Dedicated nano compound agglomerate for outdoors lamp and its preparation method

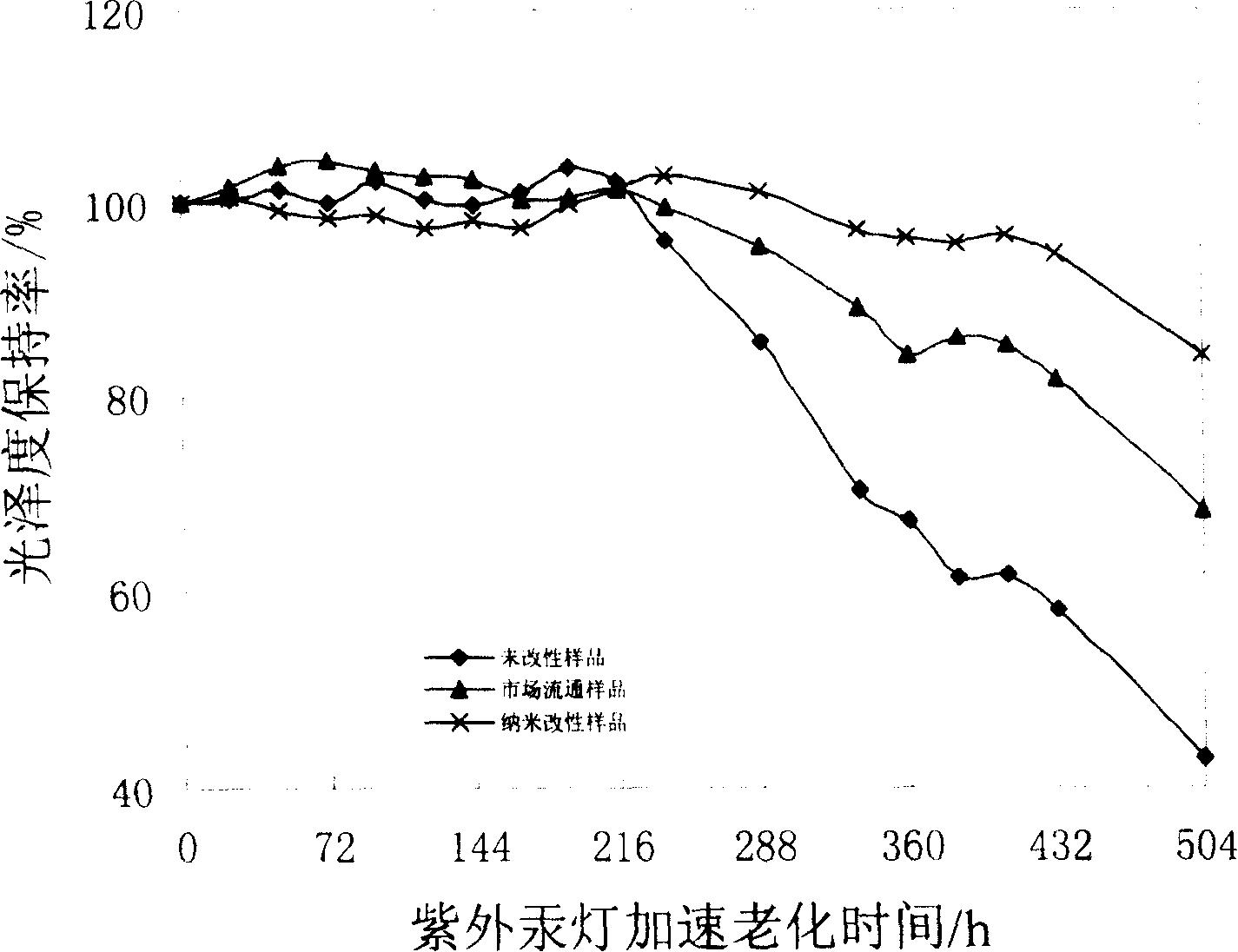

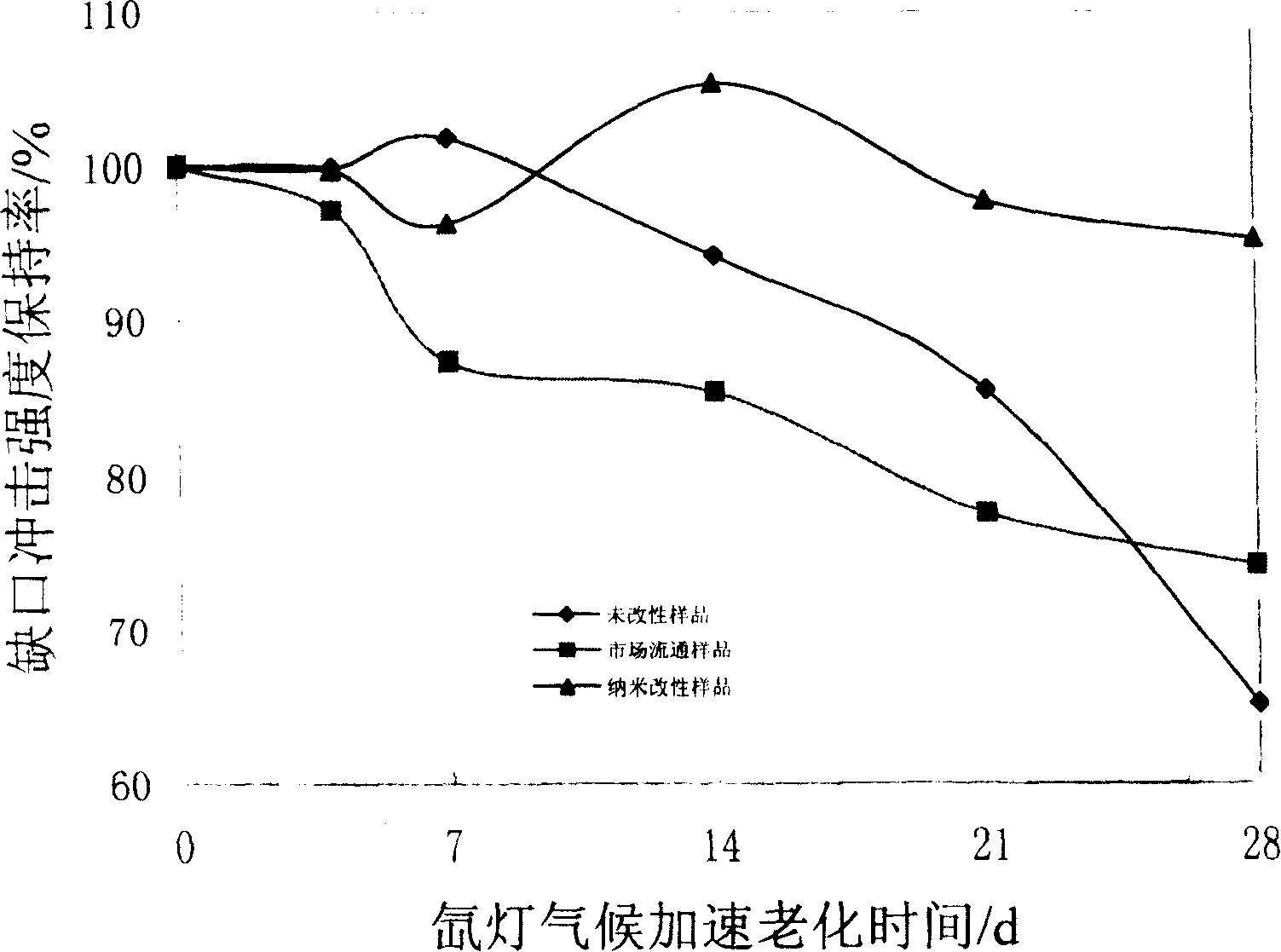

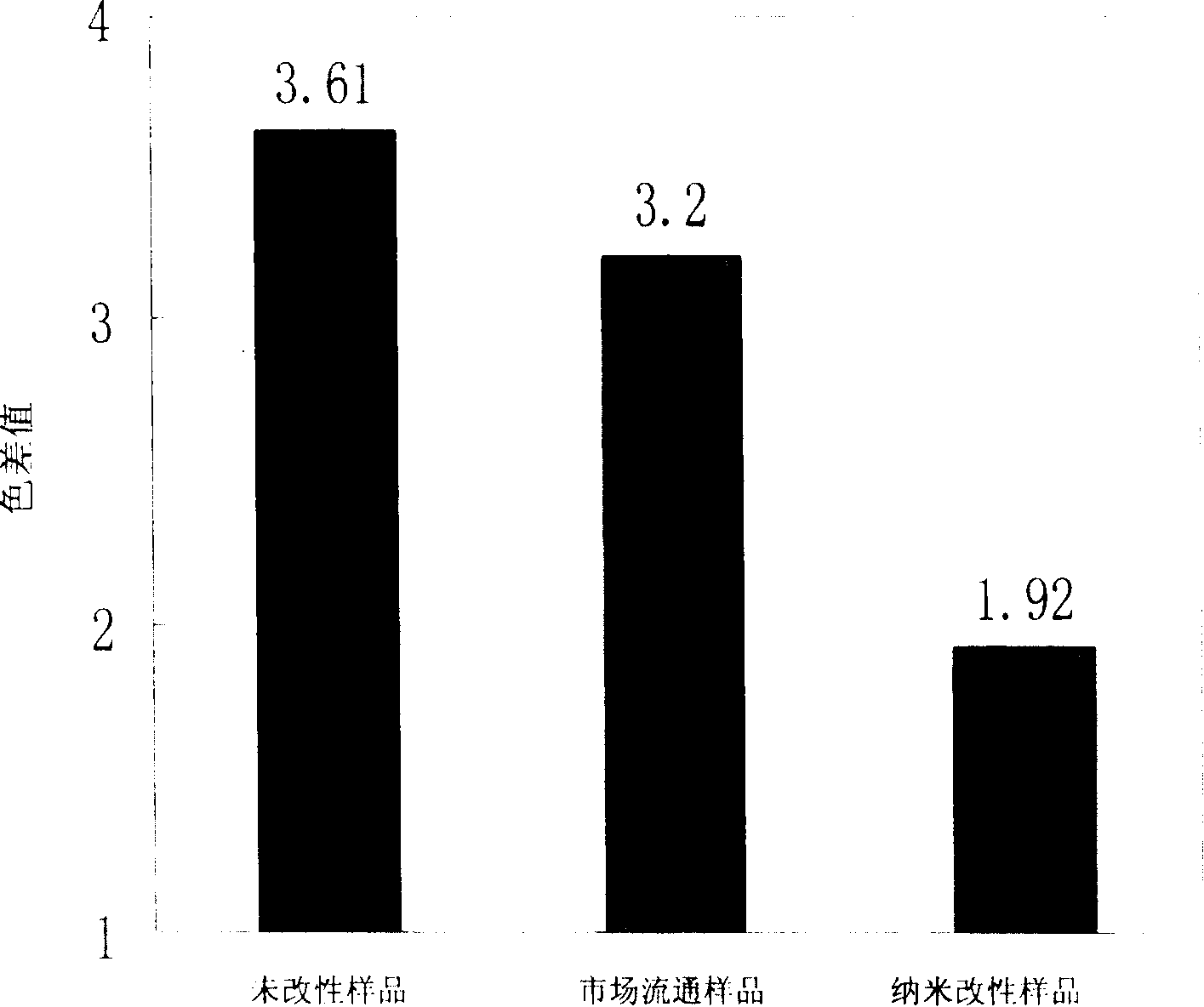

A nano-composite, outdoor lighting technology, applied in the field of outdoor lighting materials, can solve the problem of not finding a special nano-composite masterbatch for outdoor lighting and other problems, achieve good thermal processing stability, reduce fracture reaction speed, improve dispersion and light stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation of embodiment 1 masterbatch of the present invention

[0063] Table 1

[0064] Recipe Components

Nylon 6

Rutile nano-TiO 2

Irganox245

Ultranox626

Tinuvin770

Weight / (kg)

95.5

0.5

0.1

0.3

0.1

3.5

[0065] a. Take the materials as shown in Table 1;

