Method for preparing TiC/Ni3Al intermetallic compound based surface composite coating

An intermetallic compound and surface compounding technology, applied in mechanical equipment, heat exchange equipment, belts/chains/gears, etc., can solve the problems of limited size and compound position, large equipment investment, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of TiC(15wt%) / Ni 3 Al coating

[0022] Ti powder (500 mesh) with purity ≥99.8%, graphite powder (particle size ≤30μm) with purity ≥99.85%, Al powder (300 mesh) with purity ≥98% and Ni powder (200 mesh) with purity ≥99% , according to Ti, C, Al, and Ni as the molar ratio of 1:1 and 1:3 respectively, Ti, C accounted for 15% of the total amount of mixed powder, mixed powder on a planetary ball mill for 16 hours, and the ball-to-material ratio was 3 : 1. The evenly mixed powder is pressed into a φ20mm×2mm compact on a 10-ton press, with a density of 55%, and dried at 150°C for 5 hours in a vacuum state, and then pasted with 3% PVA aqueous solution to dry the prefabricated block in air The 12h sand mold wall, after preheating at 400°C for 30min, poured molten steel at a temperature of 1600°C, reaction compounding and densification occurred, and 15wt% TiC / Ni was obtained after solidification 3 Composite coatings on Al intermetallic-based surfaces.

Embodiment 2

[0024] Preparation of TiC(35wt%) / Ni 3 Al coating

[0025] Ti powder (300 mesh) with purity ≥99.8%, graphite powder (particle size ≤30μm) with purity ≥99.85%, Al powder (300 mesh) with purity ≥98% and Ni powder (200 mesh) with purity ≥99% , according to Ti, C, Al, Ni as the molar ratio of 1:1 and 1:3 respectively, Ti, C accounted for 35% of the total amount of mixed powder, mixed powder on a planetary ball mill for 20h, the ball-to-material ratio was 3 : 1. The evenly mixed powder is pressed into a compact of φ20mm×6mm on a 10-ton press, with a density of 58%, and dried under vacuum at 150°C for 5 hours, and then pasted with 3% PVA aqueous solution on the air-dried 12h The sand mold wall, after preheating at 400°C for 30 minutes, poured molten steel at a temperature of 1580°C, reaction compounding and densification occurred, and 35wt% TiC / Ni was obtained after solidification 3 Composite coatings on Al intermetallic-based surfaces.

Embodiment 3

[0027] Preparation of TiC(50wt%) / Ni 3 Al coating

[0028] Ti powder (300 mesh) with purity ≥99.8%, graphite powder (particle size ≤30μm) with purity ≥99.85%, Al powder (300 mesh) with purity ≥98% and Ni powder (200 mesh) with purity ≥99% , according to Ti, C, Al, and Ni as the molar ratio of 1:1 and 1:3 respectively, Ti and C account for 50% of the total amount of mixed powder, and mix the powder on a planetary ball mill for 24 hours, and the ball-to-material ratio is 3 : 1. The evenly mixed powder is pressed into a compact of φ20mm×10mm on a 10-ton press, with a density of 52%, and dried under vacuum at 150°C for 5 hours, and then pasted with 3% PVA aqueous solution on the air-dried 12h The sand mold wall, after preheating at 400°C for 30 minutes, poured molten steel at a temperature of 1550°C, reaction compounding and densification occurred, and 50wt% TiC / Ni was obtained after solidification 3 Composite coatings on Al intermetallic-based surfaces.

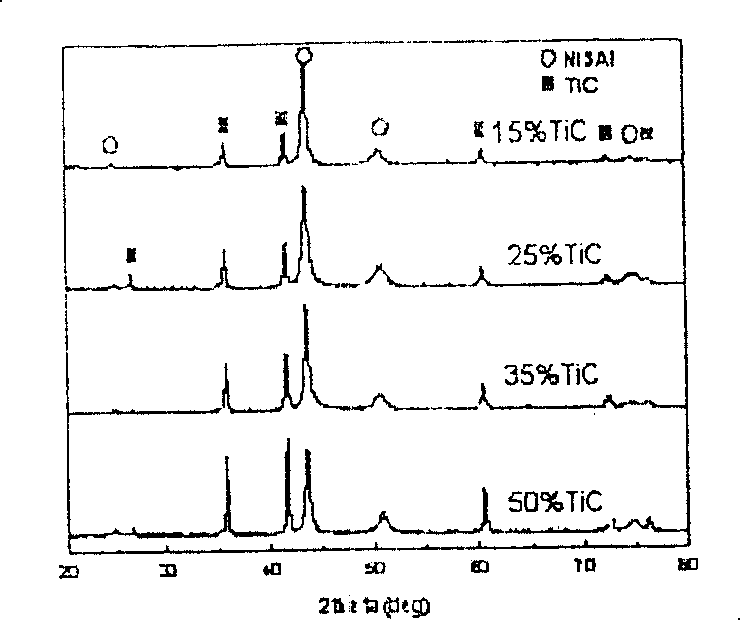

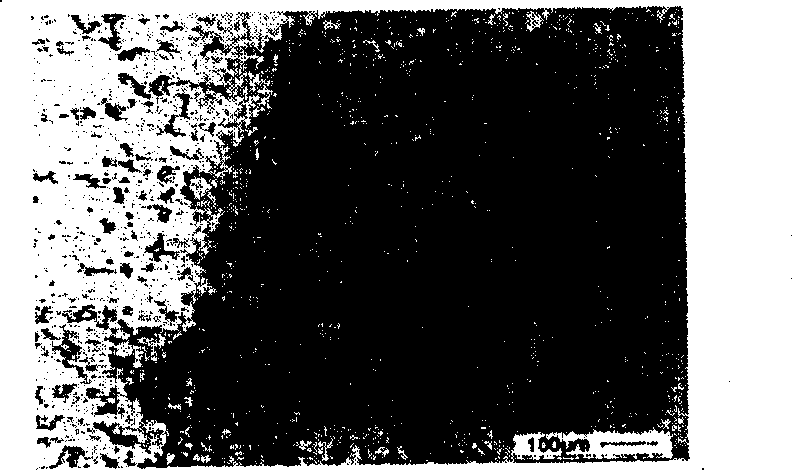

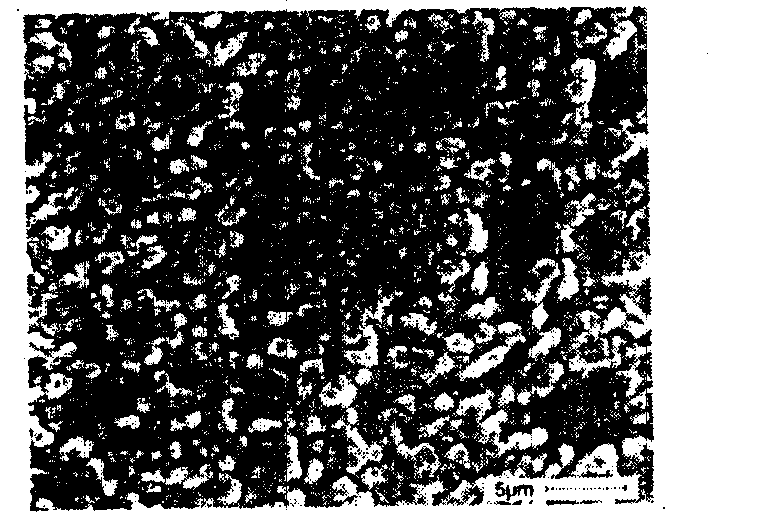

[0029] Depend on Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com