Instant liquid-phase pervasion jointing ternary layered ceramic titanium carbon silicification technique

A diffusion bonding and ternary layered technology, which is applied in the new technology field of instantaneous liquid phase diffusion bonding of ternary layered ceramic titanium silicide, can solve the problems of limiting and reducing the high temperature oxidation resistance of ceramics, and achieves low cost and sample size. Low surface treatment requirements and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

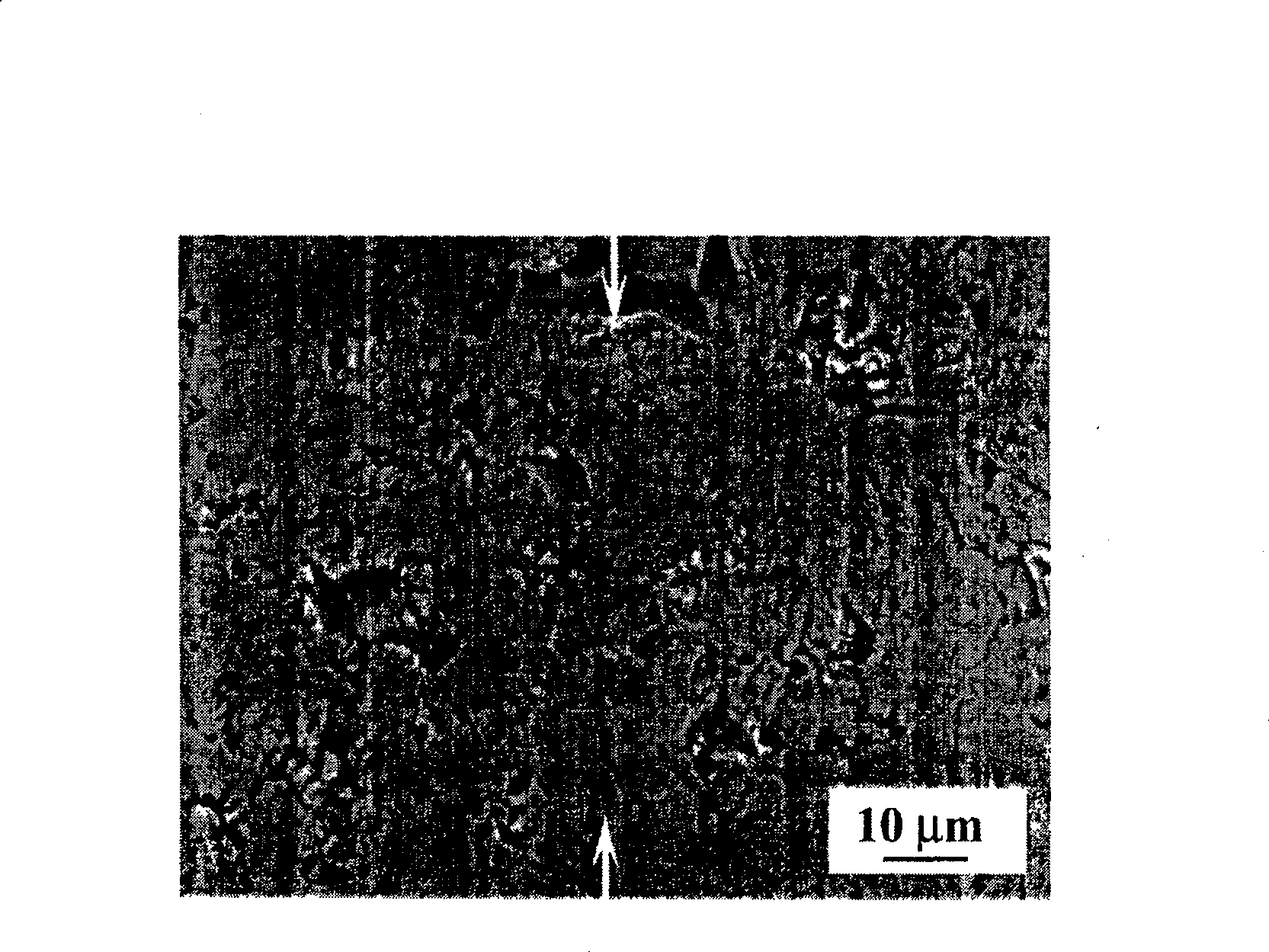

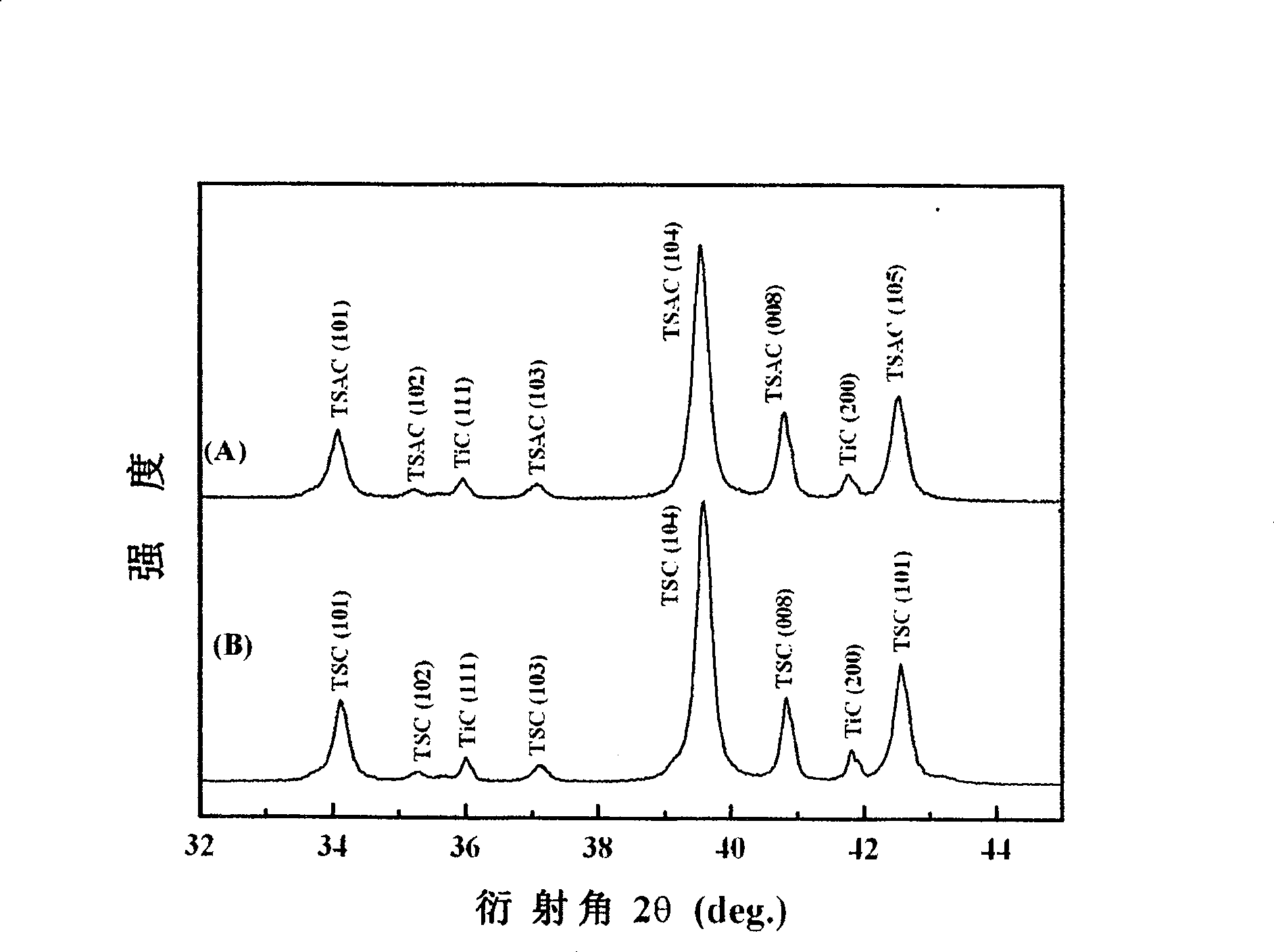

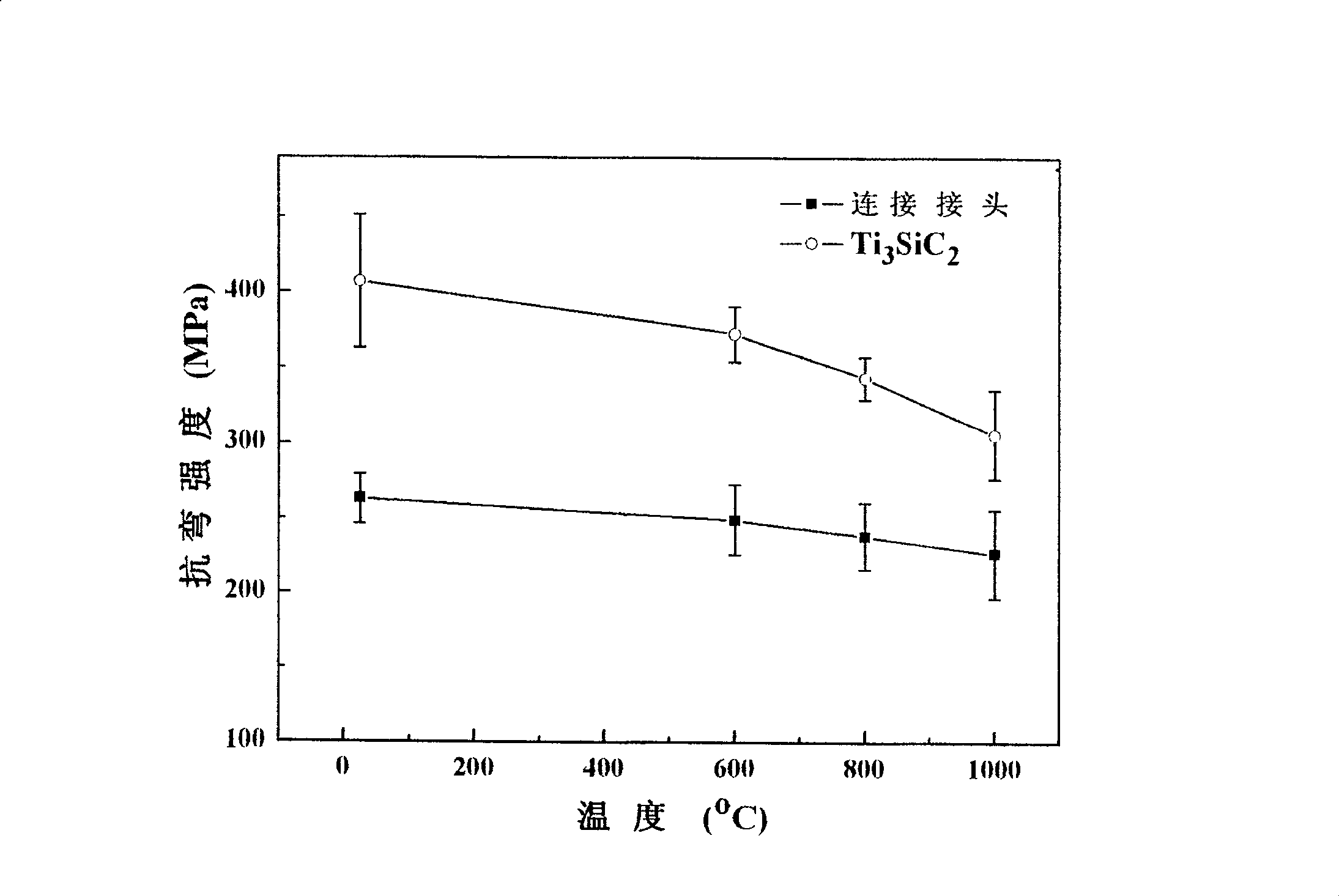

[0017] Ti 3 SiC 2 Ceramic grinding and polishing; aluminum foil with 1000 # Grinding with SiC sandpaper to remove the surface oxide film, the aluminum foil is 50 μm thick after grinding; after the sample is ultrasonically cleaned, the aluminum foil is used as the middle layer, and the upper and lower layers are Ti 3 SiC 2 Ceramics are loaded into a high-temperature hot-press furnace for connection under argon protection. First, keep the temperature at 600°C for 30min at a constant pressure of 20MPa to ensure that