Preparation method of X-ray diffraction sample rack

A sample holder and X-ray technology, which is applied in the field of preparation of X-ray diffraction sample holders, can solve the problems of interfering with the diffraction information of the tested sample, affecting the reliability of diffraction analysis results, and being prone to cracking, so as to overcome the easy brittle cracking and improve the The effect of toughness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Provide following embodiment in conjunction with content of the present invention:

[0019] (1) Material selection

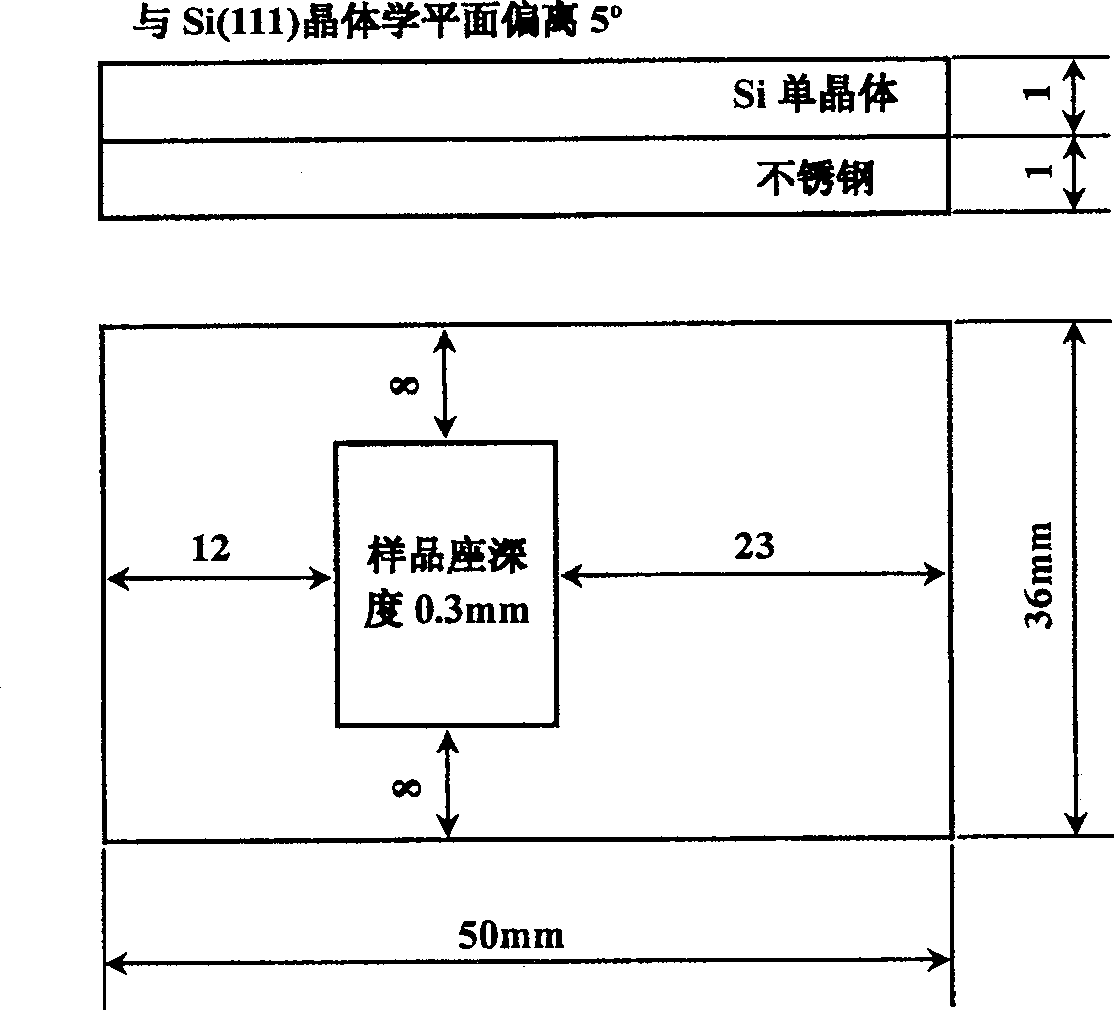

[0020] Si single crystal material is selected for the sample holder, and the (111) crystallographic plane of Si single crystal is determined by using crystal analyzer and Laue diffraction technique, which is its close-packed crystallographic plane and has high fracture strength.

