieces; precisely machining the cavities of the work-pieces; machining threaded holes; roughly machining the peripheral contours of the work-pieces; uniformly coating the surface, making contact with the work-pieces, of the tool with fine gypsum powder with the thickness being 0.15 mm, slowly sleeving the tool with the cavities of the work-pieces and discharging the redundant gypsum powder between the tool and the work-pieces through the gap between the tool and the work-pieces; tensioning the work-pieces from the bottom surface of the tool through screws, and fixing the work-pieces through the friction force between the bottom surfaces of the work-pieces and the top surface of the tool; precisely machining the peripheral contours of the work-pieces; precisely machining the peripheral contours of the work-pieces again. By adopting the machining method, the clamping time of the work-pieces is shortened, machining deformation of thin-wall parts is controllable, the machining efficiency is high, and the machining stability of the thin-wall parts is improved.

Owner:TIANJIN UNIV OF COMMERCE

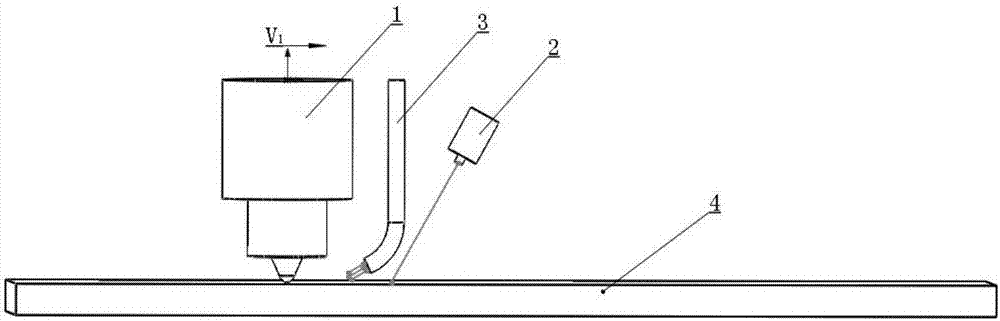

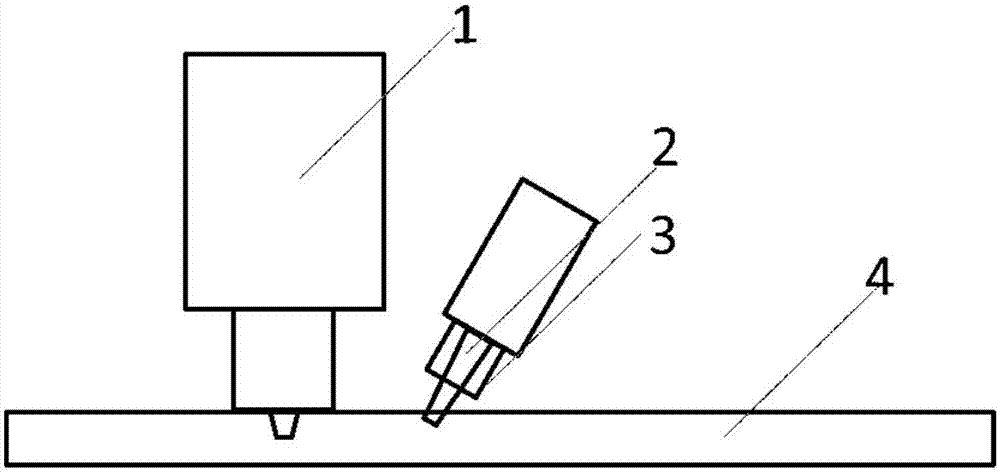

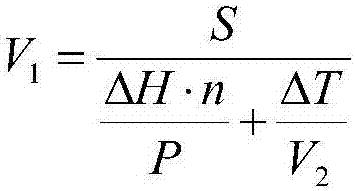

Method and device for friction stir welding (FSW) assisted by additional heat source

The invention discloses a method and a device for friction stir welding (FSW) assisted by an additional heat source and solves the problems of high FSW cost for high-melting-point materials such as steel, nickel-based alloys, titanium alloys and the like and short life of stir heads in the prior art. With the method and the device, a to-be-welded area reaches the semi-solid or superplastic state, so that rheology resistance of the high-melting-point materials can be substantially reduced, the welding moment can be reduced, the requirements for the performance of a stir head can be reduced, then abrasions of the stir head can be reduced, and the service life of a stir needle can be prolonged. According to the technical scheme, the device comprises the stir head for welding, an additional heat source component and a gas shielding device; the stir head is rotationally inserted into a butt weld or an overlapping weld of a workpiece and can move; the additional heat source component is used for providing heat for the workpiece to form an additional heat source heating area on the surface of the workpiece, is arranged in front of the stir head and is spaced from the stir head by the set distance; and the gas shielding device is located above the additional heat source heating area and / or in front of the stir head.

Owner:SHANDONG UNIV

Multi-station milling clamp for casing flanges

InactiveCN103707096AProcess accuracy is easy to guaranteeSimple clampingPositioning apparatusMetal-working holdersEngineeringWorkbench

The invention relates to a multi-station milling clamp for casing flanges, wherein the multi-station milling clamp is used for machining the planes of bosses of CN100 and CN100B15 casing flanges. The multi-station milling clamp for the casing flanges is provided with a base plate connected with a milling machine workbench, a plurality of casing flange stations are arranged on the base plate in the vertical direction and the left and right direction at intervals, each casing flange station is provided with at least two positioning pins used for positioning the casing flange located in the station, a through hole is formed between every two adjacent casing flange stations and used for a bolt to penetrate through, each bolt is connected with a pressing plate in a sleeved mode, and the pressing plates are used for fixing the casing flanges to the base plate when the bolts are screwed down. The multi-station milling clamp for the casing flanges has the advantages that the problem that the single-piece machining of a common milling machine in the prior art is far from meeting the requirement of a main machine plant order is solved, the milling clamp is changed and installed on a full-automatic numerical control milling machine, multiple pieces are machined in a combined mode, the technological precision is easy to guarantee, and the clamping is easy to perform; excess supply is guaranteed, the multiple pieces can be machined fully automatically, and the working efficiency is improved.

