Paint for forming transparent conductive layer

A transparent conductive layer and display device technology, applied in conductive coatings, conductive materials dispersed in non-conductive inorganic materials, static electricity, etc., can solve problems such as unnatural color of conductive film transmission images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0102] - Preparation of coating material for forming transparent conductive layer:

[0103] Aqueous palladium sol 15g

[0104] Mercury sol 35g

[0105] Isopropanol 10g

[0106] Ethanol 40g

[0107] The above-listed components were mixed together, and then the resultant fluid mixture was made into a dispersion liquid through an ultrasonic diffusion machine ("Sonifer 450" of BRANSON Ultrasonic Instrument Manufacturing Co., Ltd.) to prepare the transparent conductive layer-forming coating material of Example 1. .

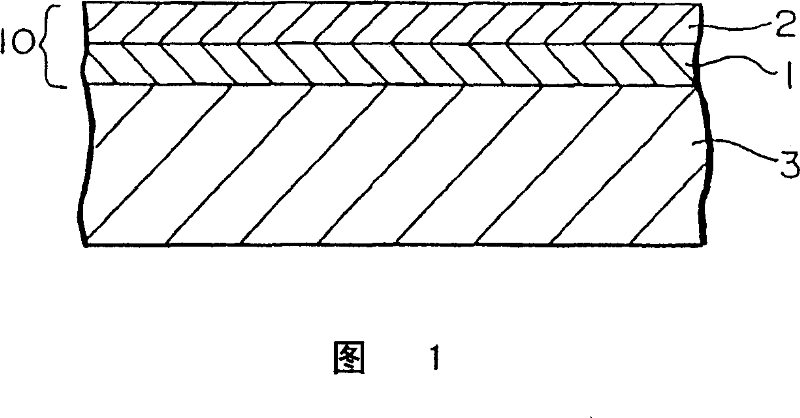

[0108] - Membrane formation:

[0109] The above-mentioned paint for forming a transparent conductive layer was coated on a display screen of a kinescope using a spin coater. After carrying out the drying treatment, utilize the above-mentioned transparent conductive layer forming coating to be coated on the surface of the above-mentioned coating in the same way again by using a spin coater, then this picture tube is put into a drying box, and at 150 ℃ Bake for 1 h...

example 2

[0111] - Preparation of coating material for forming transparent conductive layer:

[0112] Aqueous palladium sol 35g

[0113] Mercury sol 15g

[0114] Isopropanol 10g

[0115] Ethanol 40g

[0116] The above-listed components were mixed together, and then the transparent conductive layer-forming paint of Example 2 was prepared in the same manner as in Example 1.

[0117] - Membrane formation:

[0118] The above-mentioned paint for forming a transparent conductive layer was used and processed in the same manner as in Example 1 to produce an anti-reflection, high-conductivity coating film cathode ray tube.

example 3

[0120] - Preparation of coating material for forming transparent conductive layer:

[0121] Aqueous palladium sol 45g

[0122] Mercury sol 5g

[0123] Isopropanol 10g

[0124] Ethanol 40g

[0125] The above-listed components were mixed together, and then the transparent conductive layer-forming paint of Example 3 was prepared in the same manner as in Example 1.

[0126] - Membrane formation:

[0127] The above-mentioned paint for forming a transparent conductive layer was used and treated in the same manner as in Example 1 to produce an antireflection, high-conductivity coating film cathode ray tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com