Supersonic wave intensified bioenzyme grease degumming method

A grease degumming and ultrasonic technology, applied in the direction of fat production, fat oil/fat refining, etc., to achieve the effect of low operating cost, high efficiency, and reduced clay consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

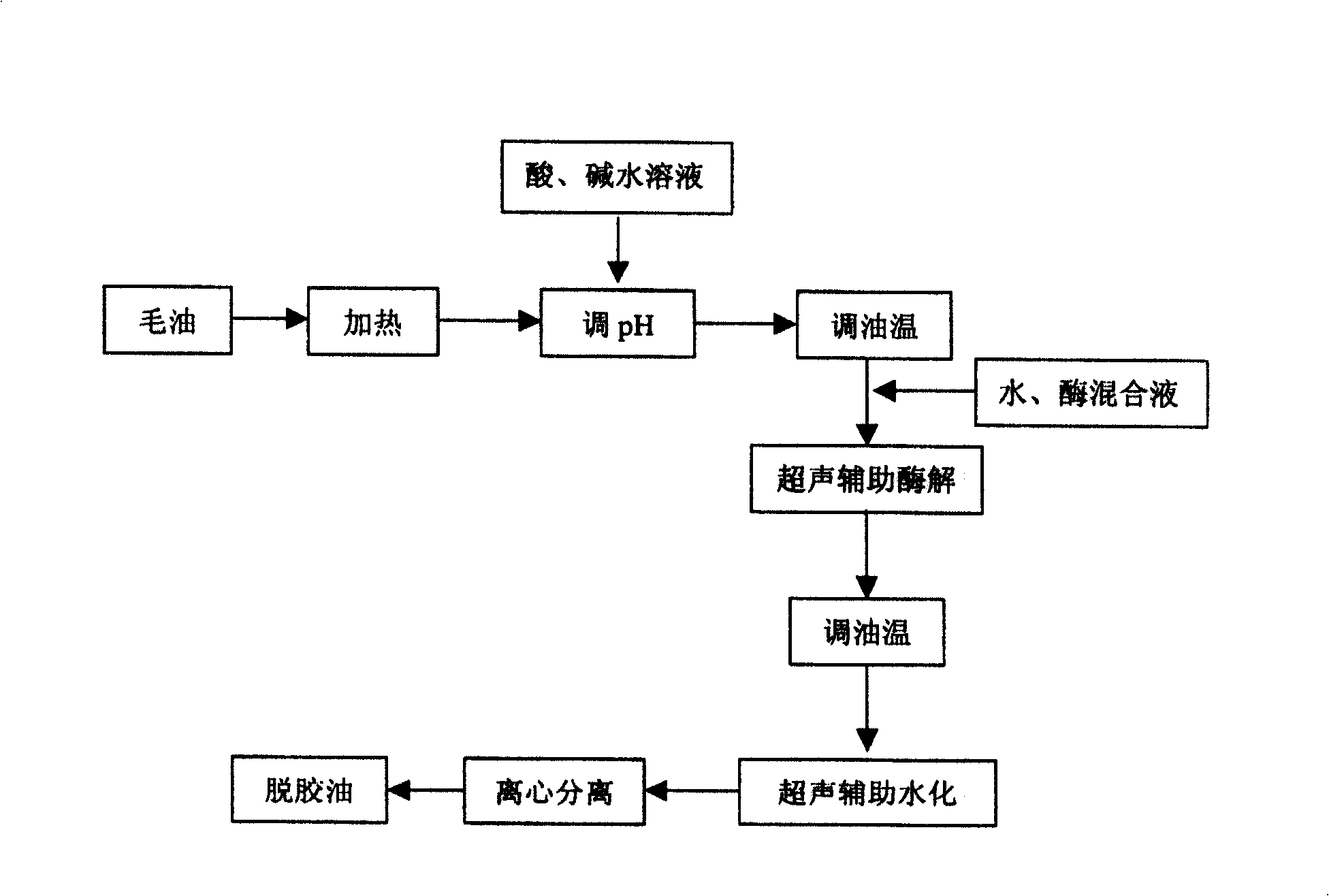

Method used

Image

Examples

Embodiment 1

[0018] As shown in the attached drawings, pump the hydrated and degummed canola oil, heat it through a heat exchanger, and the oil temperature rises to 40-85°C, then open the citric acid storage tank and the NaOH storage tank in turn, 35%-55 % citric acid aqueous solution, 2%~9% NaOH aqueous solution and oil (the addition ratio of citric acid and sodium hydroxide is 2: 3~4, the addition amount of citric acid is 0.03%~0.05% of the oil weight in the blending tank, with After being fully mixed in a strong mixer, it is pumped into the mixing tank, and the temperature of the oil-water mixture is controlled between 50 and 90°C, and the oil-water emulsion is blended at a stirring speed of 100-200 r / min for 10-30 minutes. The pH of the mixture is between 4 and 6. The reconciled oil-water emulsion passes through the heat exchanger, and the oil temperature is adjusted to between 20 and 70 ° C. After mixing with the aqueous solution of phospholipase Al (the addition amount is 50 to 200 U...

example 2

[0020] As shown in the attached drawings, the hydrated and degummed soybean oil is pumped in, heated by a heat exchanger, the oil temperature rises to 35-80°C, and then the citric acid storage tank and the NaOH storage tank are opened in turn, 35% to 55% lemon Acid aqueous solution, 2%~9% NaOH aqueous solution and oil (the addition ratio of citric acid and sodium hydroxide is 2:3~4.5, and the addition amount of citric acid is 0.05%~0.07% of the oil weight in the mixing tank, by weight) After being fully mixed in a strong mixer, it is pumped into the blending tank, and the temperature of the oil-water mixture is controlled at 45-90 °C, and the oil-water emulsion is blended at a stirring speed of 80-380 r / min for 15-50 minutes. At this time, the pH value of the oil-water mixture between 5 and 7. The reconciled oil-water emulsion passes through the heat exchanger. At this time, the oil temperature is adjusted to between 25 and 75°C. After mixing with the aqueous solution of phosp...

example 3

[0022]As shown in the attached figure, the hydrated and degummed cottonseed oil is pumped in, heated by a heat exchanger, and the oil temperature rises to 40-80°C, and then the citric acid storage tank and the NaOH storage tank are opened sequentially, and 35%-55% lemon Aqueous acid solution, 2% to 9% NaOH aqueous solution and oil (the ratio of citric acid and sodium hydroxide is 2:3 to 4, and the amount of citric acid added is 0.04% to 0.06% of the weight of the oil in the blending tank, by weight) After fully mixed in the intensive mixer, it is pumped into the blending tank, the temperature of the oil-water mixture is controlled at 50-80°C, and the oil-water emulsion is blended at a stirring speed of 120-320r / min for 20-60min. At this time, the pH value of the oil-water mixture Between 4.5 and 6.5. The reconciled oil-water emulsion passes through a heat exchanger, and the oil temperature is adjusted to 30-60°C. After being mixed with the aqueous solution of phospholipase (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com