Sintered flux production process

A production process and technology of sintering flux, which is applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of easy sticking to the wall of the dryer cylinder, easy agglomeration of materials themselves, and unstable product quality, etc., to achieve a solution Bonding equipment problems, easy cleaning, and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

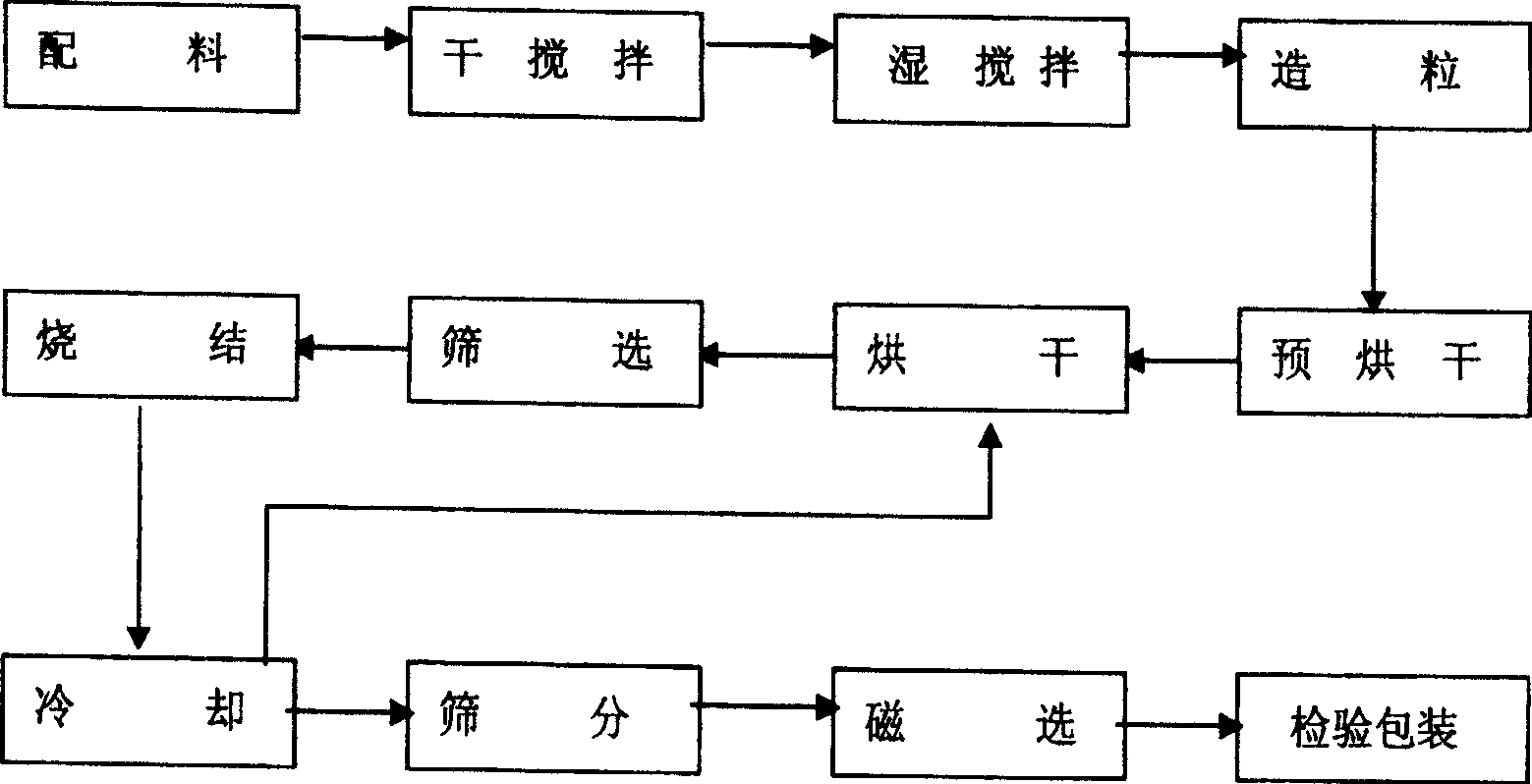

[0026] combined with figure 1 An embodiment of the present invention is described.

[0027] 1. Flux raw material formula (wt%): MgO+CaO=25%~30%; Al 2 o 3 +MnO=20~30%; SiO 2 +TIO 2 =15%~25%; CaF 2 =15%~25%;; FeO=1%~2%, K 2 O+Na 2 O=2%~3%, S≤0.04%, P≤0.04%.

[0028] 2. Flux preparation process:

[0029] ① Ingredients: After re-inspecting the required raw materials, grind them into powders with different standard particle sizes, and mix them according to the required formula after sieving;

[0030] ② Stirring: Put the raw materials with a good ratio into the dry blender for dry blending, and then put them into the wet blender after stirring evenly, and add an appropriate amount of water glass for wet blending; the addition of water glass is carried out by pipeline and automatically measured by electronic scales method.

[0031] ③Granulation: Send the raw materials that have been fully stirred evenly into the granulator for granulation;

[0032] ④ Pre-drying: Use a vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com