Ti 3 SiC 2 Ceramic and Al are in close contact. Then heated at a heating rate of 10°C / min, and simultaneously pressurized to 5 MPa at a loading rate of 0.2kN / min. At 1500°C, keep it warm for 120min, then cool down to 1300°C with the furnace and unload. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and it was found that the elemental Al completely disappeared, the interface was well connected, and ...

Embodiment 2

[0019] Ti 3 SiC 2 Ceramic grinding and polishing; aluminum foil with 1000 # Grinding with SiC sandpaper to remove the surface oxide film, the aluminum foil is 70 μm thick after grinding; after the sample is ultrasonically cleaned, the aluminum foil is used as the middle layer, and the upper and lower layers are Ti 3 SiC 2 Ceramics are loaded into a high-temperature hot-press furnace for connection under argon protection. First, keep the temperature at 600°C for 30min at a constant pressure of 20MPa to ensure that Ti 3 SiC 2 Ceramic and Al are in close contact. Then heat at a rate of 15°C / min, and simultaneously pressurize to 5 MPa at a rate of 0.5kN / min. After heating to 1400°C, keep it warm for 150 minutes, and then cool down to 1200°C with the furnace to unload. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the existence of elemental Al was not observed, and the interface was well connected, and ther...

Embodiment 3

[0021] Ti 3 SiC 2 Ceramic grinding and polishing; aluminum foil with 1000 # Grinding with SiC sandpaper to remove the surface oxide film, the aluminum foil is 100 μm thick after grinding; after the sample is ultrasonically cleaned, the aluminum foil is used as the middle layer, and the upper and lower layers are Ti 3 SiC 2 Ceramics are loaded into a high-temperature hot-press furnace for connection under argon protection. First, keep the temperature at 650°C for 10 minutes at a constant pressure of 10 MPa to ensure that Ti 3 SiC 2 Ceramic and Al are in close contact. Then, it was heated at a rate of temperature increase of 15° C. / min, and simultaneously pressurized to 2 MPa at a rate of 0.2 kN / min. After heating to 1500°C, keep it warm for 180 minutes, and then cool down to 1300°C with the furnace to unload. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the existence of elemental Al was not observed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com