T-shaped beam parallel plate micromechanical variable capacitor and manufacturing process thereof

A technology of variable capacitance and T-shaped beams, which is applied in the direction of variable capacitors, capacitors that change capacitance in a non-mechanical way, capacitors, etc., can solve the incompatibility of mainstream integrated circuit processes, poor repeatability and reliability, and high production costs. problems, to achieve the effects of improved repeatability, reliability, convenience and effective control, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

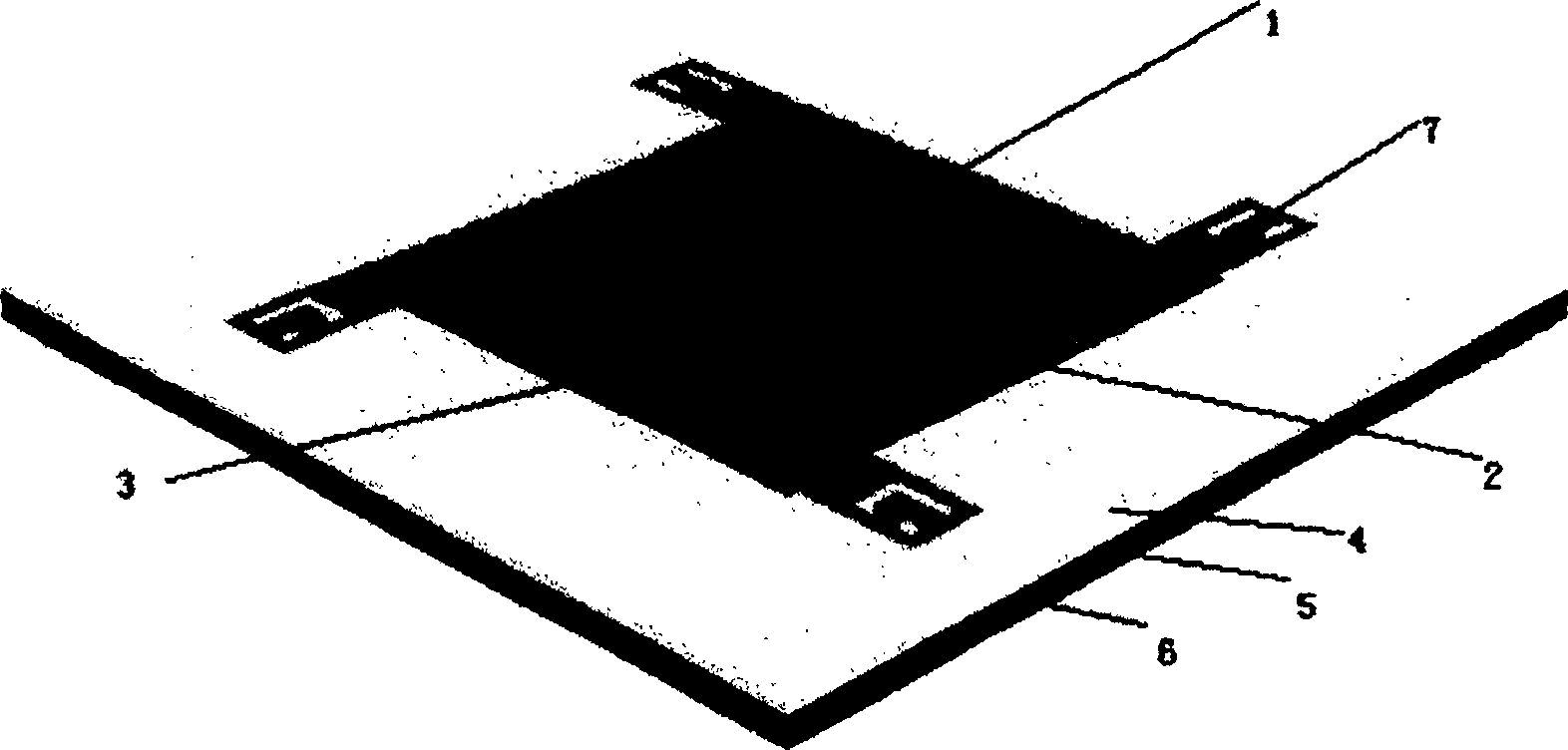

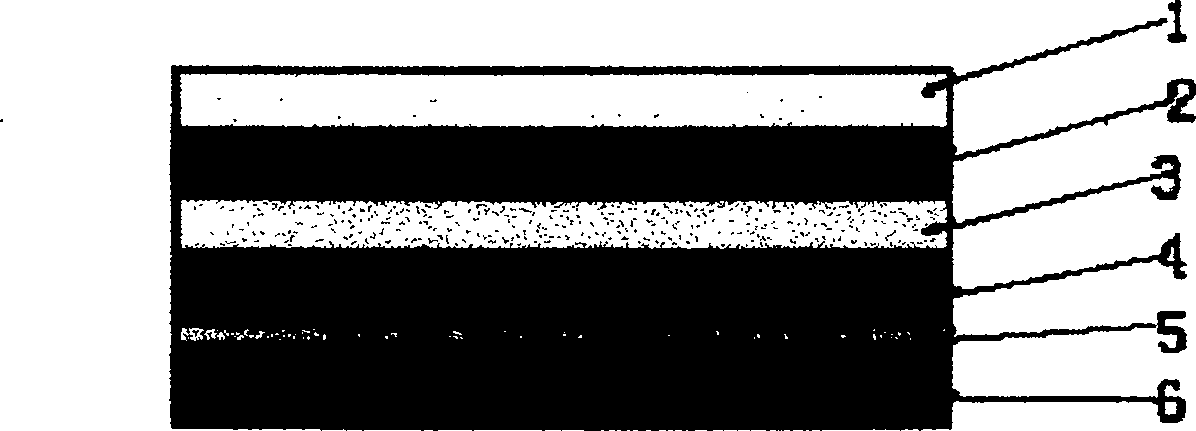

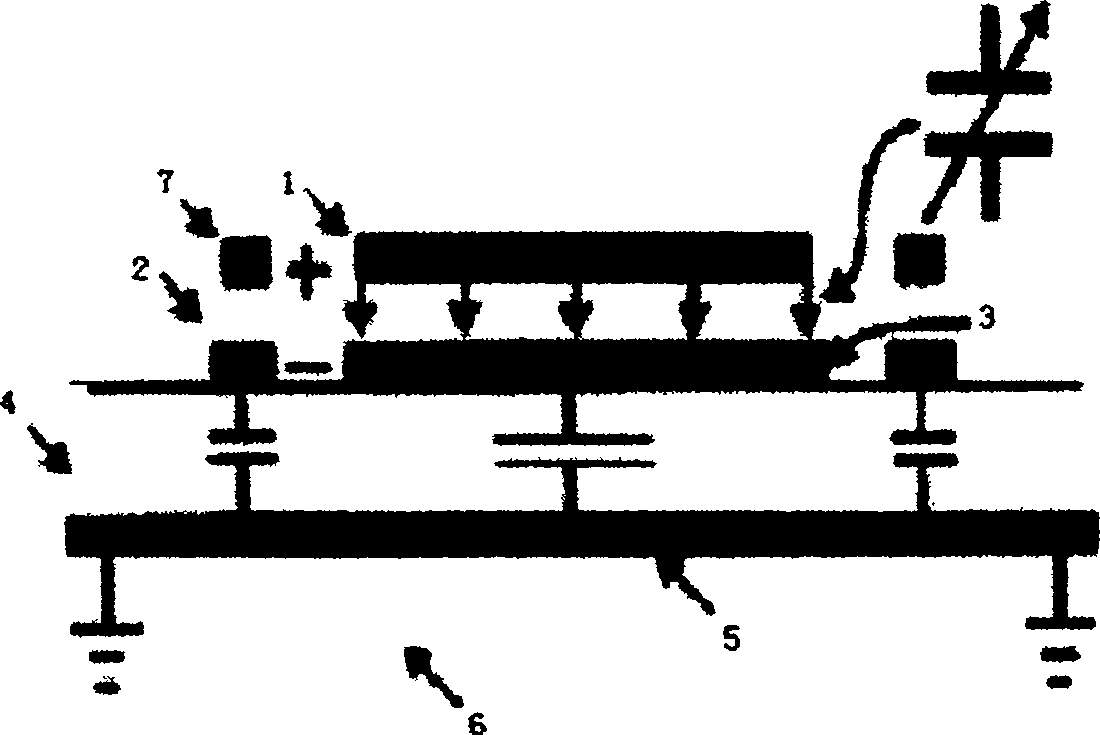

[0031] For the T-beam parallel plate MEMS variable capacitance structure of the present invention, we have proposed a realization method based on CMOS technology. This structure uses the form of voltage change between parallel plates to realize the change of capacitance, and its layered structure is sequential from top to bottom These are: aluminum 1 on the upper plate, dielectric layer 2, aluminum 3 on the lower plate, insulating layer 4, conductive shielding layer 5, and silicon substrate 6; T-beams 7 are arranged symmetrically outside the aluminum 1 on the upper plate. The T-beam 7 is composed of a T-beam connecting arm 7.1 and a T-beam anchoring area 7.2, and a "U"-shaped through-slot 7.3 is opened in the middle of the T-beam connecting arm 7.1, and the T-beam anchoring area 7.2 is located in the " U"-shaped through groove 7.3. An anchor block 7.2.1 is provided at the bottom of the shaped beam anchorage area 7.2.

[0032] We have designed the specific process of T-beam pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com