Advanced lighting system for micro light carving method

一种照明系统、照明光学系统的技术,应用在微光刻曝光设备、图纹面的照相制版工艺、光学等方向,能够解决曝光光学部件可变相干性等问题,达到简单光学部件的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

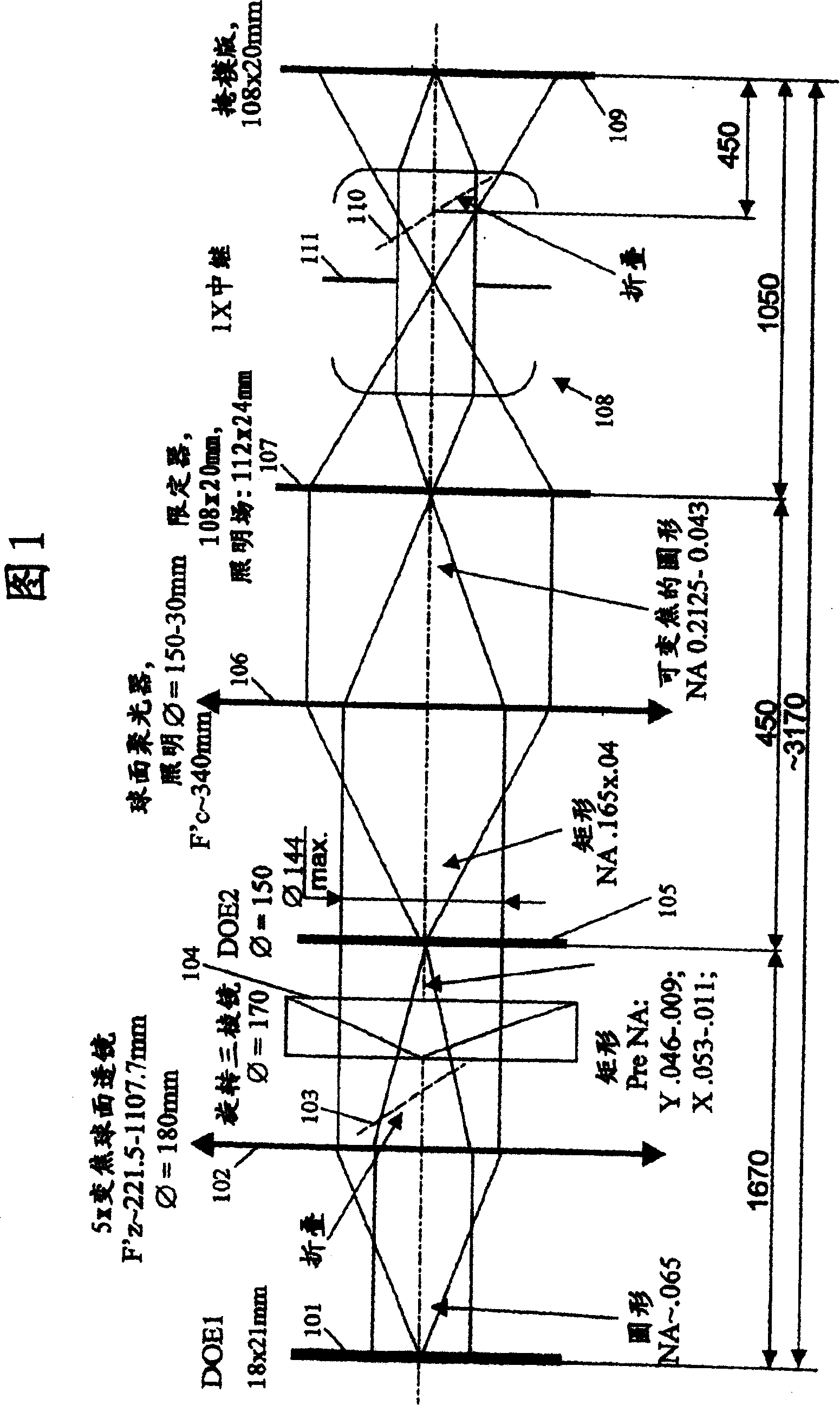

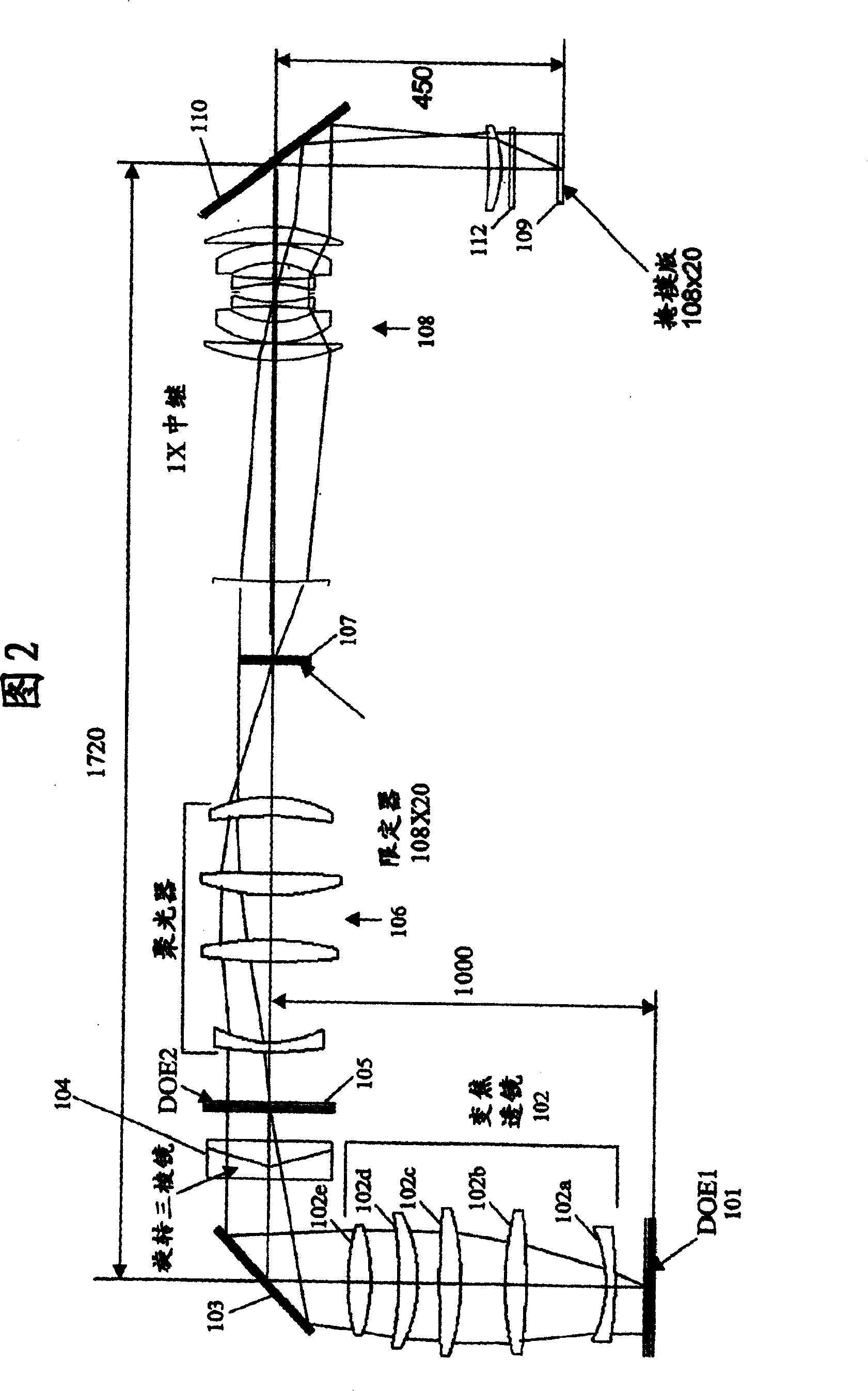

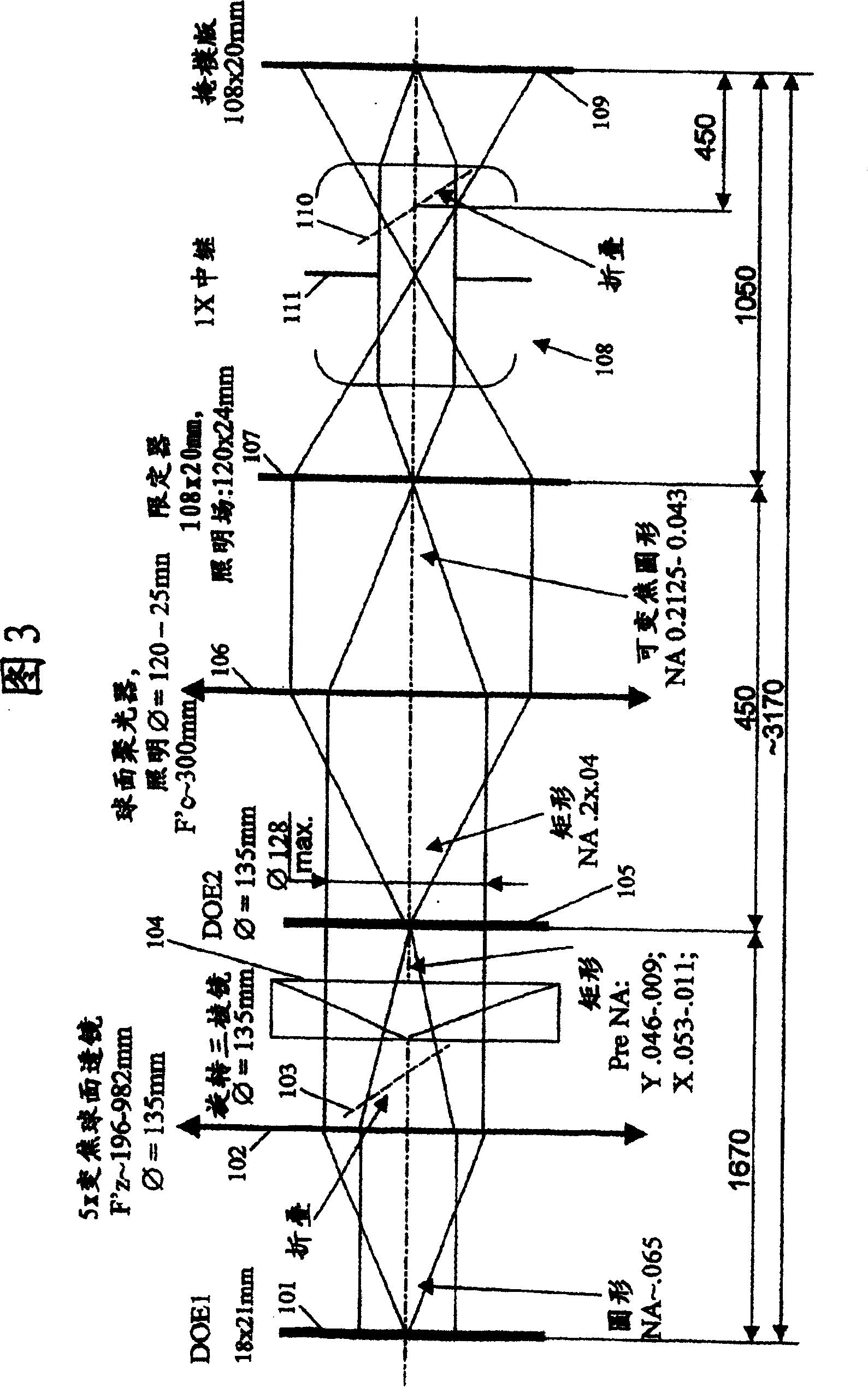

[0028] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

[0029] In recent years, the photolithography methods used to fabricate semiconductor devices have gradually moved to shorter wavelengths as device features shrink in size. With feature sizes shrinking to the sub-micron, and sub-0.1 micron range, semiconductor manufacturers have had to change to using ultraviolet light, and in some cases soft X-ray lithography (or deep UV). For example, excimer lasers, which emit light in the 248, 193, and 157 nm range, are increasingly used in semiconductor device fabrication. The illumination source in a modern microlithographic apparatus, as noted above, is usually a visible laser, an excimer laser, or possibly a soft X-ray source. (The terms "light" and "illumination" will be used interchangeably herein to refer to any electromagnetic radiation applied to the photoresist). The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com