Electrode bar for grounding

A technology of grounding electrodes and rods, applied in the direction of connecting contact materials, etc., can solve the problems of difficult installation and construction, scratches on the copper layer or insufficient mechanical strength, etc., and achieves the effect of good airtightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

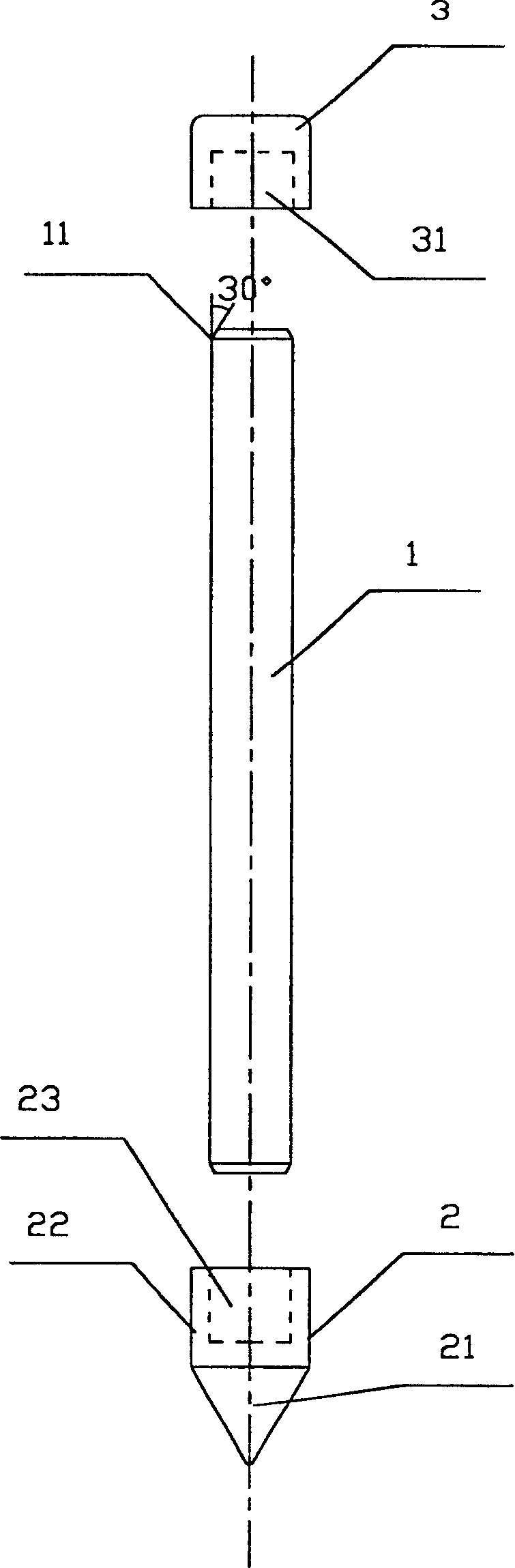

[0039] Example 1, see figure 1 , The figure shows a grounding electrode rod, which includes a cylindrical rod body 1, the rod body is a copper-plated steel rod, copper-clad steel rod or other metal rod body, set at one end of the rod body 1 There is a ground-boring safety cone 2, and a hammer condom 3 is provided at the other end. The hammered condom 3 is cylindrical, one end of which is opened with a cylindrical first cavity (cavity A) 31 that is adapted to the end of the rod body 1; it has the same shape as the end of the cylindrical rod body 1 For adaptation, the inner diameter of the first cavity (cavity A) 31 of the hammer condom 3 and the outer diameter of the end of the rod 1 are transitional fit, and the gap is 0.05-0.10 mm. The safety cone 2 for earth boring includes a cone-shaped head 21 and a cylindrical tail 22 for connecting with the rod body 1. The end surface of the cylindrical tail part 22 is provided with a second end that is adapted to the other end of the rod b...