Owner:LIUZHOU KEERTE FORGING MACHINERY

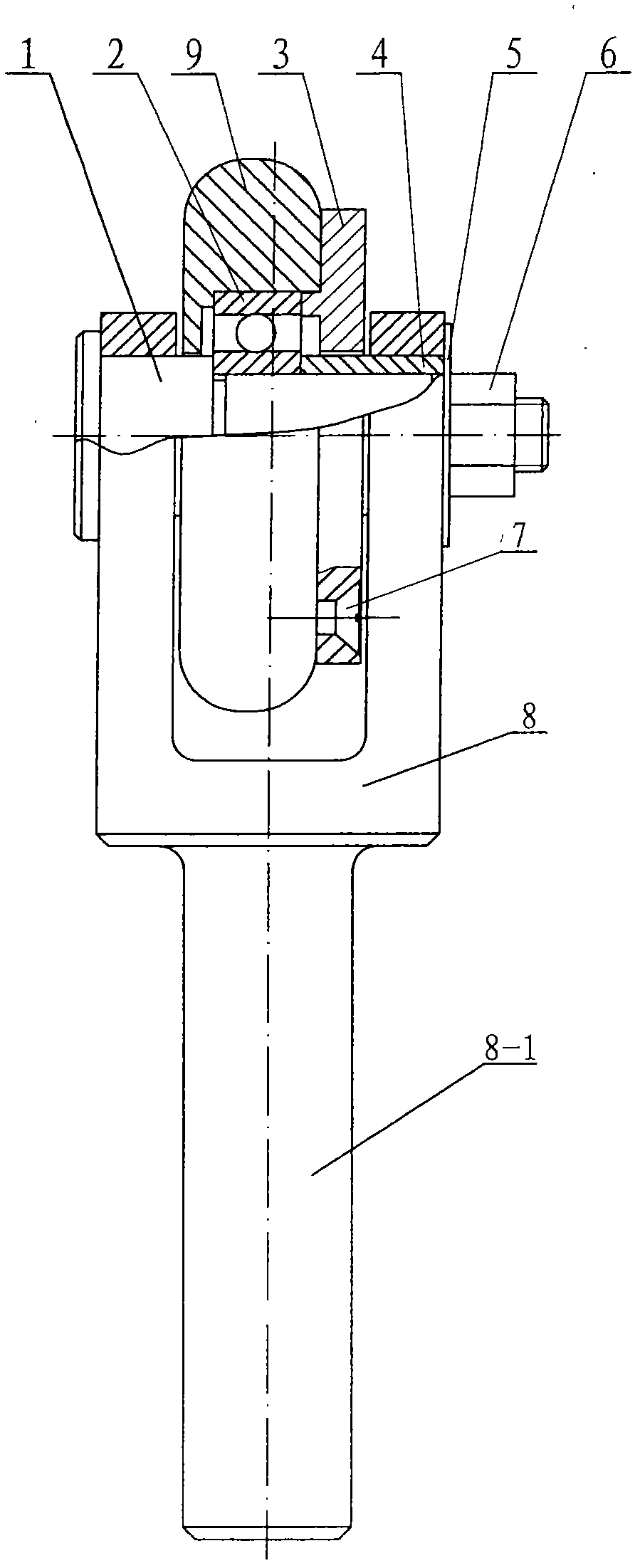

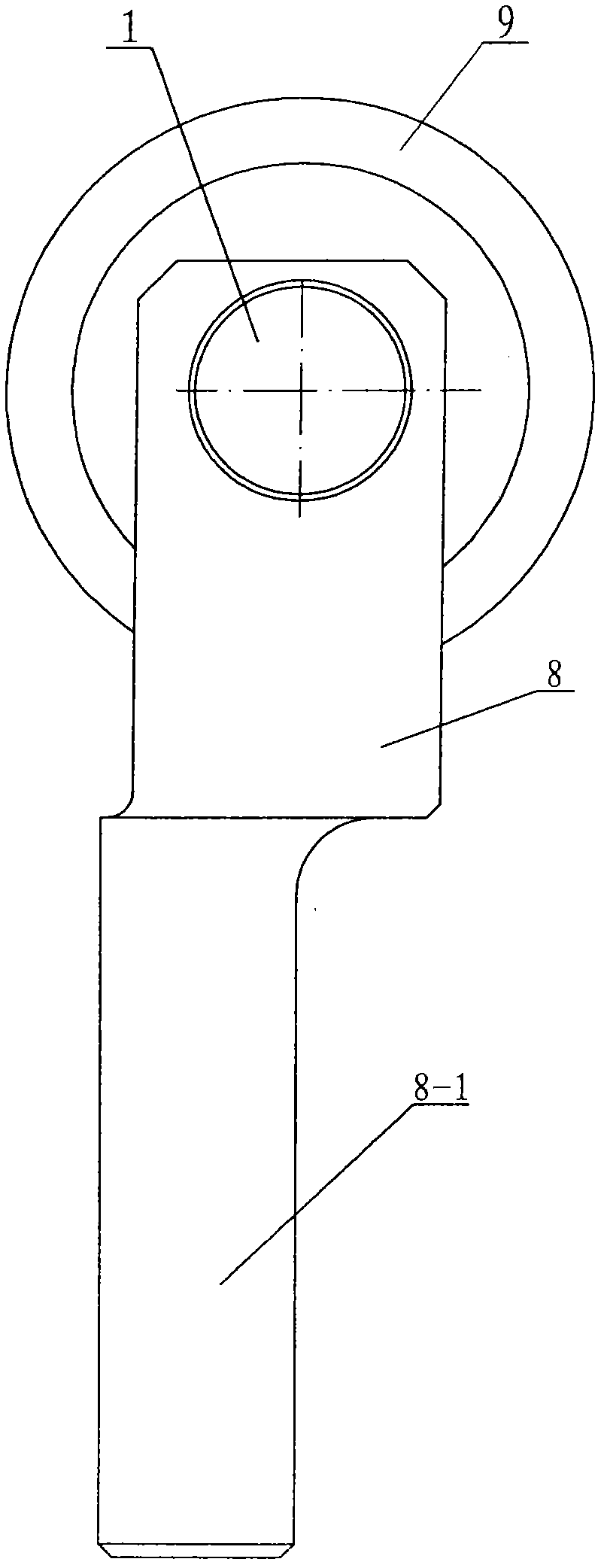

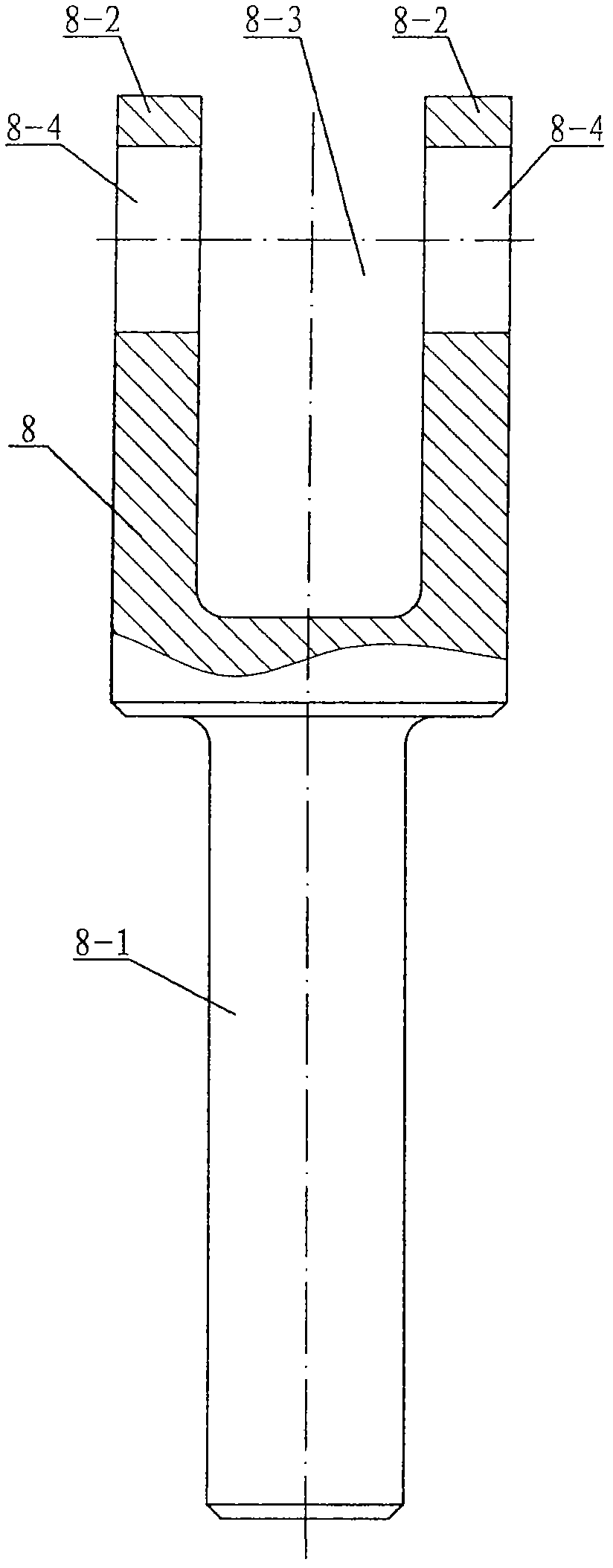

Turning, closing-up and rib rolling device for tube parts

A turning, closing-up and rib rolling device for tube parts relates to closing-up and rib rolling devices for tube parts and solves the problem that a die used for closing up tube parts is complicated in structure, long in processing cycle, high in cost and poor in universality. Stepped holes are arranged at an axial center of a roller, the outer surface of the roller is an outwardly protruded arc surface, a bearing is arranged in a bearing mounting hole, a pressing section on a press ring is disposed in the bearing mounting hole, the end surface of the pressing section presses an outer ring of the bearing tightly, the press ring is connected with the roller through screws, a roller rack is of a shifting fork structure, an assembly consisting of the roller, the bearing and the press ring is disposed in a groove, a threaded end of a shaft sequentially penetrates through a lateral shaft mounting hole, a roller inner hole, an inner hole of the bearing, a through hole and another lateral shaft mounting hole, a limiting sleeve is sleeved on the shaft and presses an inner ring of the bearing tightly, a gasket is sleeved at the threaded end of the shaft, and a nut is connected with the threaded end of the shaft in a threaded manner. The turning, closing-up and rib rolling device of the invention is used for realizing turning, closing-up and rib rolling on serial tube parts with identical shapes and different outer diameters.

