Process and method for recovery of halogens

A halogen and halide technology, applied in the field of corresponding halogen solution or solid deposit collection, can solve the problems of heat generation, consumption of electrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

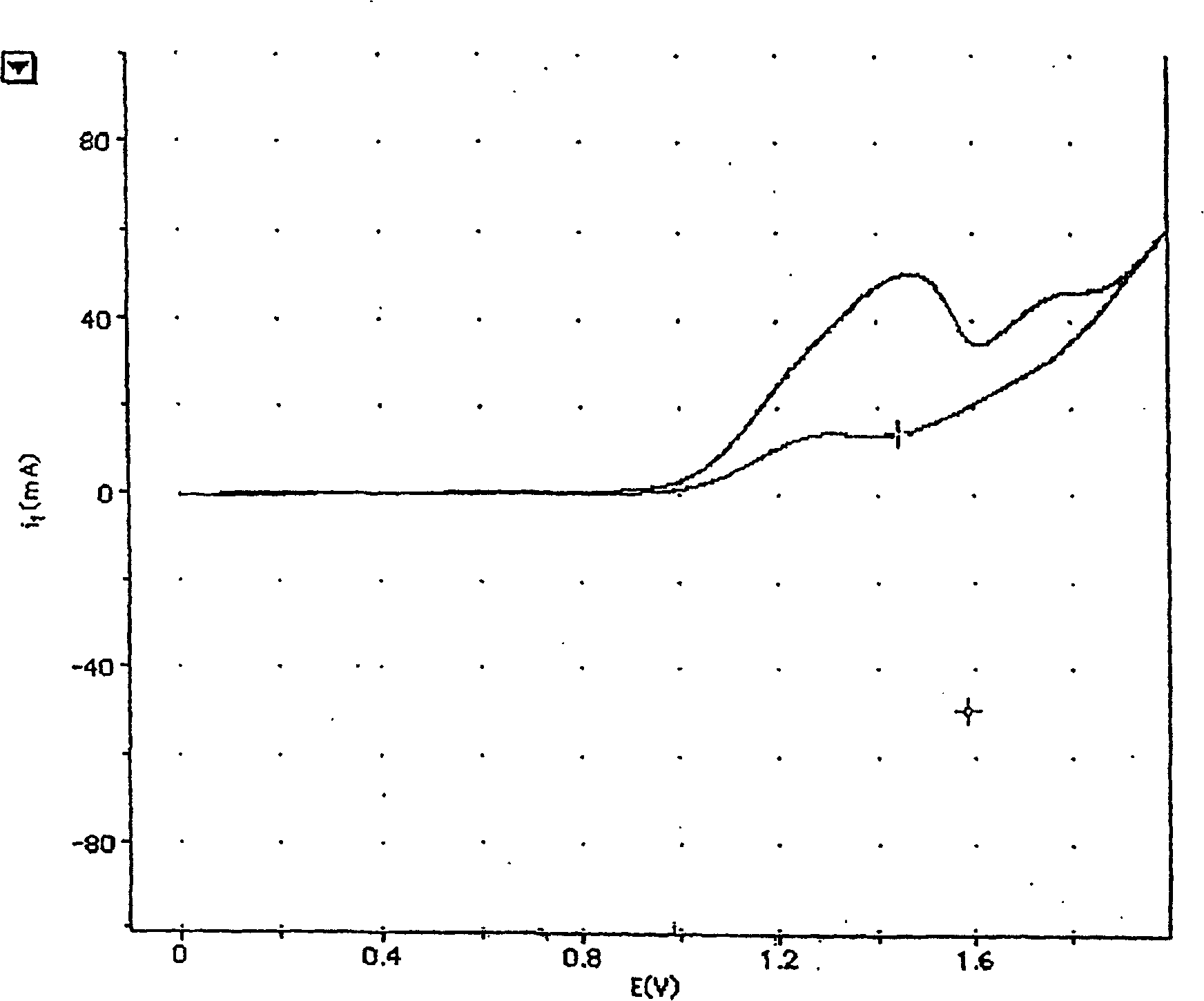

[0157] For a 100mg / ml iodide solution, the electrolytic extraction potential added to the stainless steel electrode is determined by cyclic voltammetry scanning of the electrode in the solution. To this end, the potential is increased from 0 volts to 2 volts at a rate of 100 mv / s, and the current is measured at the same time. The resulting cyclic voltammogram is as image 3Shown. Its trajectory shows the characteristic wave of current. The electrolytic extraction process takes place at the apex of this wave. The best potential can be selected from this trajectory, that is, the lowest potential when the current reaches or approaches the maximum. In this example it is 1.5v.

