Hot sprayed zinc-aluminium alloy wire rod and its preparing method

A zinc-aluminum alloy and thermal spraying technology, which is applied in the direction of coating, molten spraying, metal material coating technology, etc., to achieve the effects of simple equipment, improved precision, excellent corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The weight percentages of the main elements of the wire are shown in Table 1.

[0022] Table 1 Example 1 Wire composition example (wt%)

[0023] Al

Mg

Ti

B

Fe+Si+Cu

Zn

15%

0.50%

0.50%

0.05%

≤1.00%

margin

[0024] preparation:

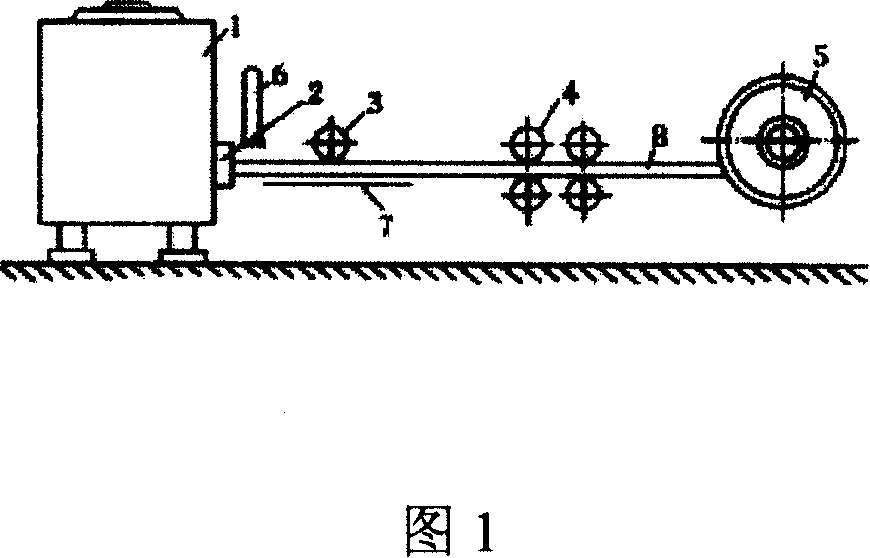

[0025] A schematic structural diagram of the horizontal continuous casting equipment used in the present invention is shown in Figure 1 . Among them: 1 is the heat preservation crystallization furnace; 2 is the crystallizer; 3 is the pressing roller; 4 is the pulling roller; 5 is the coiling device; 6 is the cooling water pipe;

[0026] 1) Preheat the crucible of the melting furnace to dark red, add zinc ingots with a mass fraction of 90%, then add aluminum ingots, heat and melt until the melt temperature reaches 923K or more, use a mass fraction of 0.1 ~ 0.3% of the refining agent ( In this embodiment, 0.2% zinc chloride is used for refining, the remaining zinc ingot...

Embodiment 2

[0031] The difference from Example 1 is: the wire composition is: Al, 20%; RE, 0.5%; impurities, less than 1%; the balance Zn. The copper mold is used to cast the alloy wire wool, the temperature of the alloy liquid in the furnace is stable at 60K higher than the melting point, the casting speed is 0.015m / s, and the cooling water pressure is 0.15×10 5 Pa, the outlet water temperature is 308K. The rough wire is subjected to homogenization annealing treatment at 513K for 3.0 hours, and then drawn and reduced to φ2.00 for 8 times. -0.10 +0.00 mm of zinc-aluminum alloy wire products, and coiled into a circle.

Embodiment 3

[0033]The difference from Example 1 is: the wire composition is: Al, 10%; RE, 0.06%; Mg, 0.03%; impurities, less than 1%; the balance Zn. The copper mold is used to cast the alloy wire wool. The temperature of the alloy liquid in the furnace is stable at 80K higher than the melting point, the casting speed is 0.015m / s, and the cooling water pressure is 0.12×10 5 Pa, the outlet water temperature is 308K. The rough wire was subjected to a homogenization annealing treatment at 493K for 3.0 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com