Direct heating terminal type micro electronic mechanical system microwave power sensor and its producing method

A technology of microelectronic machinery and microwave power, which is applied in the fields of electric power measurement by thermal method, optical mechanical equipment, metal processing machinery parts, etc. It can solve the problems of inability to integrate digital and analog circuits, low burning level, slow response, etc., and achieve easy High reliability, simple integration, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

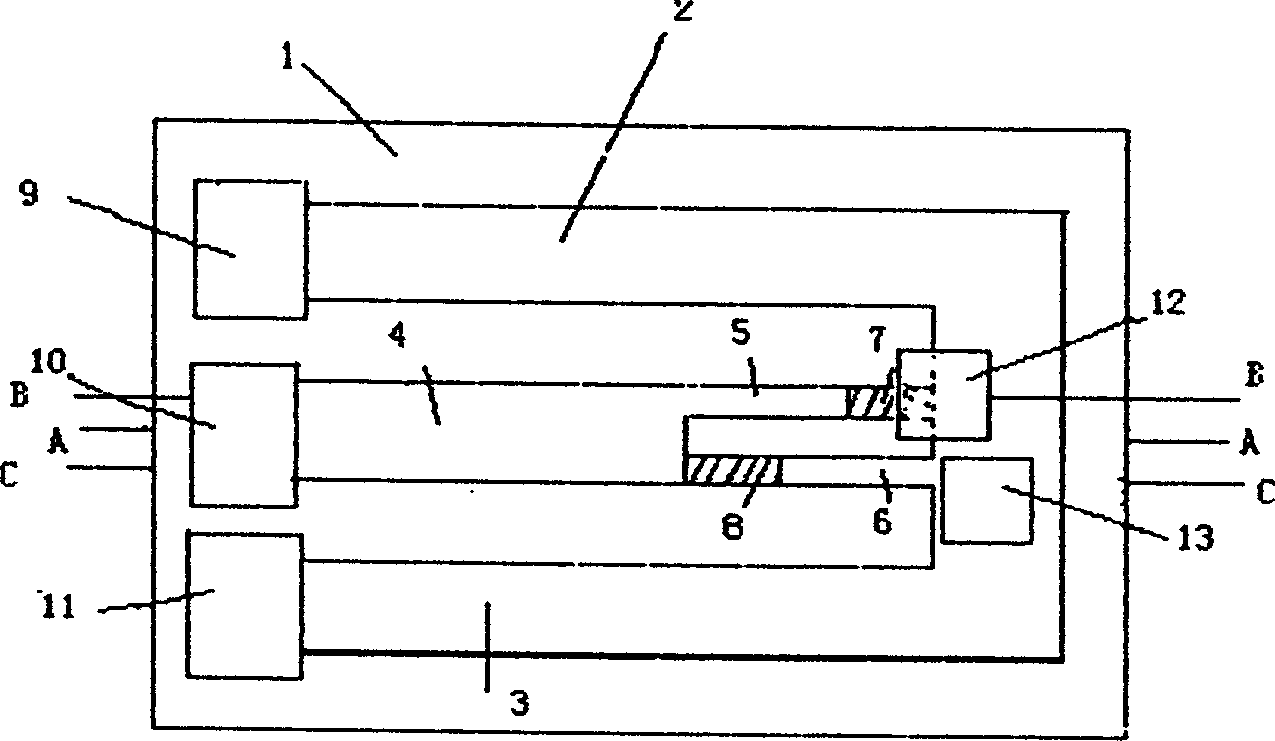

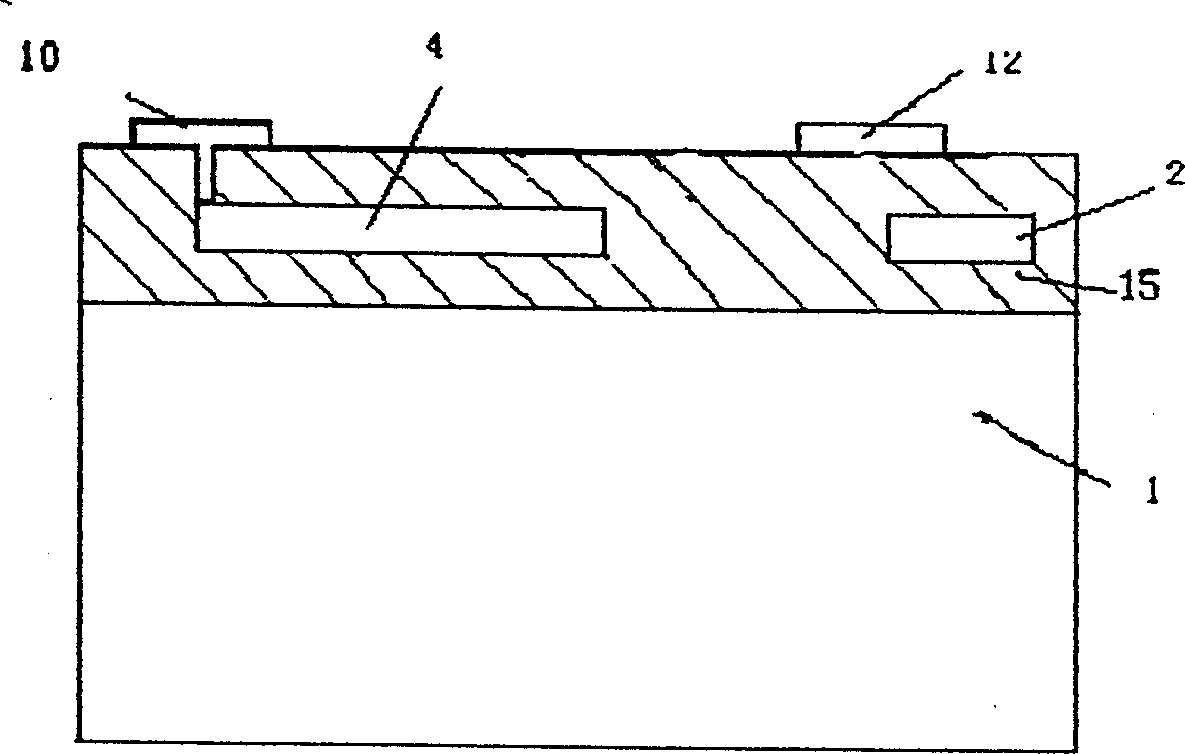

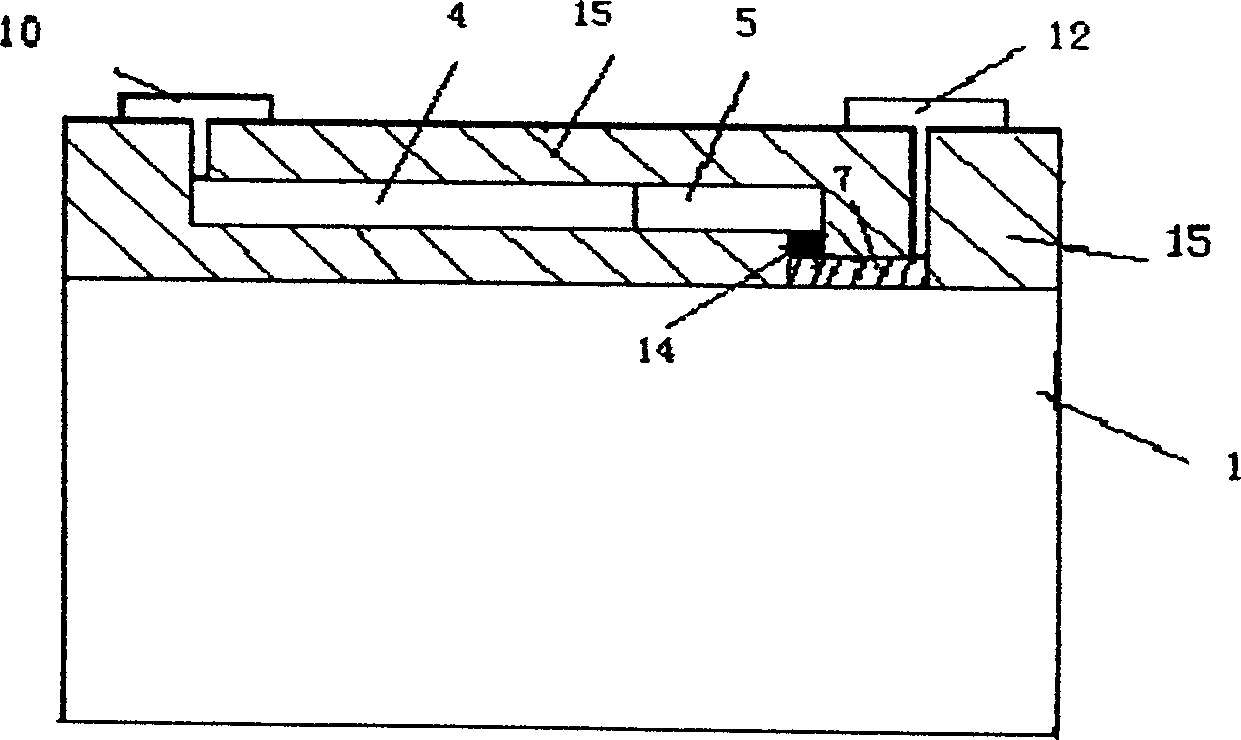

[0032] The structure of the direct heating terminal MEMS microwave power sensor of the present invention has been designed based on a GaAs MMIC process. The direct heating terminal MEMS microwave power sensor structure based on GaAs MMIC technology uses thermocouples as terminal loads, converts the energy input from the coplanar waveguide into heat, and then converts it into voltage to measure the microwave power. In terms of structure The sensor includes a substrate 1, coplanar waveguide ground wires 2, 3, coplanar waveguide signal wires 4, gold thermocouple arms 5, 6, AlGaAs thermocouple arms 7, 8, pads 9, 10, 11, 12, 13 , ohmic contacts 14, 16, 17, and medium 15; wherein, AlGaAs thermocouple arms 7, 8, and medium 15 are directly located on substrate 1, and coplanar waveguide ground wires 2, 3, and coplanar waveguide signal line 4 are located in the middle of medium 15 , the coplanar waveguide ground wires 2, 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com