A kind of living/controllable radical polymerization method of water-soluble monomer

A technology of water-soluble monomers and polymerization methods, which is applied in the field of active/controllable free radical polymerization of water-soluble monomers in water, can solve the problems of poor controllability of polymerization reactions, and achieve difficult decomposition, increased reaction efficiency, and low reaction components little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

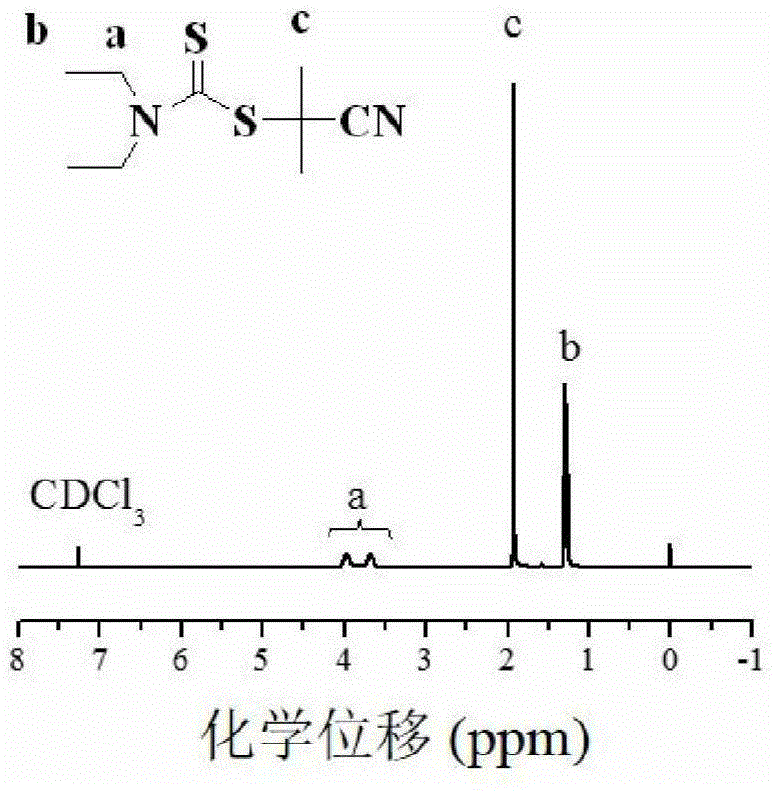

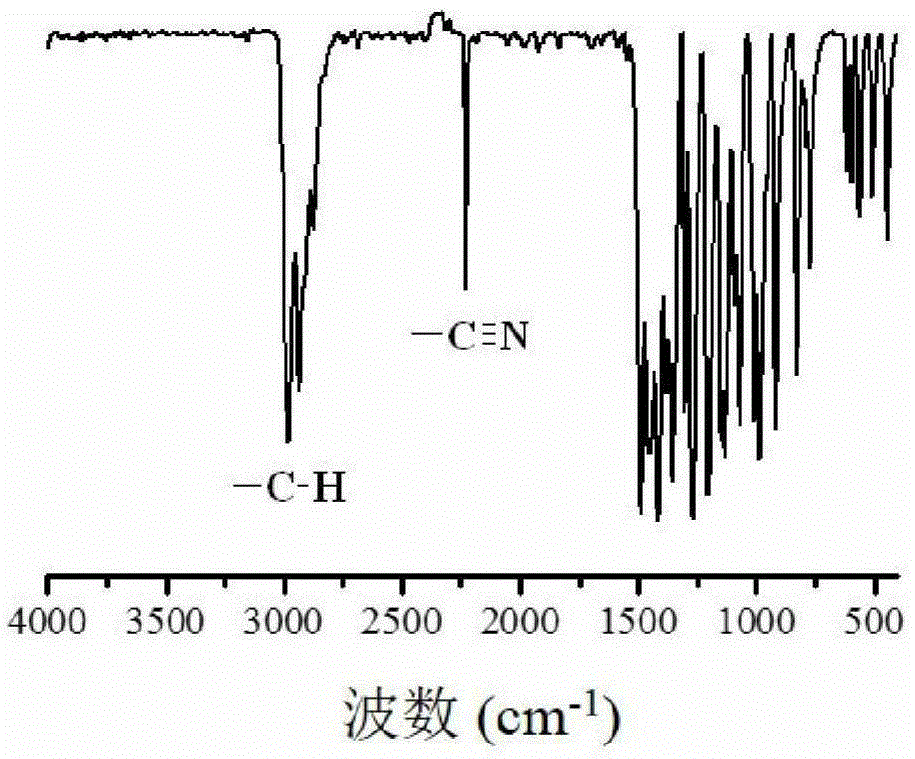

[0029] Example 1: Preparation of 1-cyano-1-methylethyl N,N-diethyldithiocarbamate.