[0021] (2) Cutting the single wafer sample holder blank

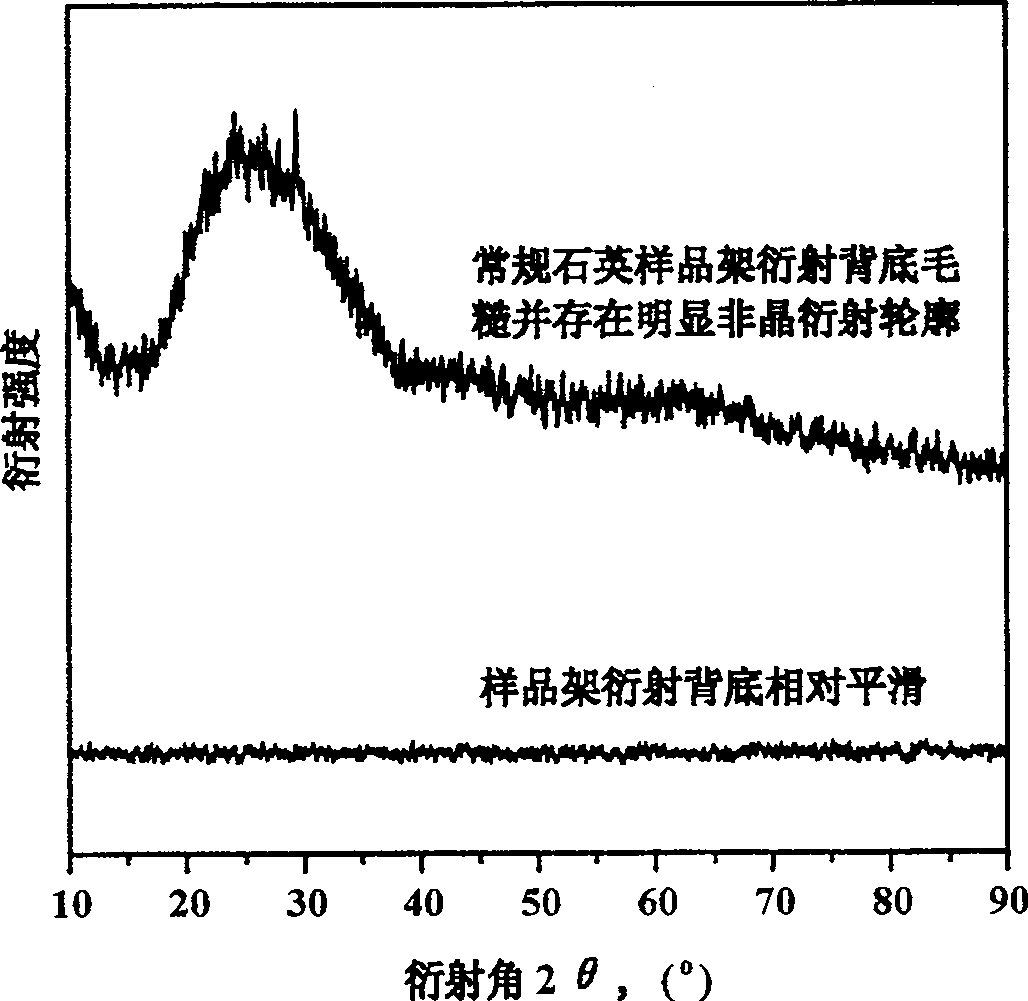

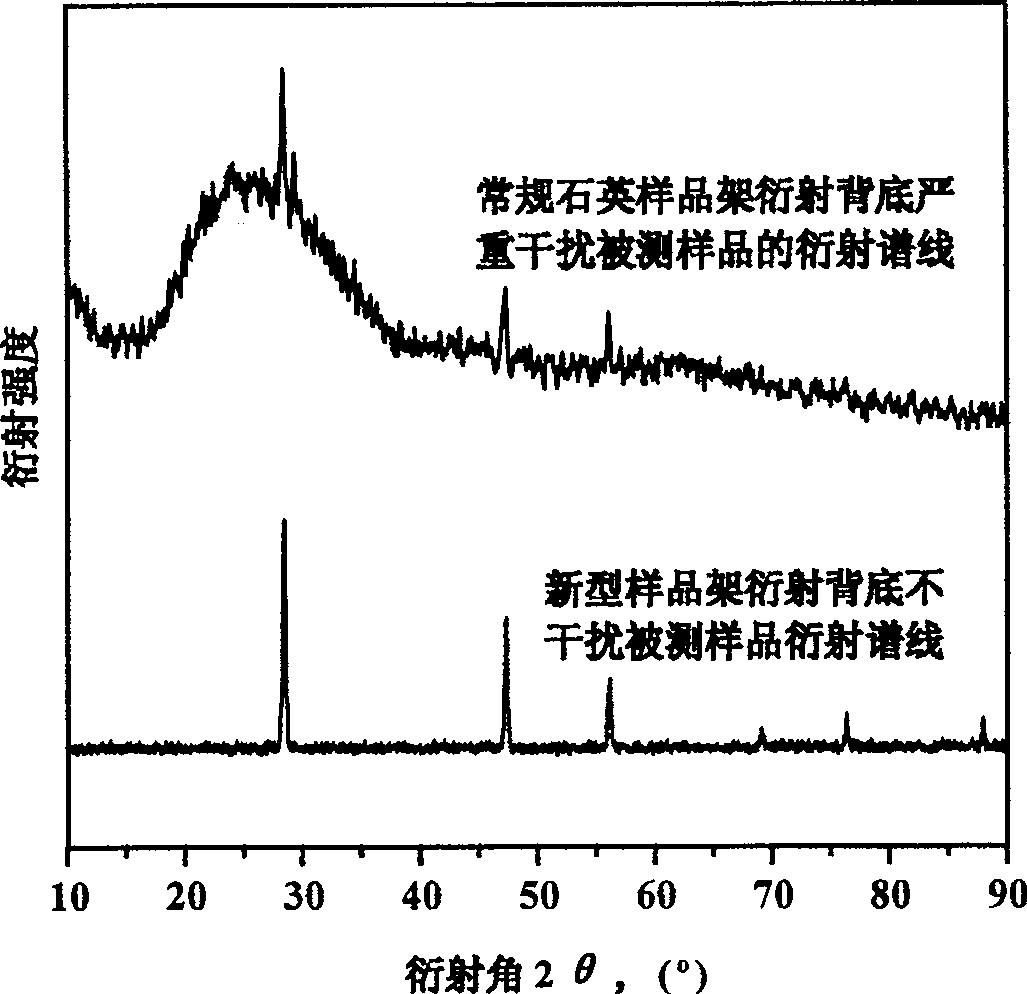

[0022] In order to avoid the Si (111) diffraction peak, choose to deviate from the Si single crystal (111) crystallographic plane by 3-10°, cut out a single wafer with a thickness of 1 mm, and a single crystal sample holder blank with a length of 50 mm and a width of 36 mm. The thickness, length and width are standard size parameters for X-ray diffraction sample holders. The X-ray diffraction results under different deviation angles are shown in the following table. No Si(111) diffraction peak was found in the three cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com