A preparation method of a room temperature magnetic refrigerating working material Gd5Si2Ge2

A magnetic refrigeration and working fluid technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of inappropriate heat treatment, affecting the efficiency of magnetic refrigeration, magnetic moment and magnetic domain difficulty, etc., and achieve fast response to magnetic field sensitivity. , Improve the magnetic moment density and magnetic domain density, the effect of small external magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The technological process and steps of the embodiment of the present invention are as follows:

[0021] (1) First, the treated high-purity raw materials Gd, Si, Ge are replaced with Gd 5 Si 2 Ge 2 The stoichiometric formula is carried out to obtain the batch material, and the batch material is placed in a vacuum degree of 5.0×10 -2 Melting in an intermediate frequency induction furnace of Pa in an argon-filled atmosphere to obtain an alloy ingot; then crushing it into particles with an average particle size of 1.0mm under a protective atmosphere, and grinding the particles to an average particle size in a high-energy ball mill under a protective liquid 20um powder;

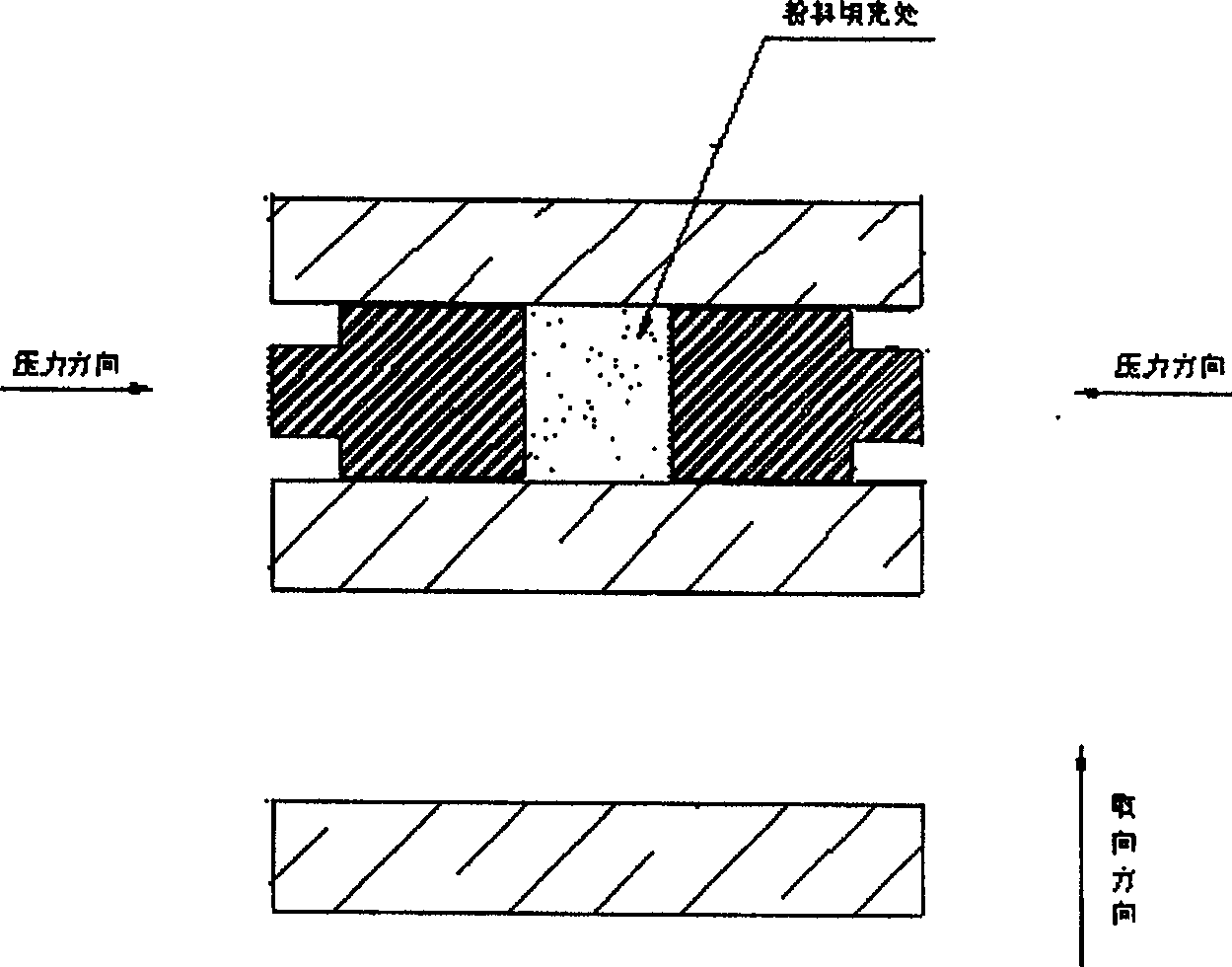

[0022] (2) The above Gd 5 Si 2 Ge 2 The powder is packed in a mold cavity with a material with high magnetic permeability along the direction of the magnetic field (see figure 1 ), magnetization is performed before the powder is pressed, that is, the powder is subjected to magnetic field orientation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com