Nanometer material modified polyethylene agricultural film and its preparing method

A technology of nano-materials and agricultural films, applied in the field of nano-materials, can solve the problems of complex process, reduction, easy agglomeration and anti-aging effect of nano-SiO2, and achieve the effect of simple preparation method, reduction of environmentally harmful products, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the first step, 1 part of nano-TiO with an average particle size of 20-30nm 2 After drying at 100°C for 4 hours, 0.5 parts of dried nano-TiO 2 Grinding and mixing with 0.5 parts of silane coupling agent in a ball mill at a high speed in a ratio of 1:1 for 20 minutes to complete surface treatment and compound into an inorganic nanocomposite material;

[0038] In the second step, dry the inorganic nanocomposite material at 100°C for 3 hours, mix 0.2 parts of inorganic nanocomposite material with 98.6 parts of polyethylene resin, 0.1 part of tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, 0.3 parts of tris(2,4-di-tert-butylphenyl)phosphite, 0.2 parts of 2-(2'-hydroxy-3',5' -Di-tert-phenyl)-5-chlorinated benzotriazole, 0.1 part of oleic acid amide, 0.5 part of polyethylene wax were premixed for 10 minutes, and the premixing speed was 1300rpm;

[0039] The third step is to process the pre-mixed materials on the extruder according...

Embodiment 2

[0041]Example 2: The specific preparation method is the same as in Example 1, and the material ratio and its ratio are as follows: 98.6 parts by weight of polyethylene, 0.16 parts by weight of titanium dioxide powder, 0.04 parts by weight of silicon dioxide powder, and 0.1 parts by weight of titanate coupling agent. Parts by weight, 0.1 parts by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.3 parts by weight of tris (2,4-di-tert-butylphenyl) phosphite 0.1 part by weight of 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, 0.1 part by weight of oleic acid amide, and 0.5 part by weight of polyethylene wax.

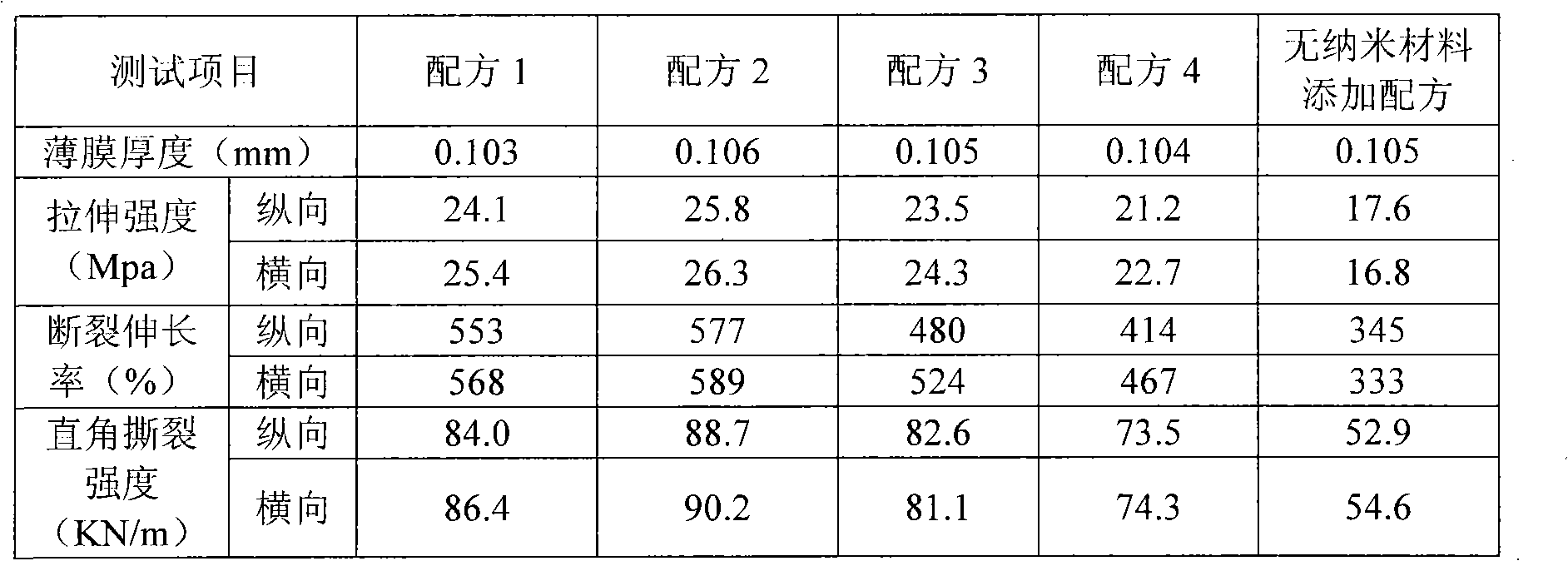

[0042] According to GB / T 13022-91 Plastics—Test method for tensile properties of films, QB / T1130-91 Test method for right-angle tear properties of plastics, the film is made into a standard sample, and then according to GB / T 16422.3-1999 Plastic laboratory light source Exposure test method part 3: Fluorescent ultraviolet lamp, using...

Embodiment 3

[0043] Embodiment 3: The specific preparation method is the same as in Example 1, and the material ratio is as follows: 91.5 parts by weight of polyethylene, 0.5 parts by weight of titanium dioxide powder, 0.5 parts by weight of silicon dioxide powder, 0.5 parts by weight of titanate coupling agent, four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] 0.3 parts by weight of pentaerythritol ester, 0.7 parts by weight of tris (2,4-di-tert-butylphenyl) phosphite, 4- 1 part by weight of benzoyloxy-2,2,6,6-tetramethylpiperidine, 1 part by weight of oleic acid amide and 4 parts by weight of polyethylene wax.

[0044] According to GB / T 13022-91 Plastics—Test method for tensile properties of films, QB / T1130-91 Test method for right-angle tear properties of plastics, the film is made into a standard sample, and then according to GB / T 16422.3-1999 Plastic laboratory light source Exposure test method part 3: Fluorescent ultraviolet lamp, using a fluorescent ultraviolet lamp climat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com