[0066] b. Inorganic nanomaterials, rutile nano-TiO 2 Dry at 110°C for 3 hours, and vacuum-dry the polymer resin at 120°C for 15 hours;

[0067] c, the rutile nano-TiO 2 Pre-mix with polymer resin, inorganic fillers, and organic additives in a mixer for 4-8 minutes, and the pre-mixing speed is 1000-1500rpm;

[0068] d. Melt and extrude the pre-mixed material with twin-screw extrusion equipment with an aspect ratio greater than 40 at 230-290°C, the screw speed is 80-200rpm, and then cool the extruded material with water at a temperature of 70-160rpm Granulation is carried out at a rotating speed to form a w...

Embodiment 2

[0069] The preparation of embodiment 2 masterbatch of the present invention

[0070] Table 2

[0071] Recipe Components

Nylon 66

Rutile nano-TiO 2

Irganox245

Ultranox626

Tinuvin770

Titanium dioxide

Weight / (kg)

96.7

0.3

0.1

0.3

0.1

2.5

[0072] Get material such as table 2, preparation method is with embodiment 1;

[0073] The rutile nano-TiO used in this embodiment 2 It is rutile nano-TiO 2 Obtained by inorganic coating and organic treatment, the specific preparation method steps are as follows:

[0074] Inorganic coating process:

[0075] The mass content is 10% rutile nano-TiO 2 The suspension was sanded for 90 minutes, and then the suspension was made into nano-TiO 2 For slurry with a content of 2% to 10%, sodium silicate and sodium metaaluminate are used as silicon-coated and aluminum-coated additives, and sulfuric acid solution with a mass concentration of 10% is used as an auxiliar...

Embodiment 3

[0078] The preparation of embodiment 3 master batches of the present invention

[0079] table 3

[0080]

[0081] Get material such as table 3, preparation method is the same as embodiment 2; The rutile type nano-TiO used in this embodiment 2 With embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com