example 2

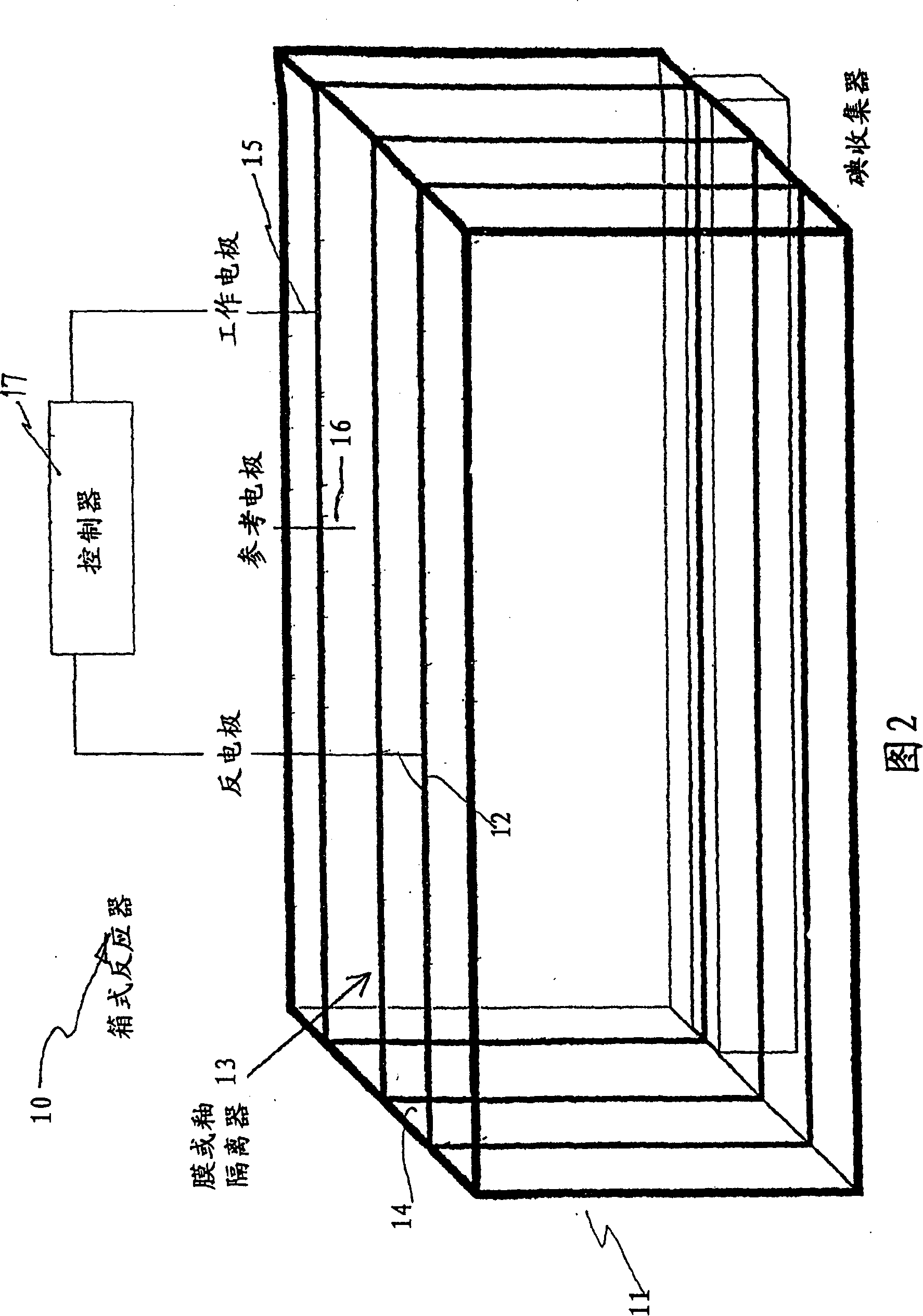

[0159] The following example illustrates one method of obtaining electro-deposited iodine (EDI). The electrolytic extraction of iodine is accomplished with a three-electrode system. A stainless steel working (Grade18 / 8) electrode consists of three separate 40mm discs mounted on the glaze. The reference electrode is a commodity Ag / Ag + The electrode and the counter electrode are a stainless steel disc. The electrolytic cell consists of a 120ml glass container, and there is a sinter with a porosity of 5 at the bottom. Put 100ml of 0.1M sulfuric acid in 100mgml -1 The potassium iodide solution is added to the electrolytic cell. The solution was stirred with magnetic stirring beads coated with Teflon (polytetrafluoroethylene). Then put the electrolytic cell into a large pan, which contains about one liter of 0.1MH 2 SO 4 . Then the anode electrode and the reference electrode are immersed in an acidic potassium iodide solution and the counter electrode is placed in an outer container f...

example 3

[0161] Use the same method as in Example 2, but use Nafian membrane instead of glass glaze as a separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com