A kind of quick-drying quick-setting cement superplasticizer composition

A technology of water reducing agent and composition, applied in the field of cement water reducing agent composition, can solve the problems of limited improvement of fluidity cement strength, poor fluidity, poor water reduction rate, small influence of cement strength, etc., and achieves the promotion of hydrophilic performance. , High water reduction rate, improve the effect of water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

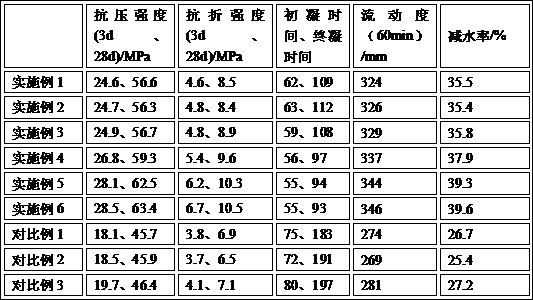

Examples

Embodiment 1

[0029] Example 1, a fast-drying fast-condensing cement superplasticizer composition, wherein: the raw material is composed of the following components: malic acid, sodium chloride, phenolic resin, polypropylene oxide, acrylic acid, hydrogen peroxide, deionized water, sodium hydroxide; wherein the concentration of hydrogen peroxide is 8mol / L.

[0030] Among them, according to the weight, 3 parts of malic acid, 4 parts of sodium chloride, 15 parts of phenolic resin, 20 parts of polyethylene oxide, 12 parts of acrylic acid, 40 parts of deionized water, and 3 parts of 8mol / L hydrogen peroxide.

[0031] Malic acid, sodium chloride, phenolic resin, polyeprylic propylene oxide, acrylic acid, deionized water added to the container for stirring and mixing, and the water bath is heated to 50 ° C, and then slowly add 8mol / L of hydrogen peroxide, hydrogen peroxide is added for a total of 20min, hydrogen peroxide after the addition of 60min, and then cooled to room temperature, added a con...

Embodiment 2

[0032] Example 2, a fast-drying fast-condensing cement superplasticizer composition, wherein: the raw material is composed of the following components: malic acid, sodium chloride, phenolic resin, polyolamine, acrylic acid, hydrogen peroxide, deionized water, sodium hydroxide; wherein the concentration of hydrogen peroxide is 5mol / L.

[0033] Among them, according to the weight, 6 parts of malic acid, 8 parts of sodium chloride, 8 parts of phenolic resin, 10 parts of polyethylene propylene oxide, 18 parts of acrylic acid, 60 parts of deionized water, 6 parts of 5mol / L hydrogen peroxide.

[0034] Malic acid, sodium chloride, phenolic resin, polyeprylic propylene oxide, acrylic acid, deionized water added to the container for stirring and mixing, and the water bath is heated to 70 ° C, and then slowly add 5mol / L of hydrogen peroxide, hydrogen peroxide is added for a total of 40min, hydrogen peroxide is added after the reaction continues for 30min; then cooled to room temperature...

Embodiment 3

[0035]Example 3, a fast-drying fast-condensing cement superplasticizer composition, wherein: the raw material is composed of the following components: malic acid, sodium chloride, phenolic resin, polypropylene oxide, acrylic acid, hydrogen peroxide, deionized water, sodium hydroxide; wherein the concentration of hydrogen peroxide is 6mol / L.

[0036] Among them, according to the weight, 5 parts of malic acid, 6 parts of sodium chloride, 10 parts of phenolic resin, 15 parts of polyethylene oxide, 16 parts of acrylic acid, 50 parts of deionized water, and 4 parts of 6mol / L hydrogen peroxide.

[0037] Malic acid, sodium chloride, phenolic resin, polyeprylic propylene oxide, acrylic acid, deionized water added to the container for stirring and mixing, and the water bath heated to 60 ° C, and then slowly add 6mol / L of hydrogen peroxide, hydrogen peroxide total addition time of 25min, hydrogen peroxide after addition to continue to react for 40min; then cooled to room temperature, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com