Gadolinium-doped nanometer composite material, and its prepn. method

A nano-composite material and composite material technology, applied in the material field of MRI molecular imaging and molecular therapy research, can solve the problems of difficult differential diagnosis, lack of characteristic imaging performance, etc., and achieve enhanced relaxation rate and enhanced paramagnetism. , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

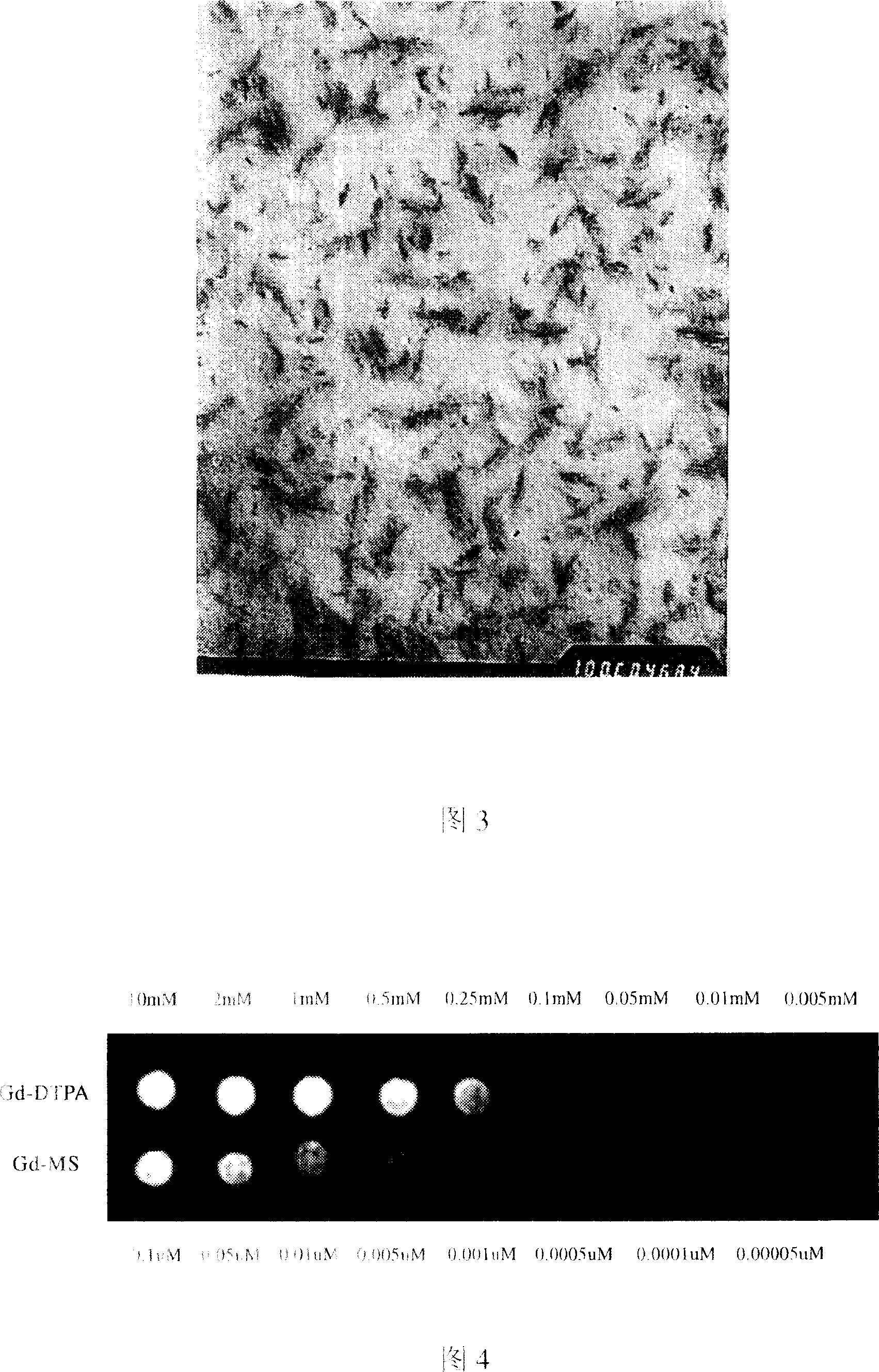

[0046] Example 1 Using the nonionic surfactant Pluronic P123 as a template and tetramethoxysilane as a silicon source to synthesize gadolinium-doped nanocomposites:

[0047] 2.3 millimoles of nonionic surfactant Pluronic P123 were dissolved in 30 milliliters of distilled water at 37 ° C, under ultrasonic vibration, Pluronic P123 was completely dissolved; then add 4 milliliters of concentrated hydrochloric acid (37%); continue to add 7 milliliters of mol tetramethoxysilane and 0.40 mmol GdCl 3 ·6H 2 O, the reaction was carried out for 7 minutes. Then, under ultrasonic vibration, the reaction solution was poured into 400 ml of 0.5 mol / L ammonia solution. The reaction was carried out for 20 minutes. The nanomaterials were collected by centrifugation (12000 rpm), dried at room temperature, and calcined at 300° C. for 4 hours to obtain the gadolinium-doped nanocomposite material. The obtained gadolinium-doped nanocomposite material has an average particle diameter of 34 nm, and...