[0030] In a three-neck round bottom flask, add tetraethylthiuram disulfide (TETD) (9.03 g, 0.030 mol), azobisisobutyronitrile (AIBN) (7.5 g, 0.045 mol) and 100 mL of toluene, and flush with nitrogen Deoxygenation was performed for 30 minutes, followed by reaction at 55° C. for 65 hours in a nitrogen atmosphere. The white precipitate was removed by filtration, and the toluene was removed by rotary evaporation to obtain a crude product. The crude product was distilled under reduced pressure at 107~115°C and 1mmHg to obtain a light yellow product, which 1 H-NMR (400MHz, CDCl3 ) spectrum and IR (KBr) spectrum such as figure 1 and figure 2 shown.

Embodiment 2

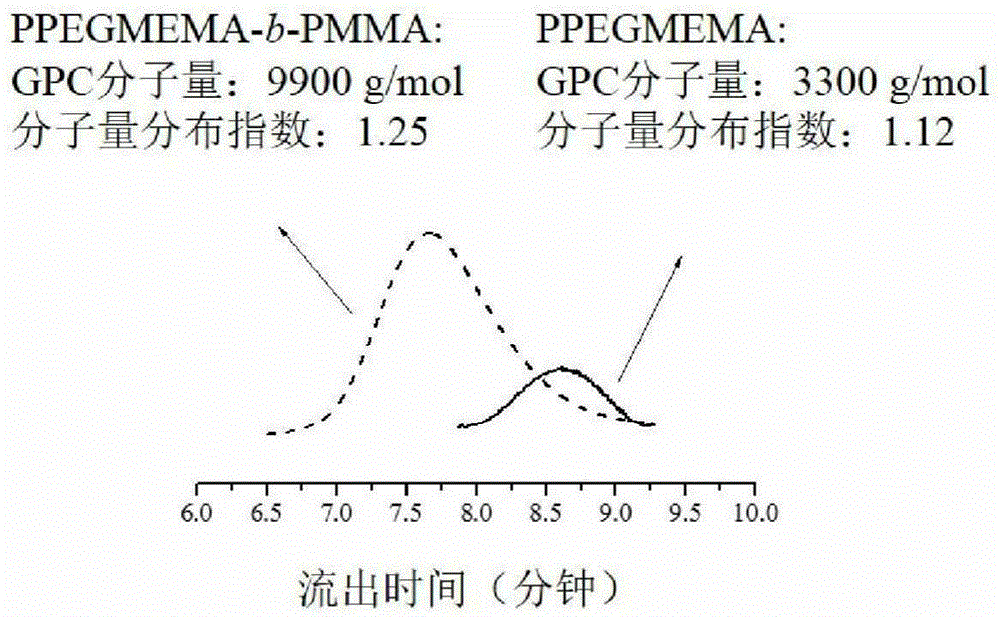

[0031] Example 2: Polymerization of polyethylene glycol monomethyl ether methacrylate at 70°C.

[0032] With 3mL water as solvent, PEGMEMA (1mL, 2.28mmol), Cu(OAc) 2 (2.2mg, 0.012mmol) and MANDC (5.1mg, 0.024mmol) were added to a 5mL ampoule, nitrogen gas was passed through the ampoule for 20 minutes to remove the oxygen in it, the mouth of the bottle was melted and sealed in time, and the ampoule was placed in Polymerization was carried out in an oil bath at 70°C. After reacting for 2 hours, take it out and put it in ice water, open the ampoule, freeze-dry the reaction solution to remove water, dissolve it in THF, precipitate it in about 200mL of n-hexane, pour off the upper solution after standing still, and dry it. to obtain the desired polymer.

Embodiment 3

[0033] Example 3: Polymerization of hydroxyethyl methacrylate at 70°C.

[0034] With 1.5mL water and 1.5mL methanol as solvent, HEMA (1mL, 8.25mmol), Cu(OAc) 2 (8.0mg, 0.044mmol), MANDC (18.5mg, 0.085mmol) were added to a 5mL ampoule, and neon gas was passed through the ampoule for 20 minutes to remove the oxygen in it, and the mouth of the bottle was melted and sealed in time, and the ampoule was placed Polymerization was carried out in an oil bath at 70°C. After reacting for 2 hours, take it out and put it in ice water, open the ampoule bottle, freeze-dry the reaction solution to remove water, dissolve it in DMF, precipitate it in about 200mL of n-hexane, let it stand, filter it with suction, and dry it to get the Polymer is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com