High efficiency aliphatic sulfonate water reducing agent and method for preparing same

A technology of aliphatic sulfonate and high-efficiency water reducer, which is applied in the field of aliphatic sulfonate high-efficiency water reducer and its preparation, and can solve the problems of poor adaptability of cement varieties, large fluctuations in industrial naphthalene prices, and complicated manufacturing processes, etc. problem, to achieve the effect of good use environment, avoid gelling phenomenon, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

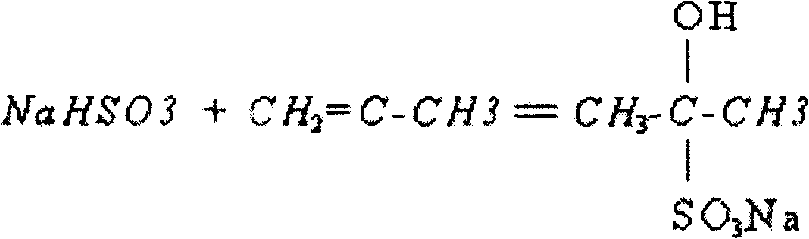

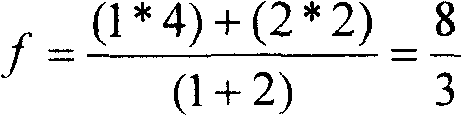

Method used

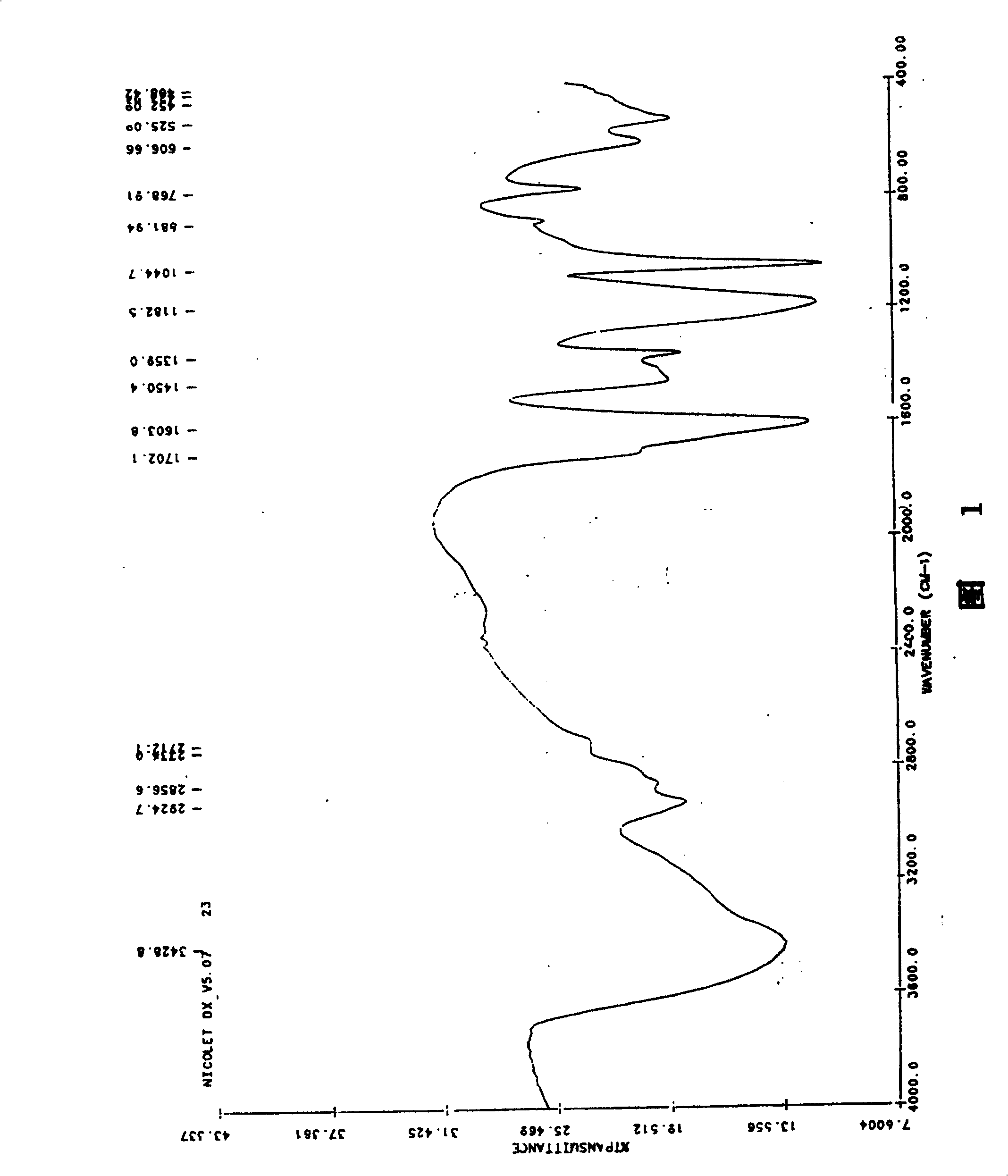

Image

Examples

Embodiment 1

[0024] The synthetic reactions respectively described in this embodiment and the following embodiments are carried out in a reaction vessel equipped with an electric stirrer, a thermometer, a dropping funnel and a reflux condenser.

[0025] First, put 12.5 moles of water into the reaction vessel, preheat it to 30°C, then add 0.52 moles of anhydrous sodium sulfite to carry out the hydrolysis reaction of the sulfonating agent; then, add 0.96 moles of acetone, and reflux for 30 to 60 minutes; then Add 2.2 moles of formaldehyde with a concentration of 37% to the above solution from the dropping funnel to carry out the carbonylation reaction. The temperature for starting to add formaldehyde is 40-60°C. At the beginning, formaldehyde should be added dropwise slowly, and then gradually increase the speed of adding formaldehyde. After the formaldehyde is added, the temperature of the reaction system is automatically raised to the range of 85-96°C; then heated to 90-110°C, reacted at th...

Embodiment 2