Owner:HARBIN JIANCHENG GRP

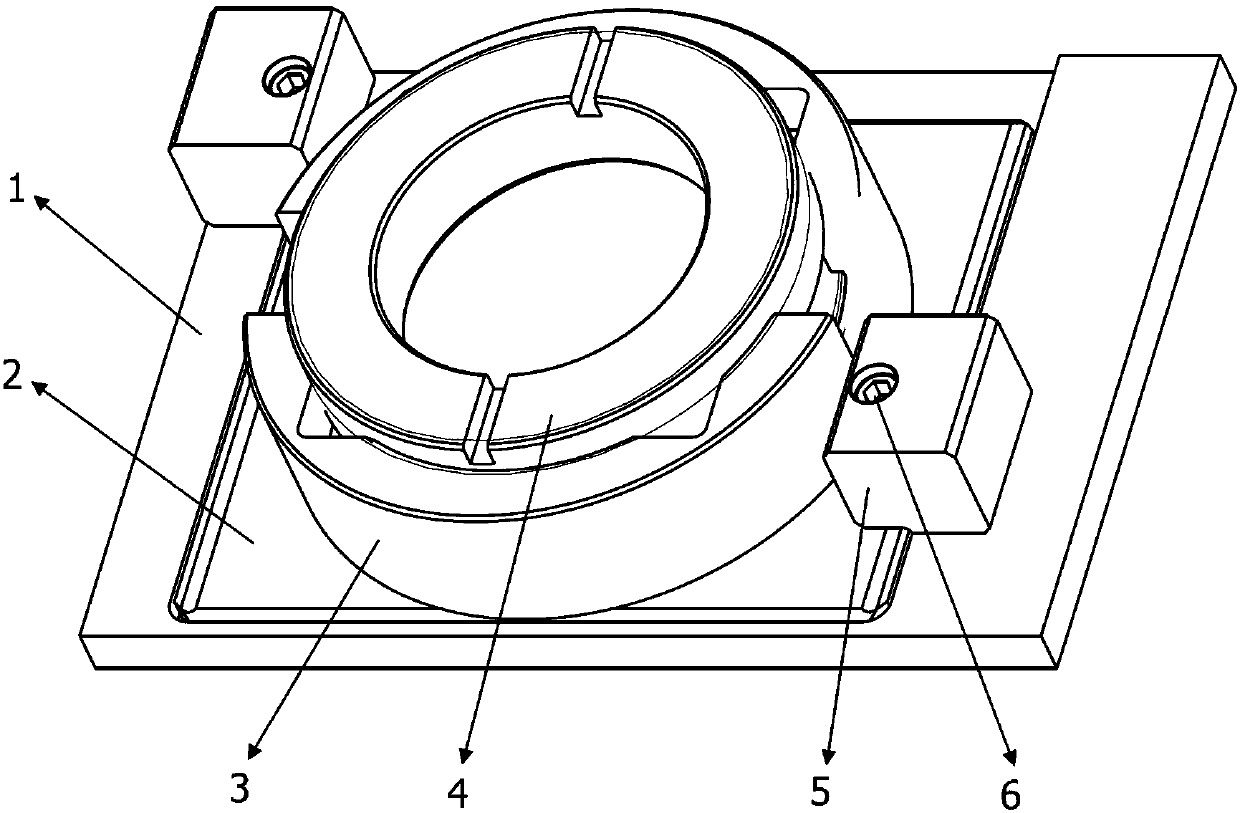

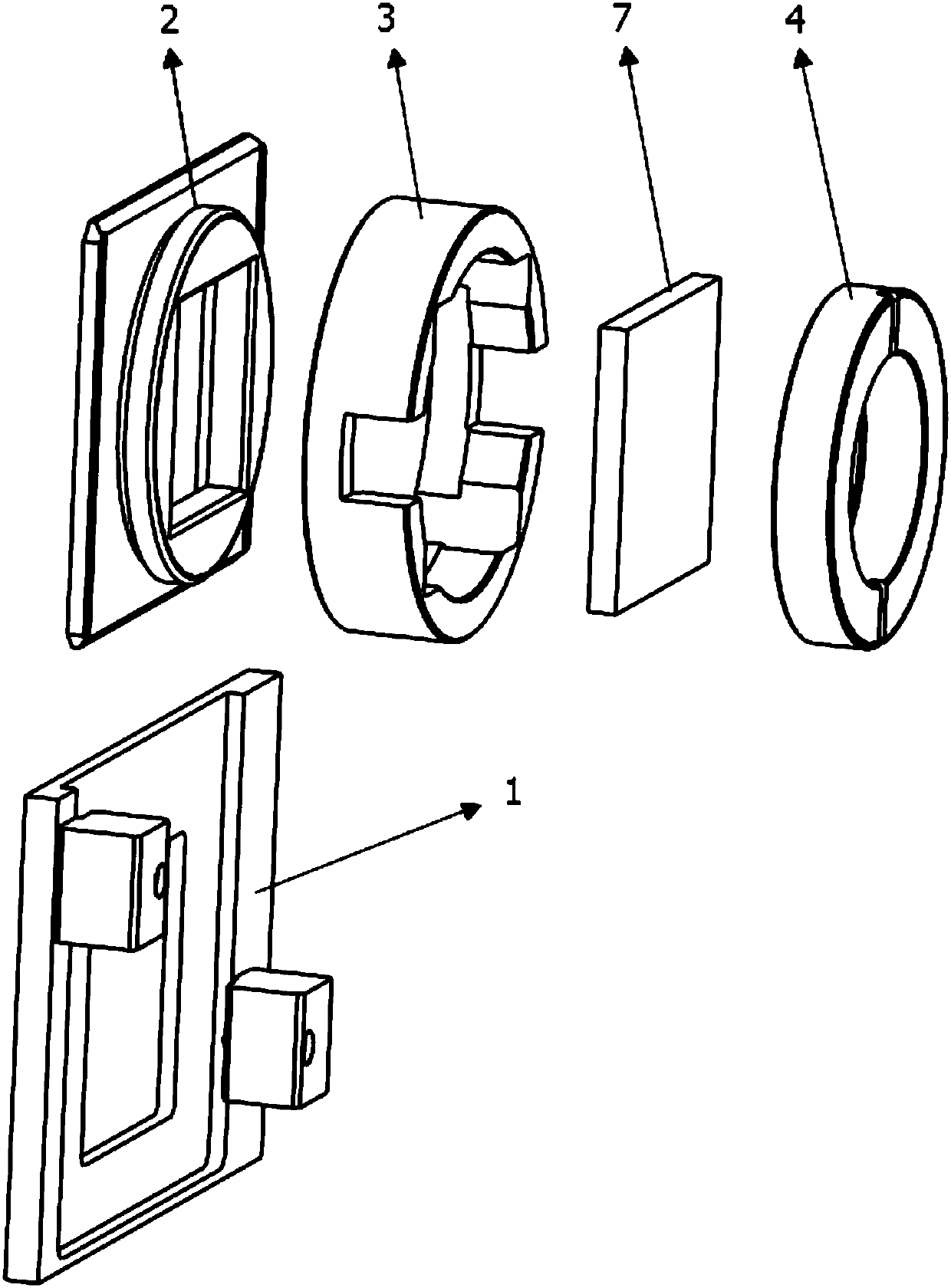

Optical element quick replacing and positioning device

PendingCN108044542ASimple clampingImprove detection efficiencyMaterial analysis by optical meansWork holdersCamera lensEngineering

The invention discloses an optical element quick replacing and positioning device. The optical element quick replacing and positioning device comprises a mother fixture base, and a son fixture base detachably connected with the mother fixture base; a boss is arranged on one side of the son fixture base, and is detachably connected with a son fixture outer ring; and a pressing plate is detachably connected into the son fixture outer ring. The optical element quick replacing and positioning device has the following beneficial effects that mother and son fixtures are used for clamping and positioning; and the son fixture is simple in clamping, so that quick replacement and clamping during film detection of optical glass can be realized, and the detecting efficiency is improved; meanwhile, thefixtures can adapt to the optical glass in such different shapes as rectangles and circles, and can adapt to changes of section sizes and thickness sizes within a certain range; and in addition, thefixtures can simply realize accurate positioning of the surfaces, plated with optical films, of the optical glass to guarantee stable and invariable distances from the surfaces of the films to lenseseach time during replacement of the optical glass.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

Machining method for rotating shaft bearing bases

InactiveCN106001717AIncrease productivitySimple clampingMilling equipment detailsPositioning apparatusMachiningBolt connection

The invention discloses a machining method for rotating shaft bearing bases, and relates to the technical field of machining. A rotating shaft bearing base milling clamp is used for conducting machining and comprises a base. The base is provided with two positioning inclined blocks which are oppositely arranged. The high portions of the two positioning inclined blocks are connected. Each positioning inclined block has a positioning face. The included angles between the positioning faces and the bottom faces of the positioning inclined blocks are alpha. Pressing plates are connected to the positioning faces through bolts. The two ends of each positioning inclined block are each provided with a limiting boss. The low portions of the positioning inclined blocks are connected with limiting blocks. The machining steps of the machining method include the first step of clamp installation, the second step of workpiece installation, the third step of face milling and the fourth step of rotating shaft bearing base detachment. Compared with the prior art, the two rotating shaft bearing bases can be clamped at a time for inclined face machining, the production efficiency is high, the rotating shaft bearing base clamping is easy, and operation is convenient.

