Non-volatile memory with improved coupling rate and its making method

A non-volatile storage and conductive layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of reducing the dielectric layer, difficult charge pump design, increasing internal polysilicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below with an example of a non-volatile semiconductor memory device. It should be understood, however, that the present invention is not limited to the use of a particular type of device or memory cell, and that the present invention is more broadly applicable to any semiconductor device in which internal impedance is a concern. Furthermore, while the present invention is well suited for use in non-volatile semiconductor memory devices, it also provides significant advantages in numerous other applications.

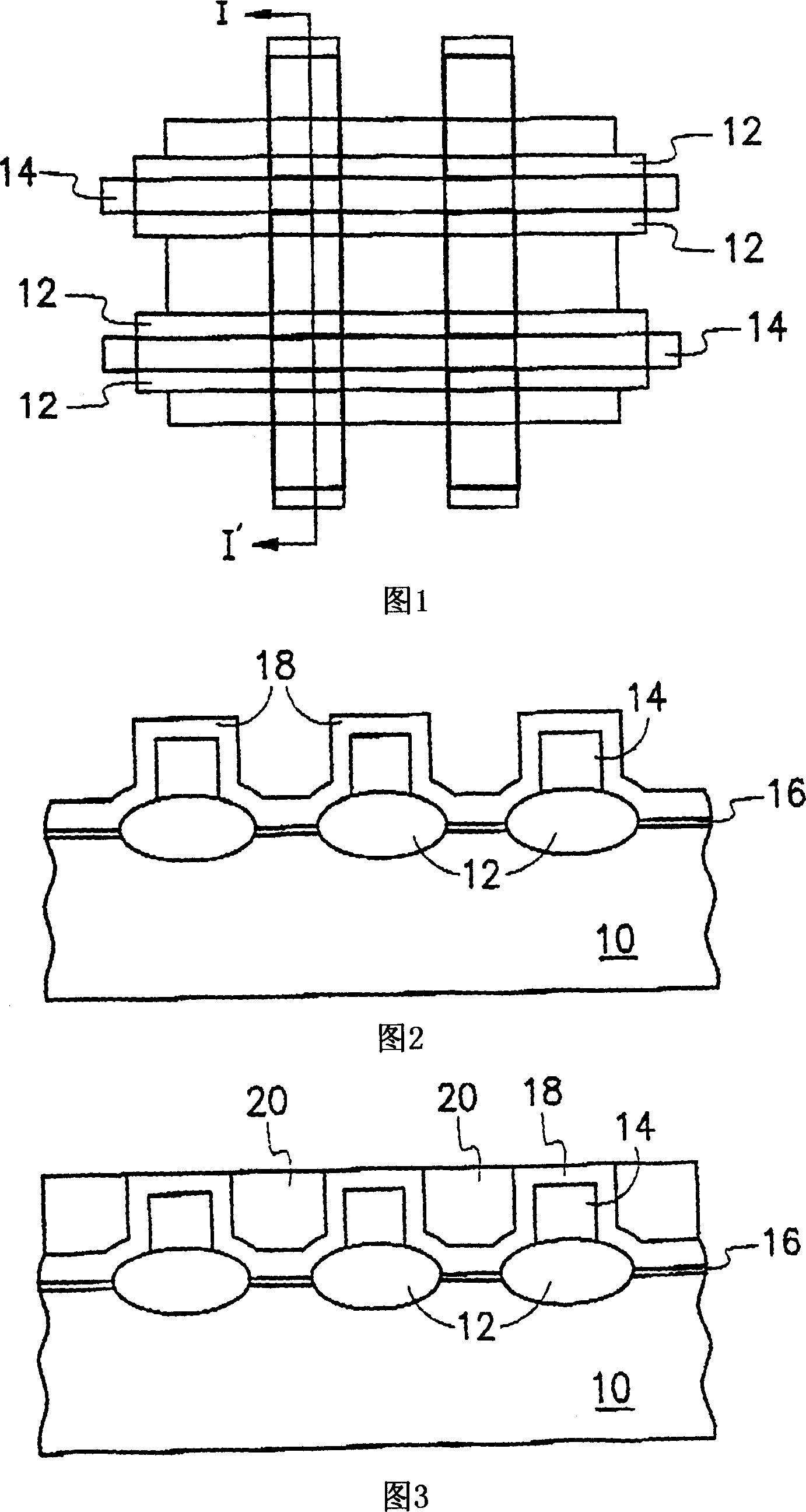

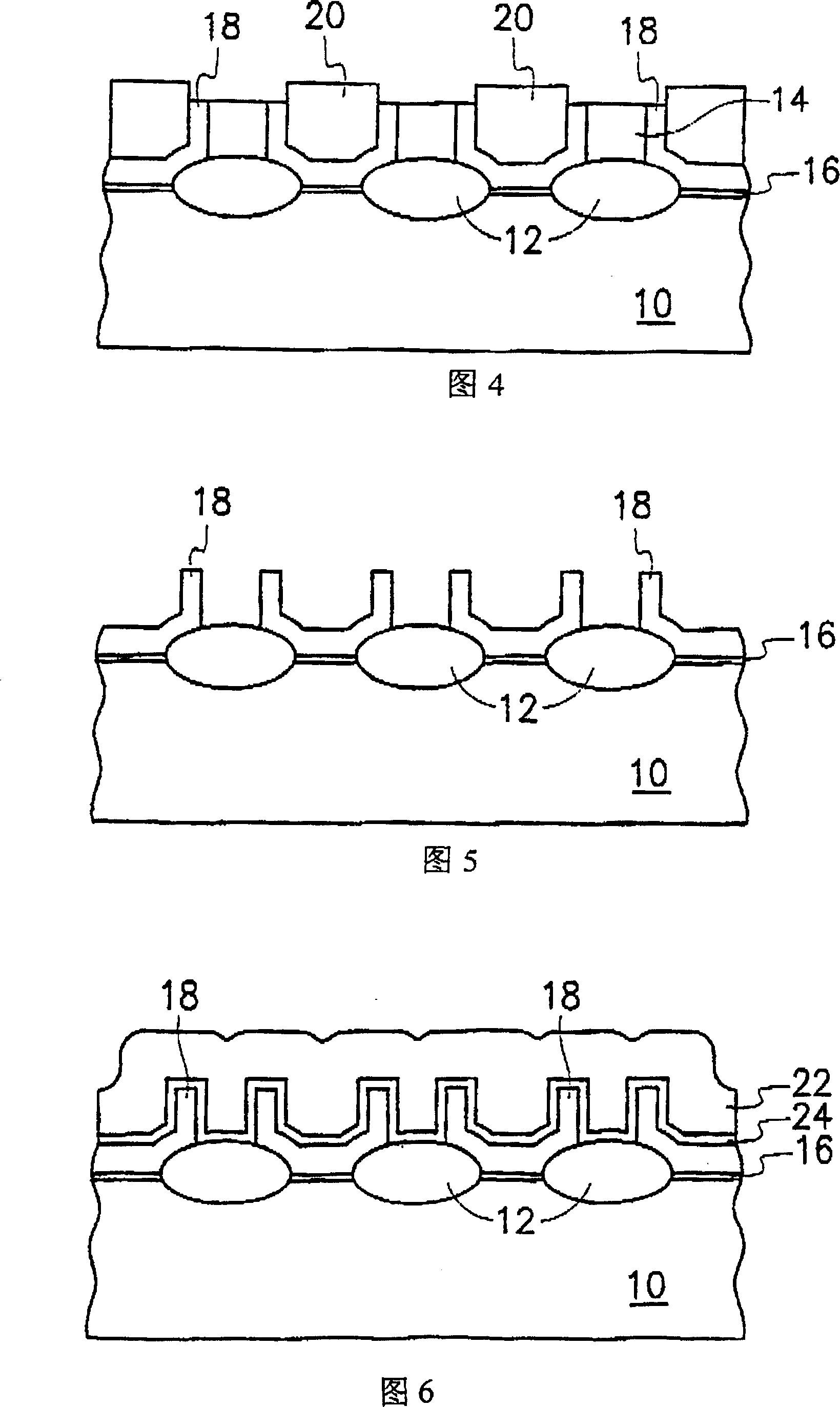

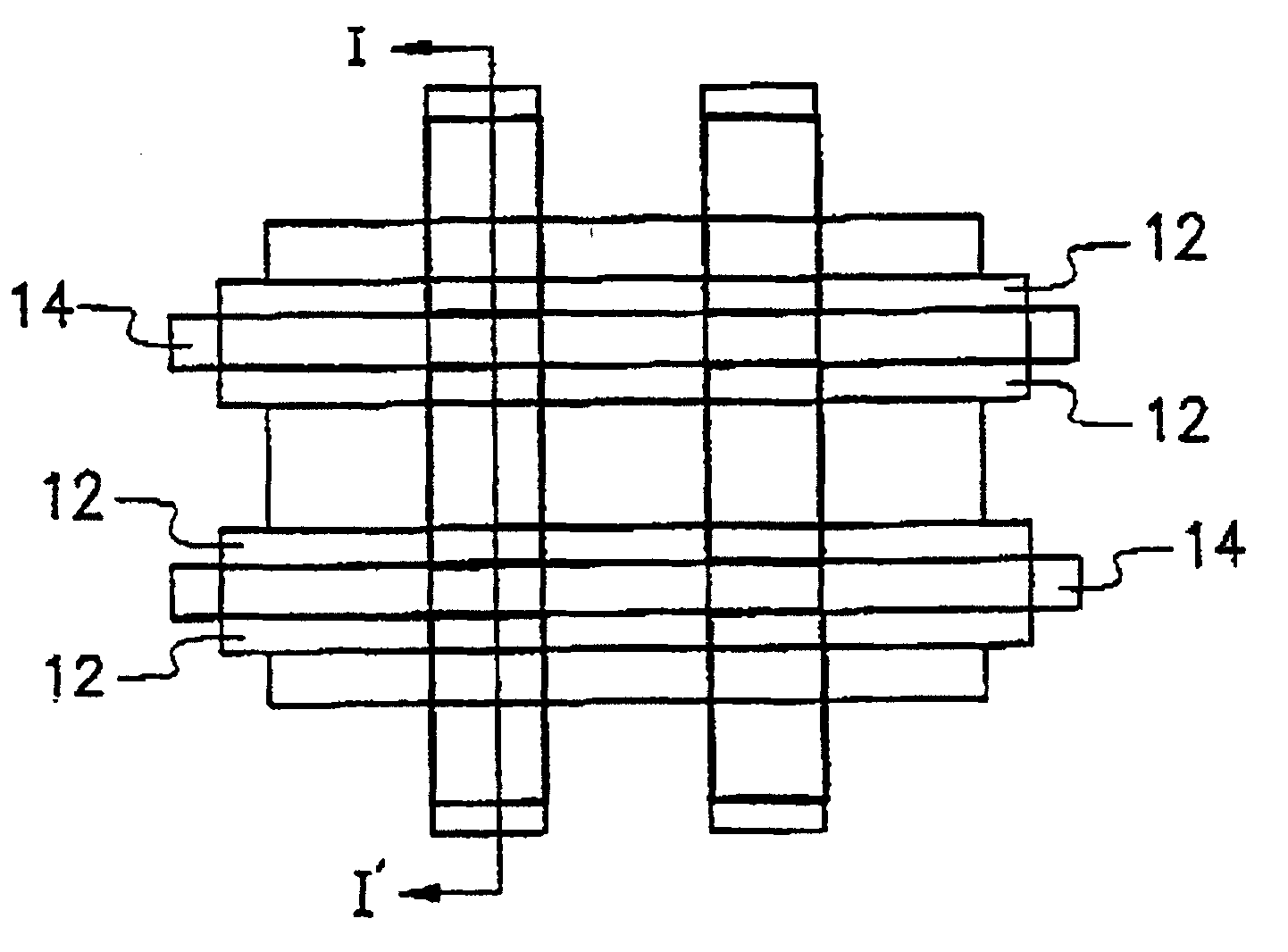

[0028] 1 to 6 show the process of forming an embodiment of the present invention, please refer to FIG. 1 and FIG. 2 (FIG. 2 is a cross-sectional view along the I'-I plane of FIG. As a starting point, a long line of an isolation region 12 is formed in the silicon substrate 10 by, for example, an area oxidation method, a first dielectric layer (for example, silicon nitride) 14 is formed on the isolation region 12 and the silicon sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com