Embodiment 2

[0048] Example 2 Using the nonionic surfactant Pluronic P123 as a template and tetraethoxysilane as a silicon source to synthesize gadolinium-doped nanocomposites:

[0049] 2.8 millimoles of nonionic surfactant Pluronic P123 were dissolved in 30 milliliters of distilled water at 37°C, under ultrasonic vibration, Pluronic P123 was completely dissolved; then 4 milliliters of concentrated hydrochloric acid (37%) was added; mol tetraethoxysilane and 0.30 mmol GdCl 3 ·6H 2 O, the reaction was carried out for 7 minutes. Then, under ultrasonic vibration, the reaction solution was poured into 500 ml of 0.5 mol / L ammonia solution. The reaction was carried out for 30 minutes. The nanomaterials were collected by centrifugation (12000 rpm), dried at room temperature, and calcined at 400°C for 4 hours to obtain the gadolinium-doped nanocomposite material. The obtained gadolinium-doped nanocomposite material is composed of particles with an average particle diameter of 38 nm, and the av...

Embodiment 3

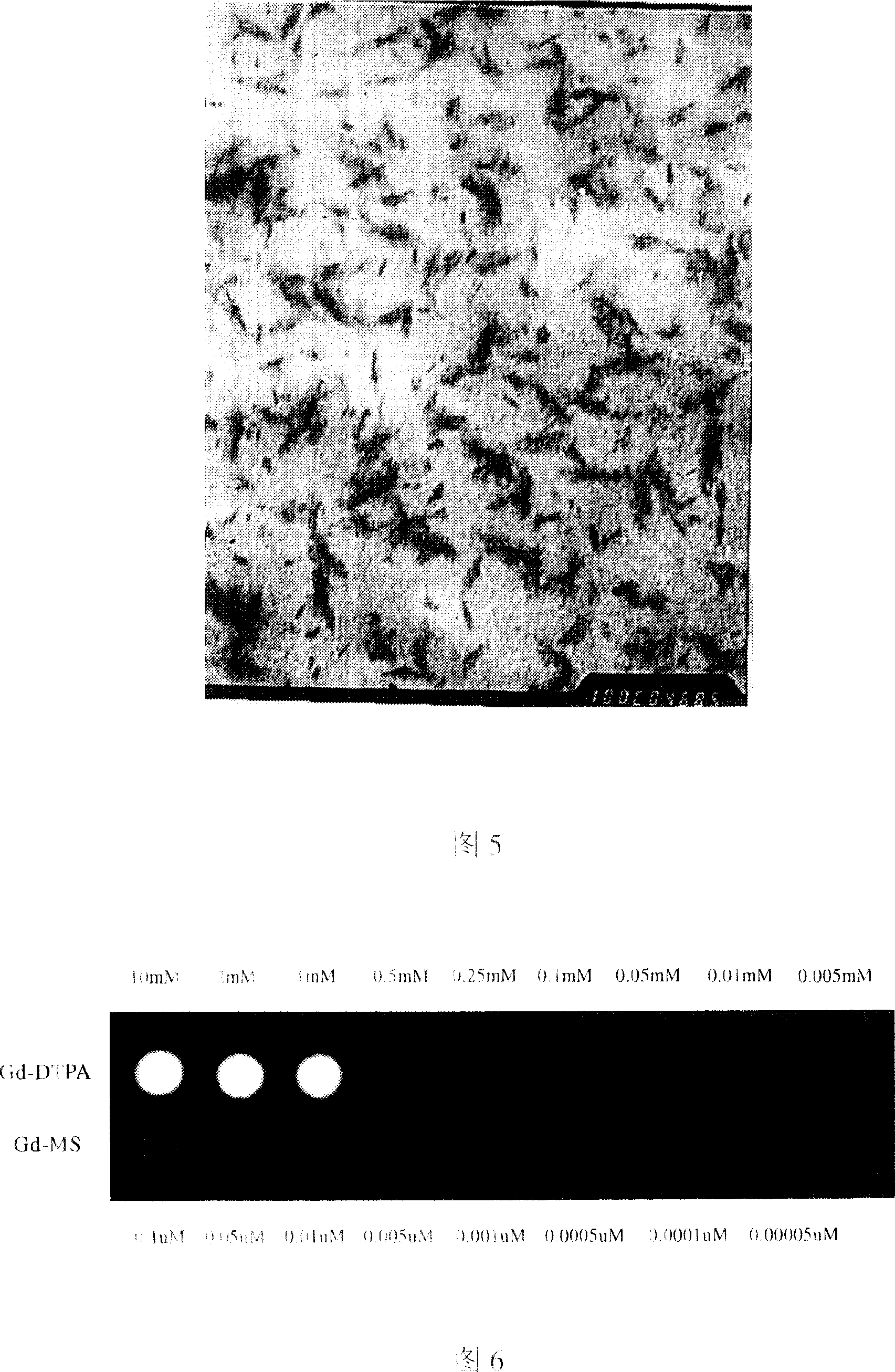

[0050] Example 3 Synthesis of gadolinium-doped nanocomposites using nonionic surfactant Pluronic F127 as a template and tetramethoxysilane as a silicon source

[0051] 2.8 millimoles of nonionic surfactant Pluronic F127 were dissolved in 30 milliliters of distilled water at 37 ° C, under ultrasonic vibration, Pluronic F127 was completely dissolved; then add 4 milliliters of concentrated hydrochloric acid (37%); continue to add 7 milliliters of mol tetramethoxysilane and 0.30 mmol GdCl 3 ·6H 2 O, the reaction was carried out for 7 minutes. Then, under ultrasonic vibration, the reaction solution was poured into 600 ml of 0.5 mol / L ammonia solution. The reaction was carried out for 35 minutes. The nanomaterials were collected by centrifugation (12000 rpm), dried at room temperature, and calcined at 400°C for 4 hours to obtain the gadolinium-doped nanocomposite material. The material is composed of particles with an average diameter of 36nm, and the average diameter of the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com