Owner:WUZHOU OKA OPTICAL INSTR

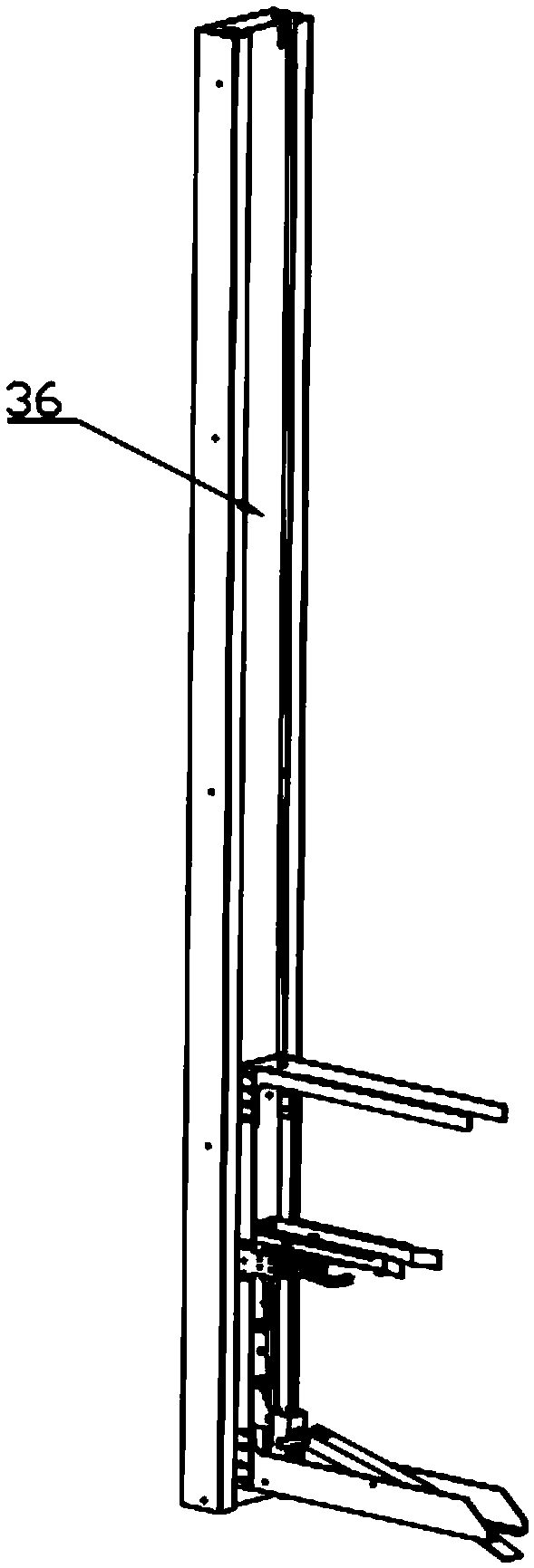

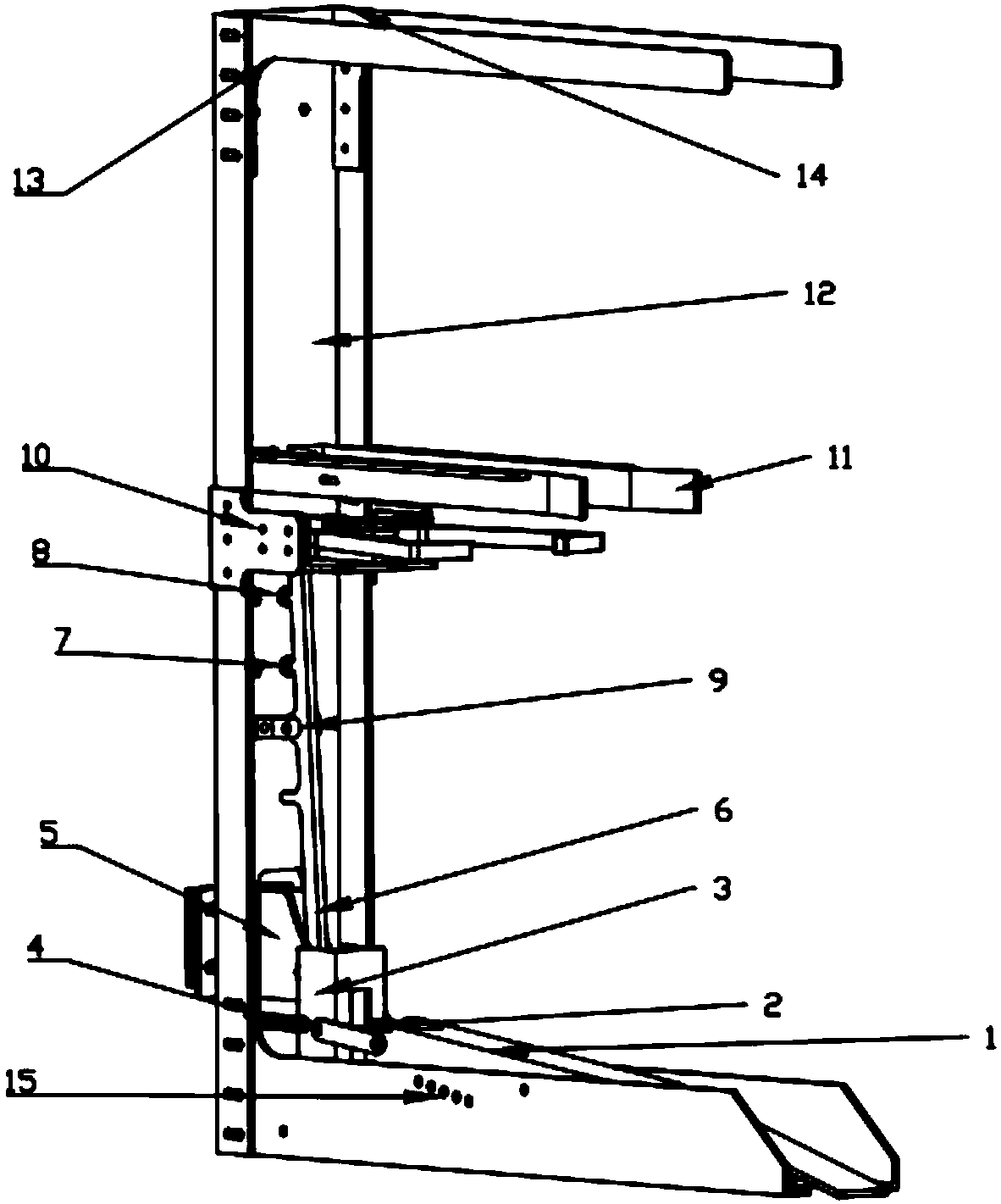

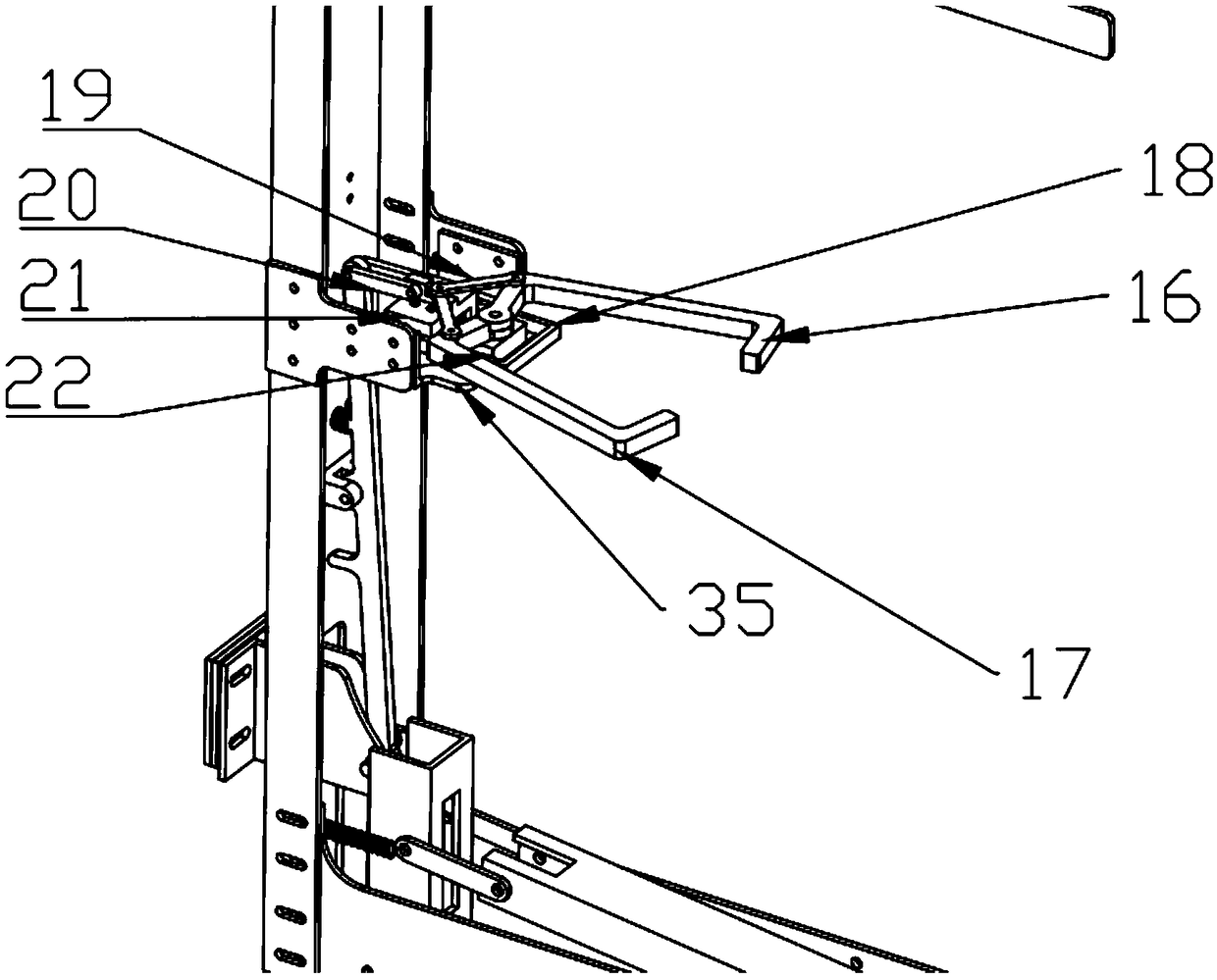

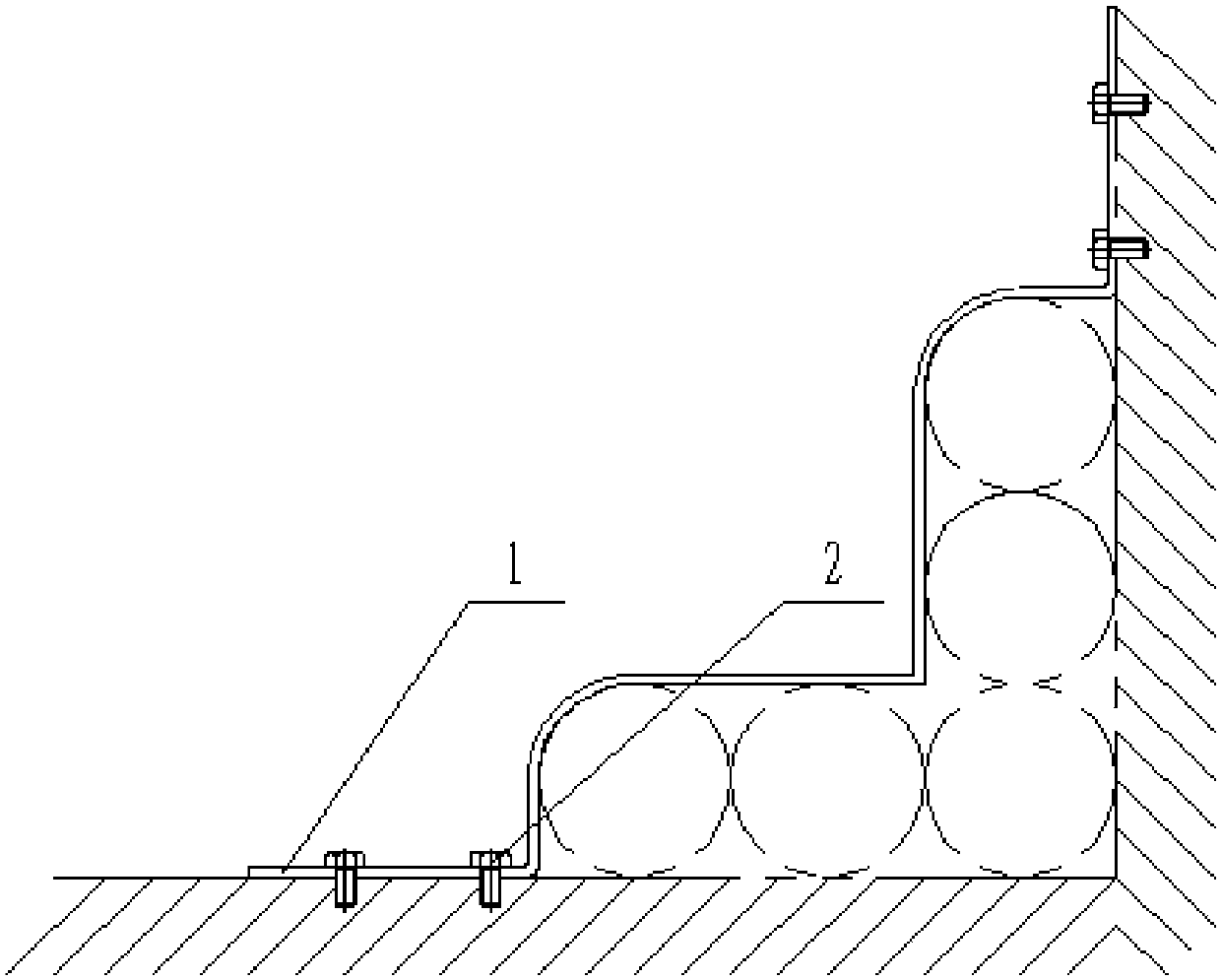

Vertical bicycle auxiliary parking device

The invention discloses a vertical bicycle auxiliary parking device, comprising a clamping device for fixing a bicycle front wheel, a lifting device for lifting the front wheel, a slide rail for guiding the lifting and lowering of the front wheel, and a bracket for supporting the integral device. The device lifts the entire clamping device and the front wheels by the spring force of the compression spring, pushes the bicycle for the first time so that the clamping device clamps the front wheels, and then gives a slight vertical upward force to the bicycle to stand upright under the action of the spring, and lowers the clamping device and the front wheels by giving a slight downward pulling force. The vertical bicycle parking assistant device not only can greatly reduce parking space, but also has the advantages of simple structure, low manufacturing cost, convenient use, no power supply, and is suitable for all types of bicycles.

Owner:JILIN UNIV

Right-angled wire clamping clip

InactiveCN109936077AFixture structure is stableSimple clampingApparatus for overhead lines/cablesEngineeringMechanical engineering