Embodiment 2

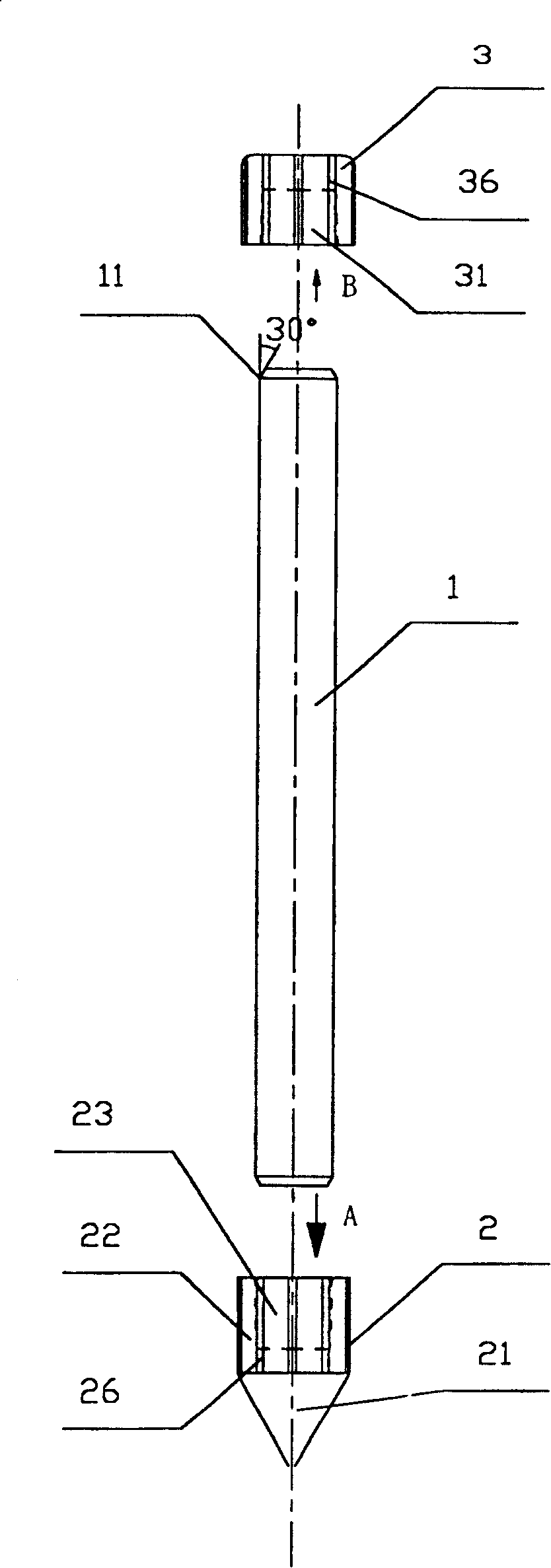

[0040] Example 2, see figure 2 , 2A And 2B, the figure shows a grounding electrode rod. The difference from the previous embodiment is that the second cavity (cavity B) 23 of the ground-boring safety cone 2 is a slightly tapered cone. The taper of the hole is 1:30, and the taper hole 23 is more closely connected with the end of the cylindrical rod 1. Similarly, in order to make the connection between the hammered condom 3 and the rod 1 tight, the first cavity (cavity A) 31 of the hammered condom may be a slightly tapered cone-shaped hole with a taper of 1:30. Another difference is that the outer surfaces of the drill safety cone 2 and the hammer condom 3 are respectively provided with a number of second ditch (earth ditch B) 26 and first ditch 36, the distribution density of which is per centimeter of the circumference Length 1-25; in this embodiment, there are 10 second earthen ditch (earth ditch B) 26 and first earthen ditch (earth ditch A) 36 respectively. The first earthen di...

Embodiment 3

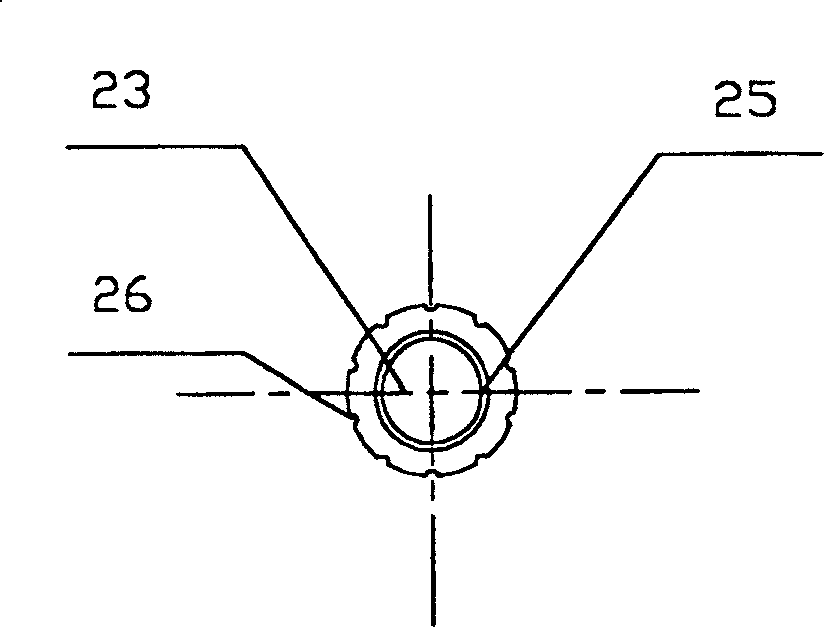

[0041] Example 3, see image 3 , The figure shows a grounding electrode rod. The difference from implementation 1 is that the safety cone 2 and the hammer condom 3 can be threaded to the two ends of the rod body 1, and the safety cone 2 is in the cylindrical shape. The second cavity (cavity B) 23 of the tail 22 and the first cavity (cavity A) 31 of the hammer condom are screw holes 25 and 32. The two ends of the rod body 1 are provided with external threads 14 And 12; another difference is that: the hammer condom 3 is a hexagonal prism shape, that is, a hexagonal nut with one end closed, the columnar tail 22 of the ground boring safety cone 2 is a hexagonal prism shape, and The cone-shaped head 21 is in the shape of a hexagonal pyramid, see Figure 3A with 3 B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com