[0027] First, put 8.3 moles of water into the reaction vessel, preheat to 30°C, then add 0.62 moles of anhydrous sodium sulfite to carry out the hydrolysis reaction of the sulfonating agent; then, add 0.51 moles of cyclohexanone, and reflux for 30 to 60 minutes ; Then drop 0.87 moles of formaldehyde with a concentration of 37% into the above solution from the dropping funnel to carry out the carbonylation reaction. Adding speed; after the formaldehyde is added, the temperature of the reaction system is automatically raised to the range of 85-96°C; then heated to 90-110°C, reacting at this temperature for 2-6 hours, and performing a high-temperature condensation reaction to obtain The amber transparent liquid with a concentration of about 40% is the aliphatic sulfonate superplasticizer.

Embodiment 3

[0029] First, put 11 moles of water into the reaction vessel, preheat it to 30°C, then add 0.67 moles of anhydrous sodium sulfite to carry out the hydrolysis reaction of the sulfonating agent; then, add 0.96 moles of acetone, and reflux for 30 to 60 minutes; then Add 2.23 moles of formaldehyde with a concentration of 37% dropwise from the dropping funnel to the above solution to carry out the carbonylation reaction. The temperature for starting to add formaldehyde is 40-60°C. The formaldehyde should be added dropwise at the beginning, and then gradually increase the speed of adding formaldehyde. After the formaldehyde is added, the temperature of the reaction system is automatically raised to the range of 85-96°C; then heated to 90-110°C, reacted at this temperature for 2-6 hours, and carried out high-temperature condensation reaction to obtain a concentration of 30-40% of the liquid is the aliphatic sulfonate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com