Sulphur meter with automatic cleaning device

A technology of automatic cleaning and sulfur determination instrument, which is applied in the field of sulfur determination instrument, can solve the problems of test data impact, waste of human resources, electrolyte corrosion, etc., to improve accuracy and instrument stability, prevent damage to testing equipment, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

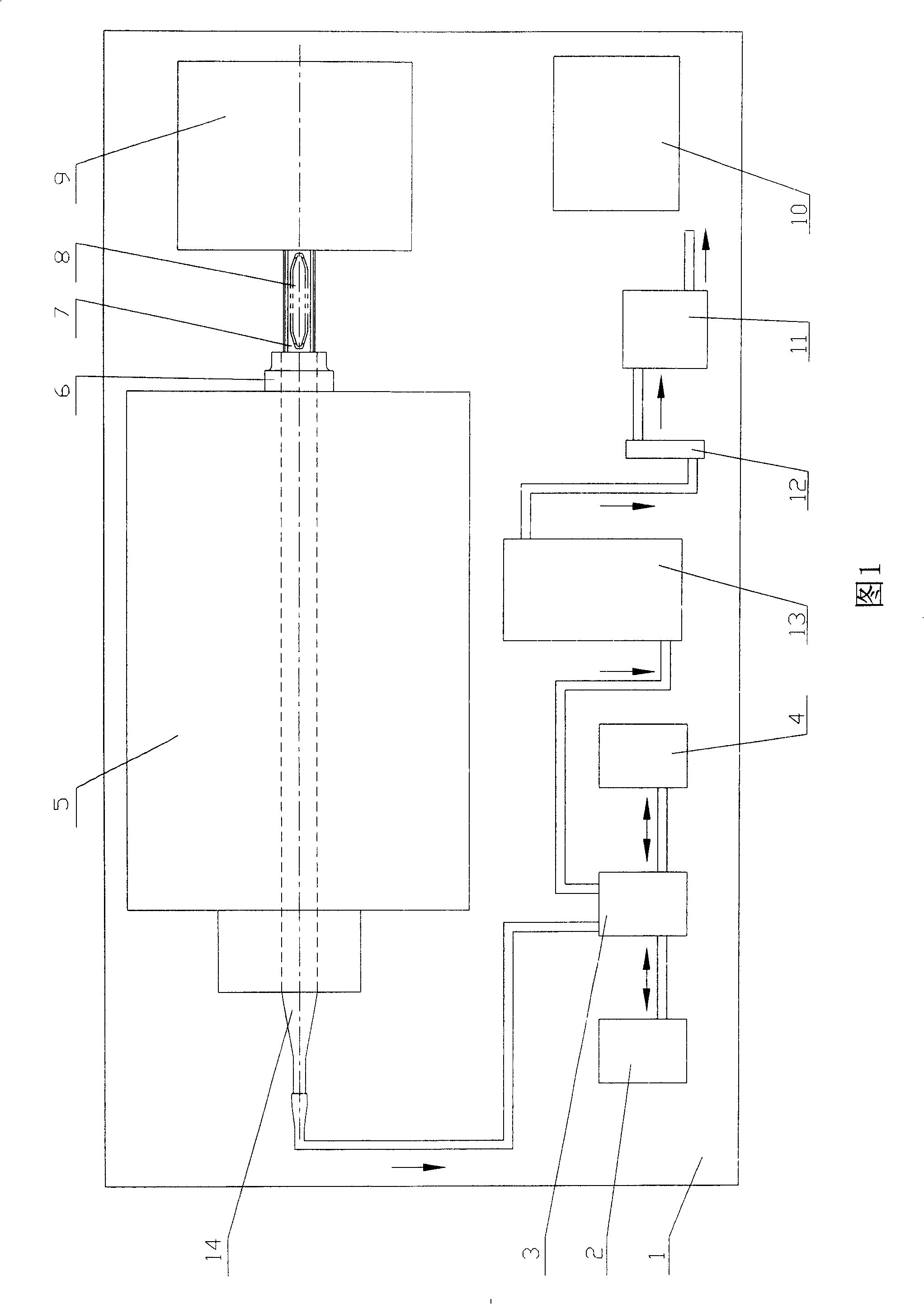

Method used

Image

Examples

Embodiment 1

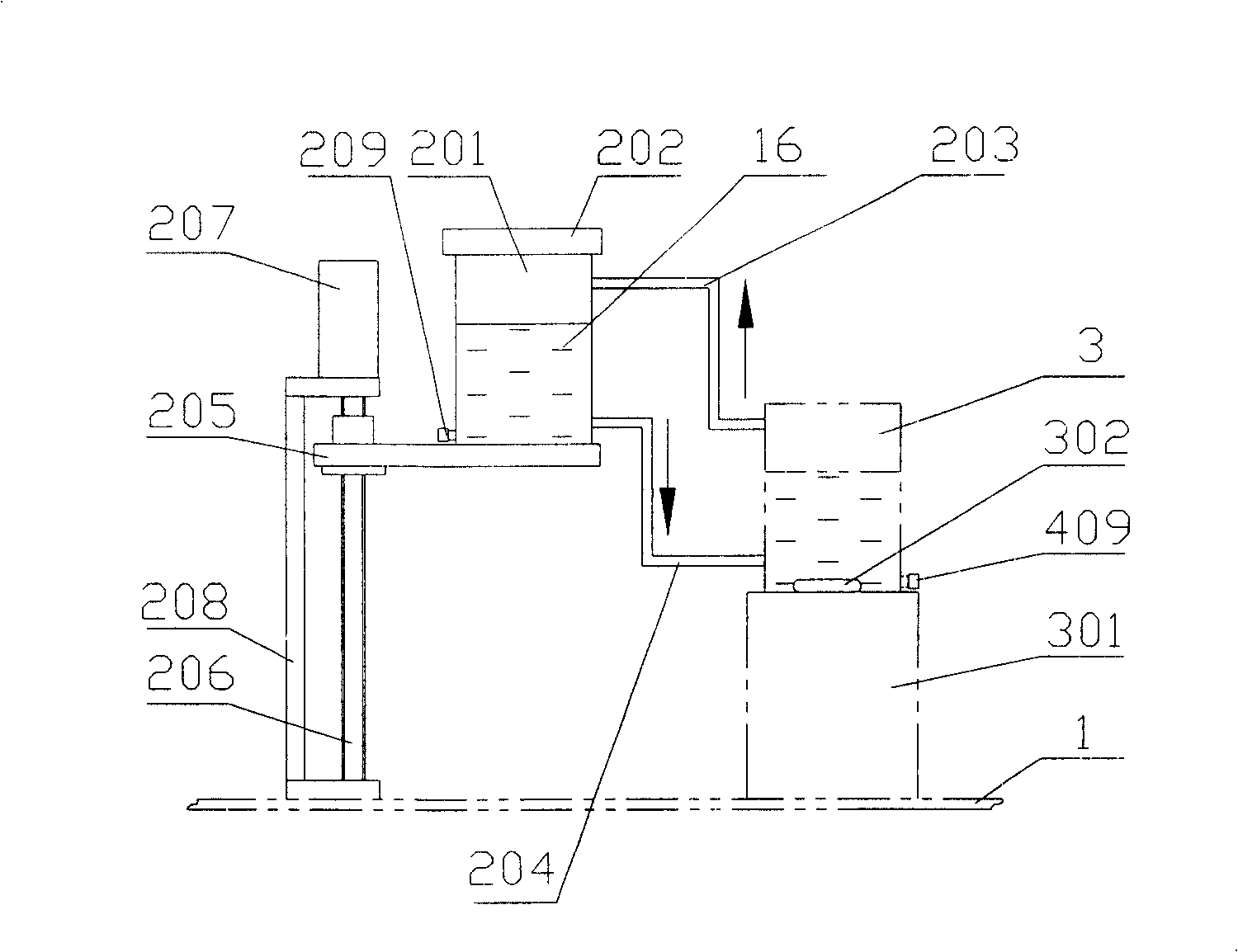

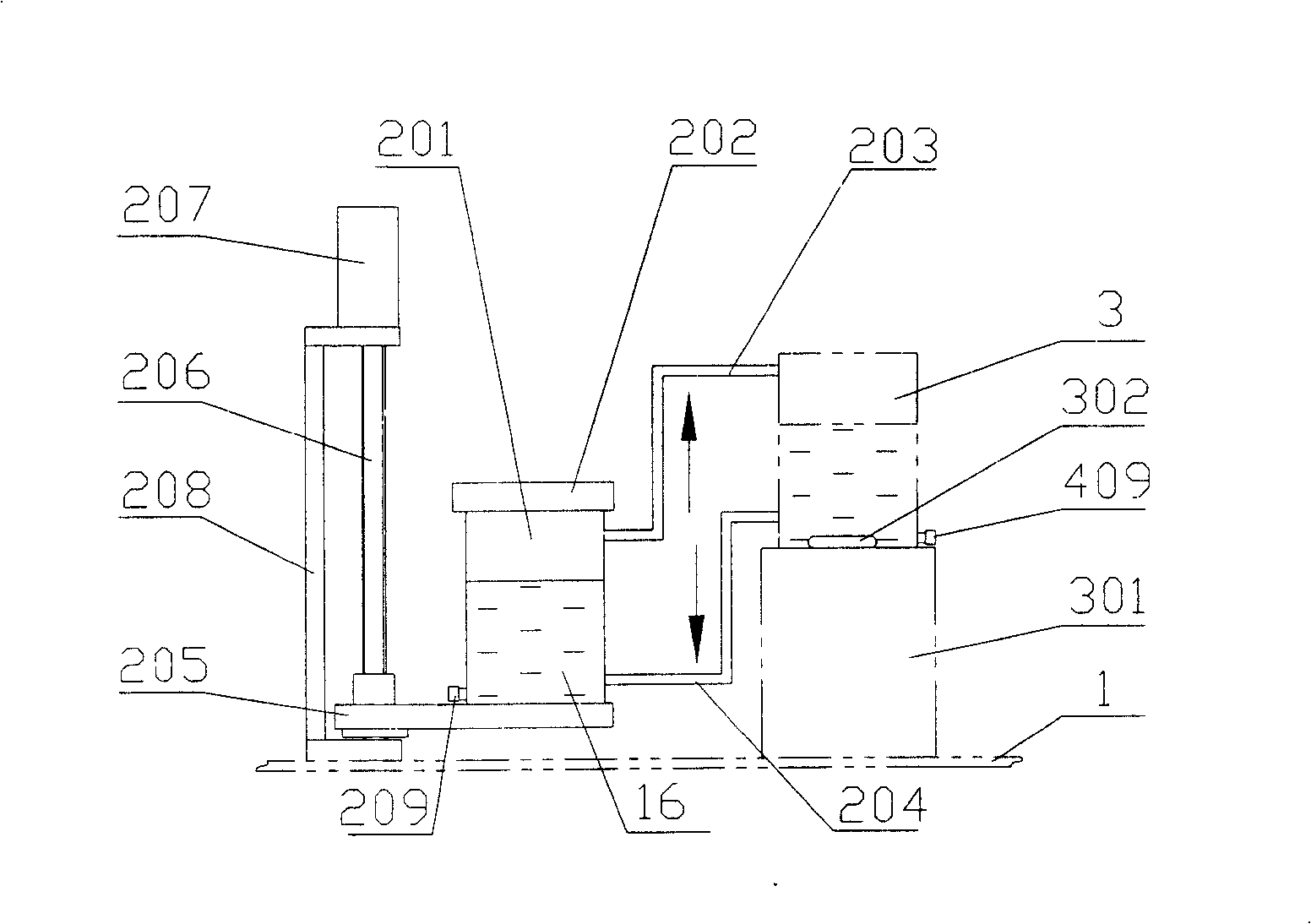

[0061] Embodiment 1: as figure 2 and image 3 As shown, in the present embodiment, the automatic cleaning device 2 includes a cleaning container 201 and a cleaning lifting mechanism, the cleaning container 201 is fixed on the cleaning lifting mechanism, the electrolytic cell 3 communicates with the outside air, and the top of the cleaning container 201 is provided with a cleaning sealing cover 202 , the top and the bottom of the cleaning container 201 are connected to the top and the bottom of the electrolytic cell 3 through the cleaning air guide tube 203 and the cleaning liquid guide tube 204 respectively, and the two