Method of preventing solid adhesion

A solid material and material technology, applied in the direction of pipeline heating/cooling, mechanical equipment, pipes/pipe joints/fittings, etc., to achieve the effect of suppressing the rise of supersaturation, preventing the precipitation of impurities, and preventing the reduction of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

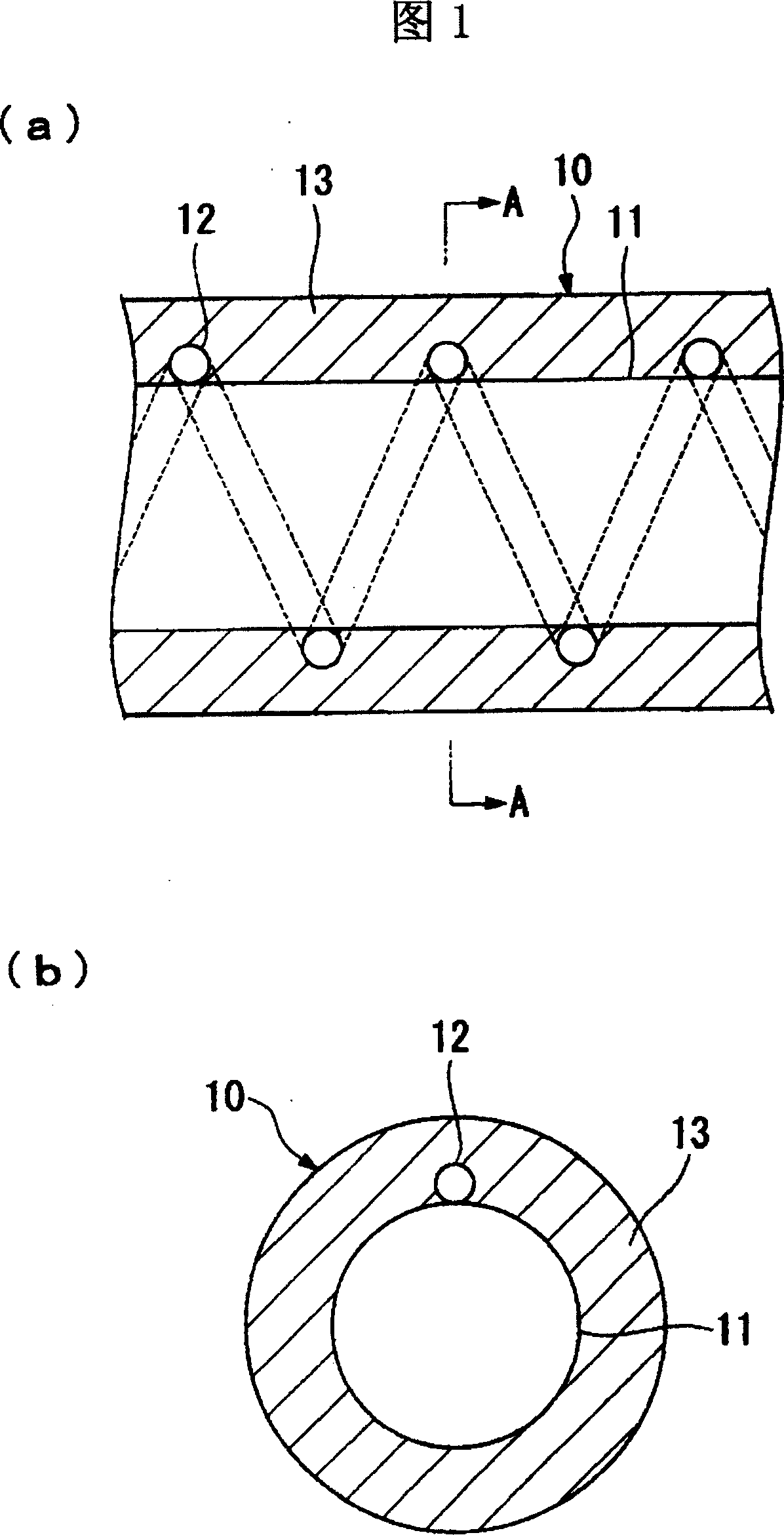

[0030] In a stainless steel pipe with an outer diameter of 114.3mm, a thickness of 3.0mm, and a length of about 20m, at a temperature of 94°C and a flow rate of 34m 3 A methacrylic acid-containing solution containing methacrylic acid: 99% by mass and other impurities: 1% by mass (of which terephthalic acid: 800ppm) was circulated under the condition of / h (flow rate was adjusted by a control valve). A copper tube with an outer diameter of 8 mm and a thickness of 1 mm was wound as a heating device on the outside of the tube at a pitch of 50 mm, and steam at a temperature of 144° C. circulated inside the copper tube. In addition, the pipes and copper pipes through which the methacrylic acid-containing solution flows were covered with glass wool having a thickness of 50 mm to keep them warm.

[0031] After continuing to circulate in this state for 3 months, the solution containing methacrylic acid was drained, and the inside of the pipe was judged by visual observation. As a res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com