Process for preparing ultraviolet curable aqueous polyurethane resin

A water-based polyurethane and ultraviolet light technology, which is applied in the field of polyurethane coatings and adhesives, can solve the problems of no improvement in methyl ethyl ketone wiping performance, failure to improve methyl ethyl ketone wiping performance, and reduced hard segment content, so as to improve methyl ethyl ketone wiping performance and improve storage The effect of high stability and cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 36.7 grams of PTMG into a 500ml three-necked flask, dehydrate at 100°C for 1.5 hours, add 47.9 grams of IPDI, stir and react at 100°C for 2 hours, add 6.5 grams of hydrophilic chain extender DA, and stir at 90°C for 2 After one hour, add 22 grams of acetone, 45 grams of pentaerythritol tetraacrylate, 2.8 grams of p-methoxyphenol and 0.073 grams of dibutyltin dilaurate, and stir and react at 80°C for 2 hours, then add 6 grams of HEA, After stirring and reacting at 70°C for 2 hours, transfer the polyurethane resin into a high-speed shear disperser, add 5 grams of triethylamine at 800 rpm and 40°C, and react for 1 minute, then add 272 grams of water, and after 5 minutes , to obtain a UV-curable water-based polyurethane resin emulsion; transfer it to a rotary evaporator, remove acetone at 40°C and -0.1MPa vacuum conditions, and obtain a UV-curable water-based polyurethane resin.

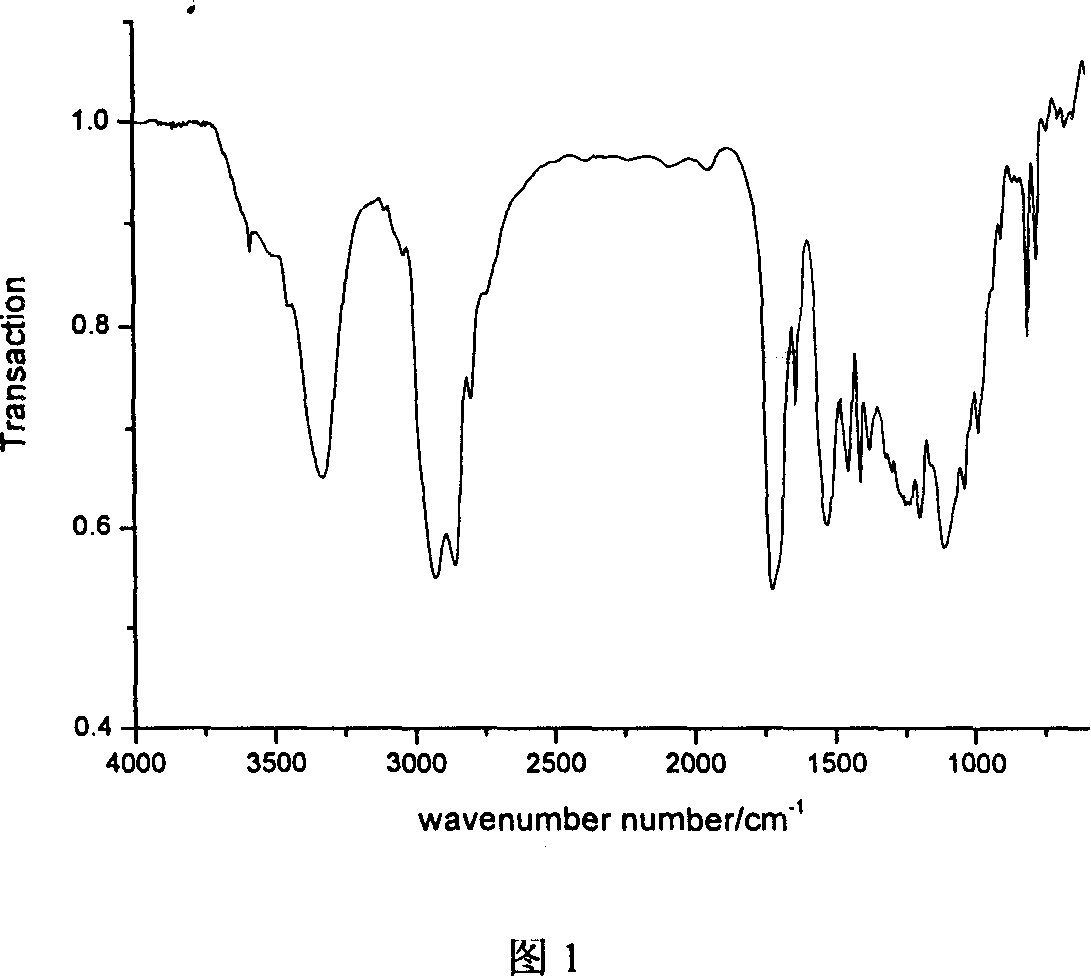

[0021] The structure of the polyurethane resin can be characterized by infrared spectrum. ...

Embodiment 2

[0024] Add 35.8 grams of PJ into a 500ml three-neck flask, dehydrate at 110°C for 1 hour, add 75.5 grams of MDI, stir and react at 80°C for 4 hours, add 12.3 grams of hydrophilic chain extender DA, and stir at 60°C for 4 After 1 hour, add 55 grams of methyl ethyl ketone, 36.6 grams of PEDA, 0.09 grams of hydroquinone and 0.018 grams of dibutyltin dilaurate, stir and react at 50 ° C for 4 hours, add 12 grams of HPA, and stir and react at 50 ° C for 3 hours , put it into a high-speed shear disperser, add 9.5 grams of triethylamine at 2000 rpm and 30 ° C, react for 2 minutes, add 418 grams of water, and after 1 minute, the UV-curable water-based Polyurethane resin emulsion; transfer to a rotary evaporator, remove acetone at 50°C and 0.09MPa vacuum to obtain a UV-curable waterborne polyurethane resin.

[0025] The structural characterization of the polyurethane resin is the same as in Example 1.

Embodiment 3

[0027] Add 95 kg of PCD and HTTP mixture into a 50L reactor, dehydrate at 120°C for 0.5 hours, add 64.8 kg of TDI, react at 90°C for 3 hours, add 8 kg of hydrophilic chain extender DA, at 80°C After reacting at ℃ for 1 hour, add 58.5 kg of acetone, 31.1 kg of TMPME, 3 kg of BHT and 0.069 kg of dibutyltin dilaurate. After stirring and reacting at 65°C for 3 hours, add 22.4 kg of PETA and react at 60°C for 2.5 hours. Transfer to a high-speed shearing disperser, add 6.5 kg of triethylamine at 4000 rpm and 20°C, react for 3 minutes, add 342 kg of water, and after 3 minutes, a UV-curable water-based polyurethane resin emulsion is obtained.

[0028] Transfer it to a solvent removal kettle, and remove acetone under 60°C and 0.08MPa vacuum conditions to obtain a UV-curable water-based polyurethane resin. The structural characterization of the polyurethane resin is the same as in Example 1.

[0029] If the other conditions of this embodiment remain unchanged, and PCD or HTTP is replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com