Jitter compensation plasma display

A plasma display, dielectric technology, used in inorganic insulators, ceramics, solid cathode components, etc., can solve the problems of limited increase in dielectric constant, unbearable internal voltage, increased electrostatic capacity, etc., to prevent jitter and low temperature. /High temperature false discharge, improve brightness and efficiency, increase electrostatic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below through various specific embodiments.

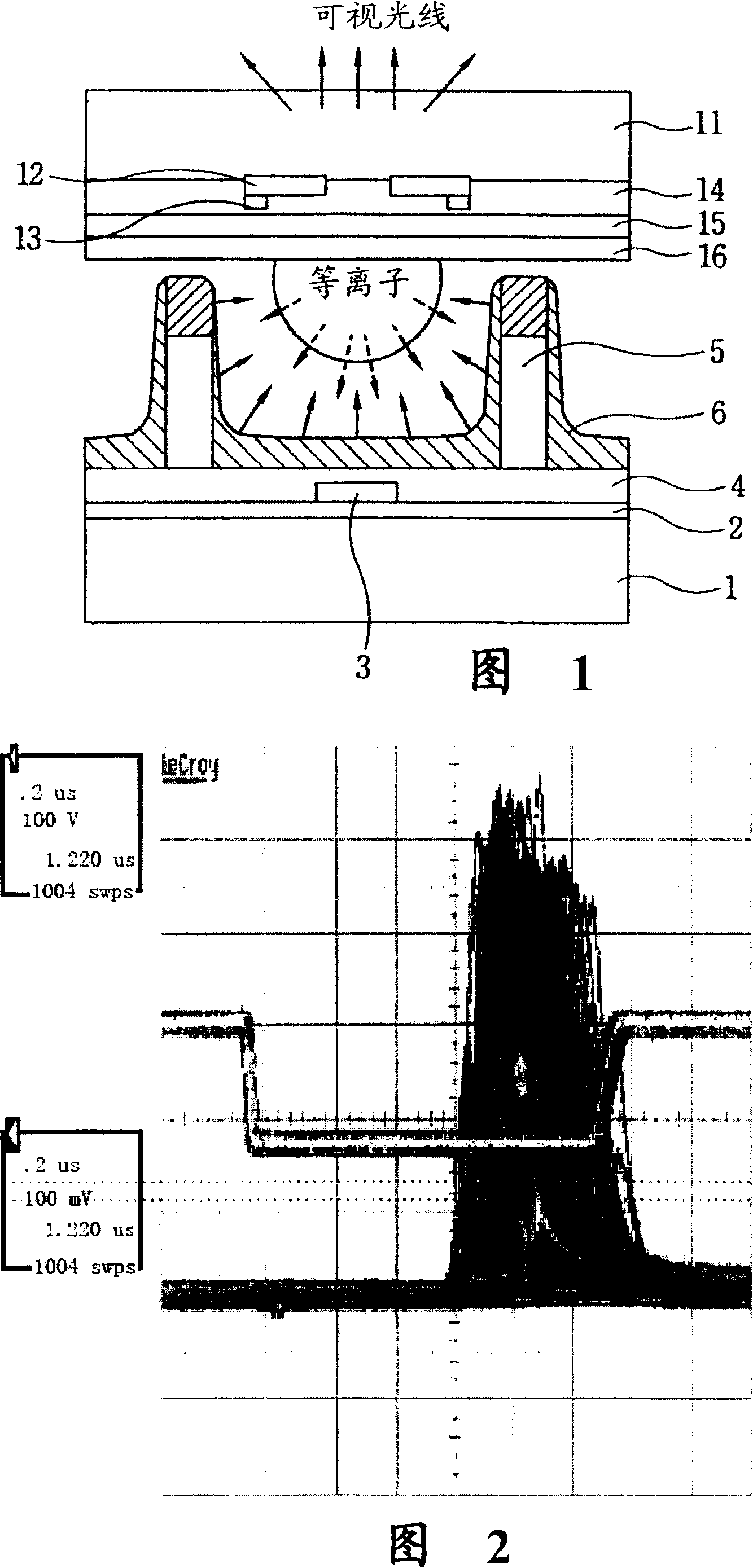

[0032] The present invention uses ceramic materials with high dielectric constant and high insulation resistance to increase the electrostatic capacity on the upper / lower plate dielectrics constituting the PDP element, and on the other hand, applies the dielectric with high internal pressure characteristics to the PDP element , in order to improve the resistance of the discharge voltage. Not only that, but ferroelectric ceramic materials are applied to the phosphor, which can induce some reflection of visible light while increasing the electrostatic capacity to improve luminance and efficiency. The above-mentioned increase in electrostatic capacity means reduction of jitter phenomenon, and can also alleviate low-temperature / high-temperature discharge.