Owner:绍兴中普防雷科技有限公司

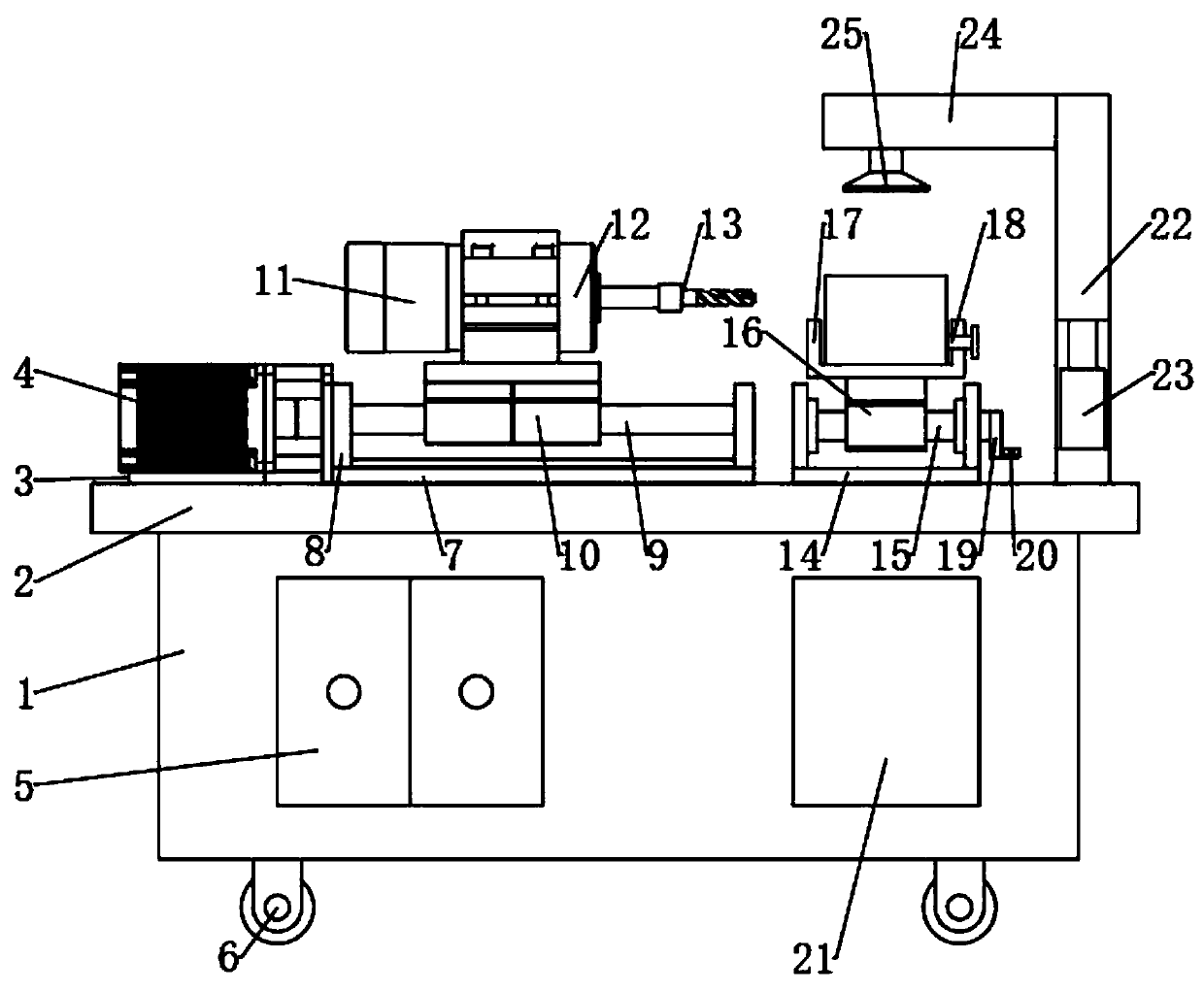

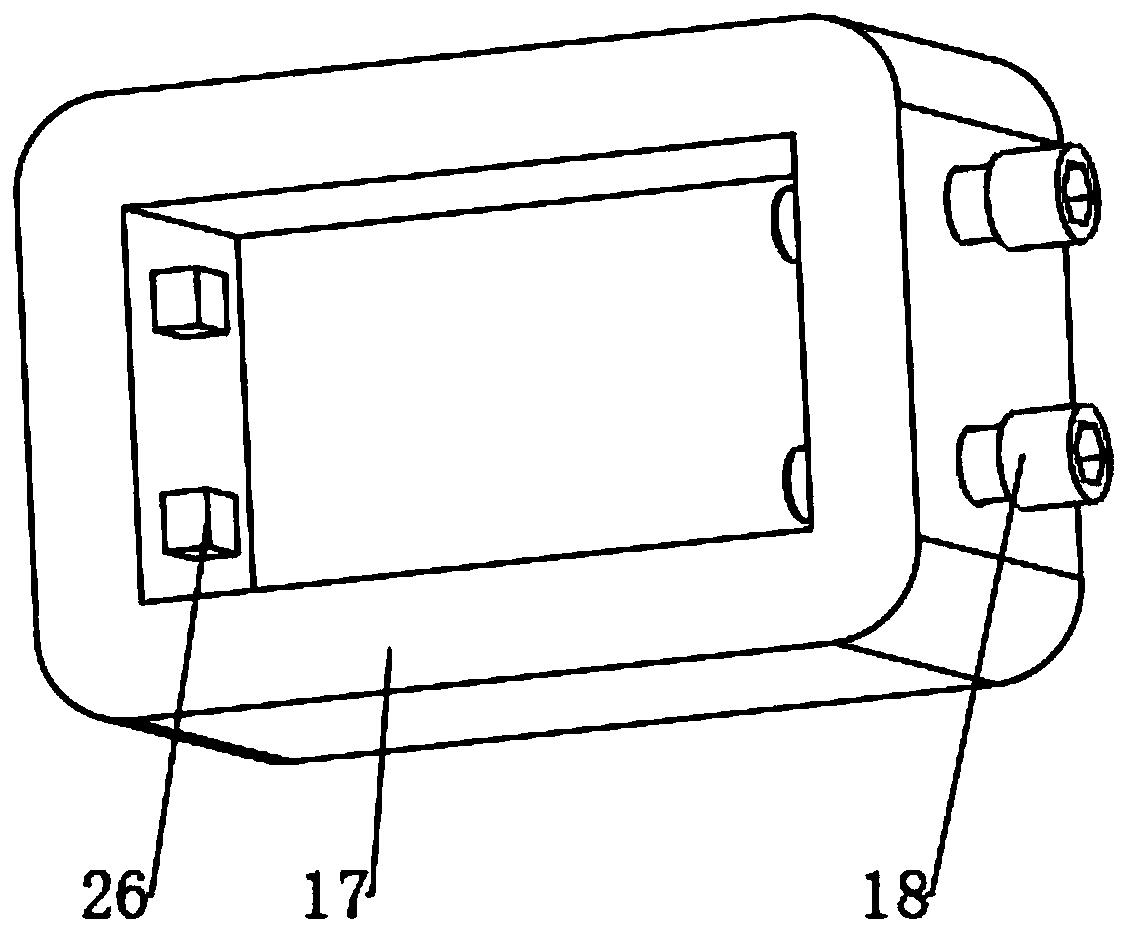

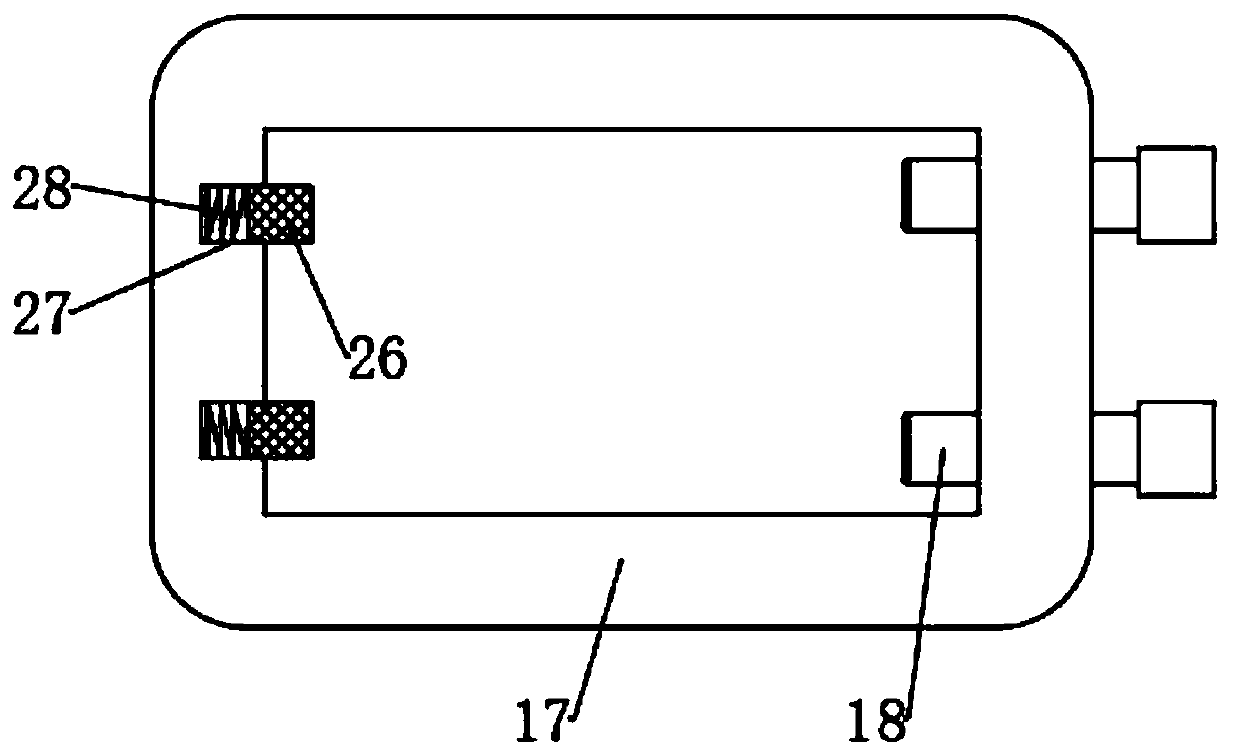

Small drilling machine

InactiveCN111037334AEasy to operateSimple clampingFeeding apparatusPositioning apparatusPhysicsElectric machinery

The invention discloses a small drilling machine. The small drilling machine comprises a machine body; a workbench is arranged on the upper end face of the machine body; a feeding mechanism and a clamp are arranged on the workbench at intervals; and a workpiece is installed in the clamp. The small drilling machine is simple in operation, is easy to clamp the workpiece and is suitable for being popularized in college engineering training centers. The punching rate of a cutter is controlled through a feeding motor, so that drilling is smoother and more uniform; a sliding mechanism is connected at the lower part of a mounting seat, so that a distance between the workpiece and the cutter can be changed by shaking a handle, and therefore, operation is convenient; a cooling mechanism is arrangedabove the workpiece, so that water can be sprayed out of a spray head to cool the cutter during punching, and therefore, the service life of the cutter can be prolonged; a storage cabinet is arrangedin the machine body, so that operation tools can be stored and are convenient to take; and universal wheels are arranged at the lower part of the machine body, so that an operator can move the machine just by pushing the machine body, and therefore, the labor intensity of the operator is reduced.

Owner:朱骏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com