Indirect heating terminal type microwave power micro-mechanical sensor and preparation method thereof

A technology of micromechanical sensor and microwave power, which is applied in the direction of electric power measurement by thermal method, and the transmission of sensing components and instruments by electric/magnetic devices, which can solve the problems of slow response and low burning level, and achieve fast response speed, Improvement of repeatability reliability and effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

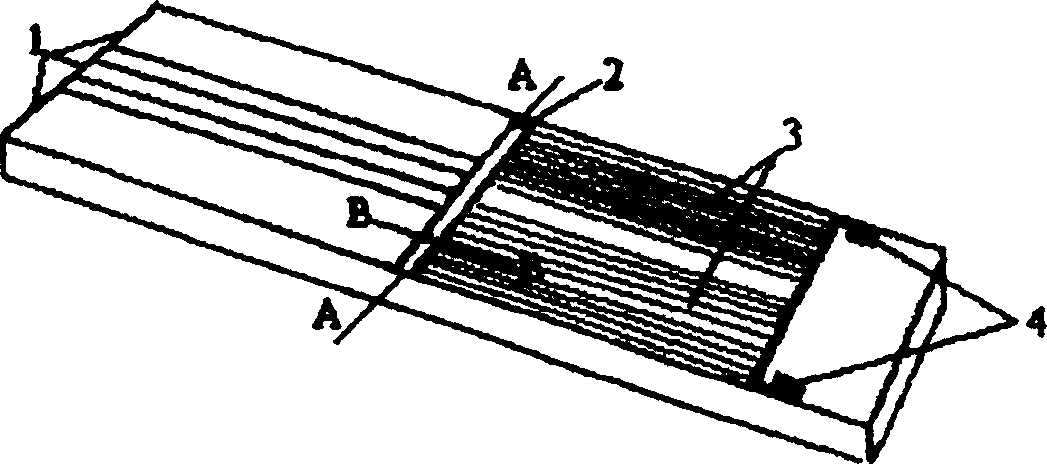

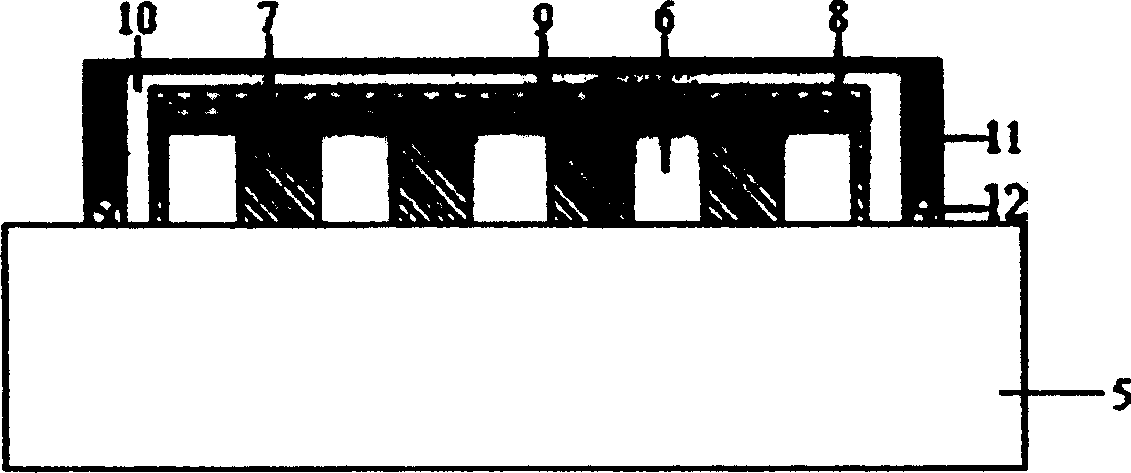

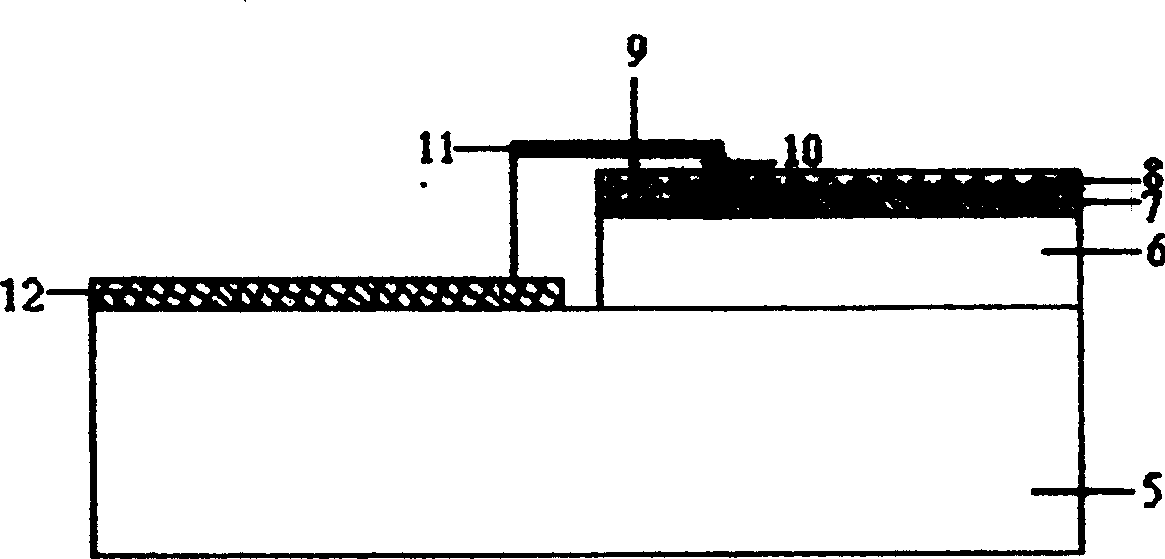

[0032] The specific structure of the indirect heating terminal microwave power micromechanical sensor of the present invention is as follows: a coplanar waveguide 1 and a thermopile 3 are provided on the substrate 5, and a terminal resistor is provided on the inner ends of the coplanar waveguide 1 and the thermopile 3 2. A contact pad 4 is provided at the outer end of the thermopile 3; wherein the thermopile 3 is composed of a thermocouple arm 6, a SiON medium 7, a metal interconnection line 8, and a contact area 9, and the thermocouple arm 6 and the SiON medium 7 are Strips are arranged at intervals along the length direction of the sensor, and a contact area 9 is provided on the thermocouple arm 6, and a metal interconnection line 8 is provided on the SiON medium 7 and the contact area 9; between the coplanar waveguide 1 and the metal interconnection An insulating medium 10 is provided on the inner end of the connection line 8 , and a terminal resistor 2 is provided on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com