Detergent compositions and processes for the production thereof

一种组合物、洗涤剂的技术,应用在洗涤剂组合物、表面活性洗涤剂组合物、有机洗涤组合物等方向,能够解决氨基酸过量、繁杂等问题,达到泡沫保持性优异、起泡性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

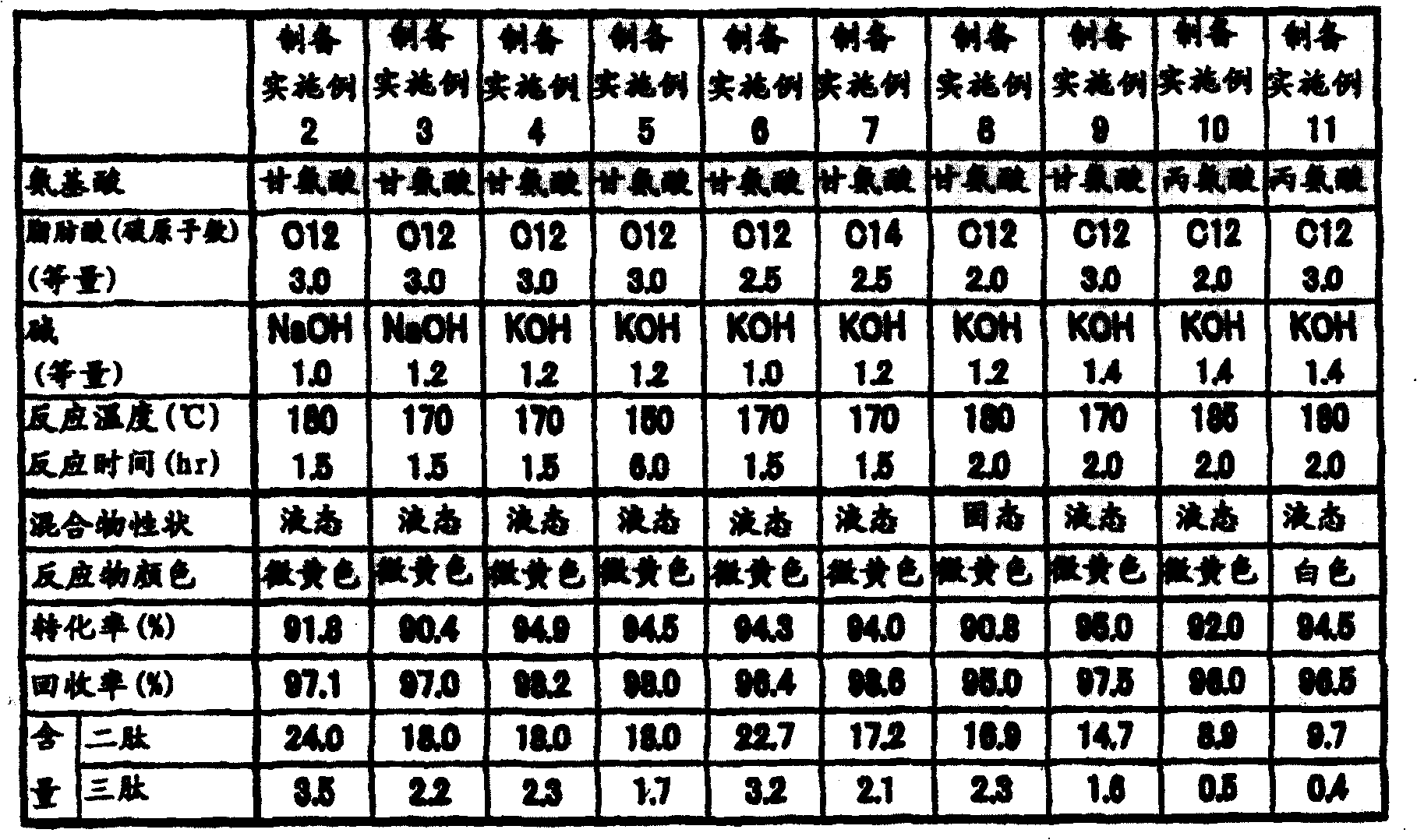

preparation example Construction

[0042] The preparation method of the present invention is to mix and heat (a) long-chain fatty acid, (b) neutral amino acid, and (c) one or both of sodium hydroxide and potassium hydroxide, and continuously remove the water generated therebetween, thereby A preparation method for obtaining N-long-chain acyl neutral amino acid salts, such as N-long-chain acyl glycine salts. Here, continuously removing the generated water refers to actively removing the water generated by neutralization with an alkaline substance and the water generated by the condensation reaction. Specifically, it can be removed together with an inert gas flow, or removed under reduced pressure, etc. to implement.

[0043] The long-chain fatty acid used as a raw material for the preparation method of the present invention is a saturated or unsaturated linear or branched fatty acid having 8 to 22 carbon atoms. The fatty acid may consist of one type of fatty acid, or may be in the form of a so-called mixed fatt...

Embodiment 1~6 and comparative example 1~3

[0055] Examples 1 to 6 and Comparative Examples 1 to 3

[0056] The detergent components were mixed in the ratio shown in Table 1 below, and an aqueous solution having a total content of the detergent components of 10% by weight was prepared. Each aqueous solution was diluted 40 times (cleaning component concentration 0.25%), stirred with a mixer at a temperature of 30° C., and the amount of foam after stirring for 1 minute and 5 minutes was measured. In addition, the foam retention rate represents the value of the amount of foam after 5 minutes of stirring with a mixer with respect to the amount of foam after 1 minute in percentage. In Example 1, fatty acids were removed from the reaction mixture obtained in Preparation Example 9 described later to obtain a mixture of acyl amino acids and acyl peptides, which were then used as their respective sodium salts.

[0057]The evaluation of the amount of foam and foam retention in Table 1 was evaluated by the amount of foam (value ...

Embodiment 7~12

[0073] Examples 7 to 12 and Comparative Examples 4 to 5

[0074] The same evaluation was performed for alanines. The results are shown in Table 2 below. The evaluation of the amount of foam in this table is the evaluation of the amount of foam after stirring with a mixer for 1 minute, ◎: 250 ml or more, ○: 235 ml or more to less than 250 ml, △: 220 ml or more to less than 235 ml, ×: less than 220 ml. Foam retention evaluation was evaluated by the value of foam retention rate, ⊚: 80% or more, ○: 75% or more to less than 80%, △: 65% or more to less than 75%, ×: less than 65%. The sensory evaluation method was the same as the above-mentioned evaluation method for glycines.

[0075] Table 2

[0076] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com