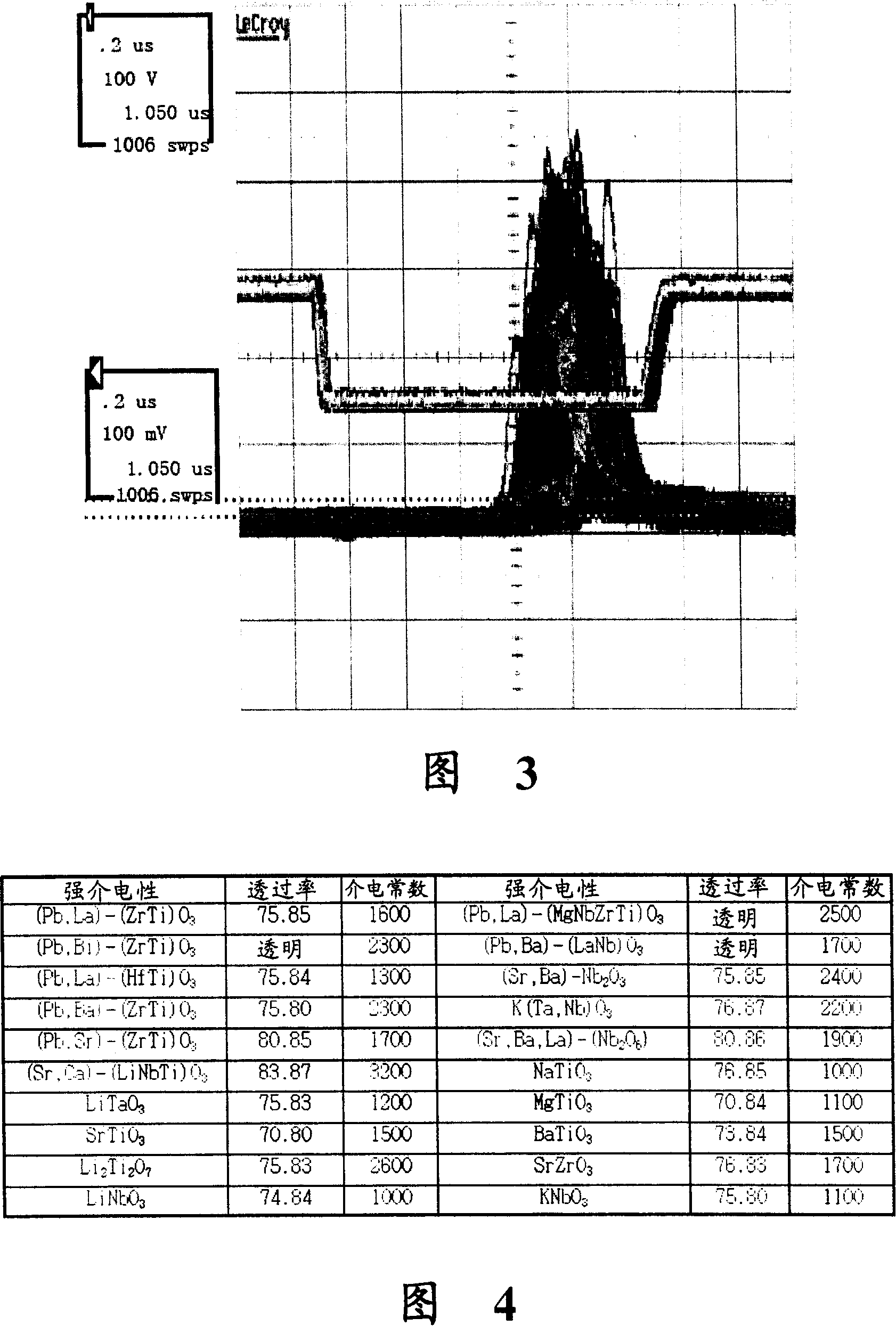

[0033] Because the ferroelectric ceramic material that can be applied in the present invention is used to improve the dielect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com