ends of the cleaning air guide tube 203 are located between the cleaning container 201 and the liquid in the electrolytic cell 3 Above the highest liquid level, the two ends of the cleaning catheter 204 are located below the liquid level of the liquid in the cleaning container 201 and the electrolytic cell 3 . Driven by the cleaning lifting mechanism, the clea...

Embodiment 2

[0062] Embodiment 2: as Figure 4 and Figure 5 As shown, in the present embodiment, the automatic cleaning device 2 includes a cleaning container 201, a cleaning piston body 210 matched with the cleaning container 201, and a cleaning piston driving device. The cleaning container 201 communicates with the electrolytic cell 3 through a connecting pipe, and the electrolytic cell 3 and The outside air is connected; one end of the cleaning piston body 210 is inserted into the cleaning container 201, and the other end is connected with the cleaning piston driving device. The cleaning piston driving device is a cleaning piston lifting mechanism, and the cleaning piston lifting mechanism includes a cleaning piston lifting platform 211, a cleaning piston lifting screw rod 212, a cleaning piston lifting motor 213 and a cleaning piston lifting frame 214, and the cleaning piston body 210 is fixed on the cleaning piston. On the lifting platform 211, the cleaning piston lifting platform 2...

Embodiment 3

[0063] Embodiment 3: as Image 6 As shown, in the present embodiment, the automatic cleaning device 2 includes a cleaning container 201 and a cleaning pump 215 connected to the cleaning container 201 through a pipeline, the electrolytic cell 3 communicates with the outside air, and the top of the cleaning container 201 is provided with a cleaning sealing cover 202, The cleaning container 201 is not on the same level as the electrolytic cell 3 . In this embodiment, the cleaning container 201 is located higher than the electrolytic cell 3 . The cleaning container 201 is located between the electrolytic cell 3 and the cleaning pump 215. The top and bottom ends of the cleaning container 201 are connected to the electrolytic cell 3 through the first cleaning communication pipe 216 and the second cleaning communication pipe 217 respectively. A fourth directional control valve 218 is provided, and a sixth directional control valve 219 is provided on the communication pipeline connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com