Apparatus for processing waste air including oxynitride

A nitrogen oxide and treatment device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as low purification efficiency, economic loss, and difficulty in meeting treatment requirements, and achieve stable absorption performance and absorption saturation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

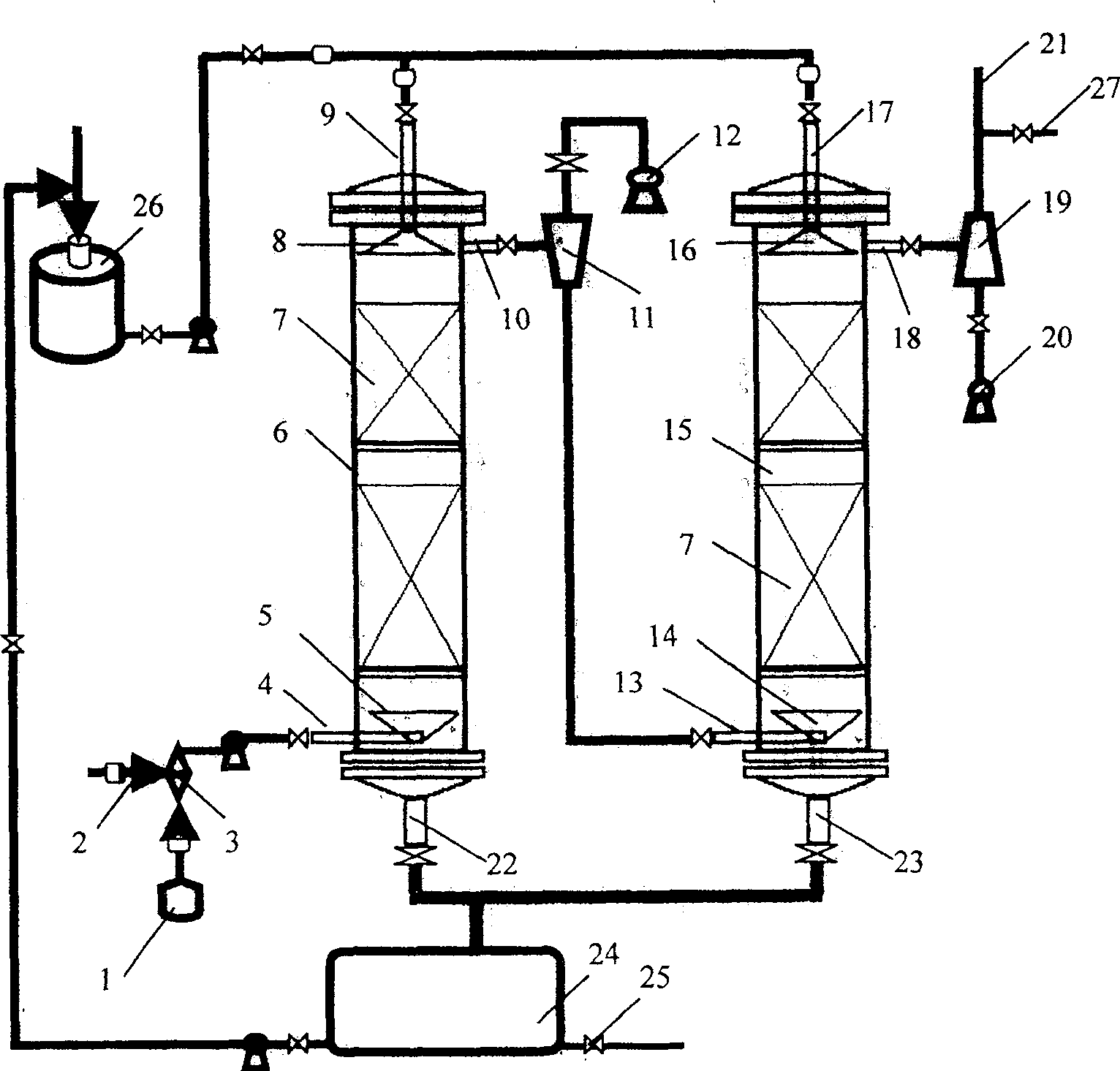

[0029] The structure of the nitrogen oxide-containing waste gas treatment device of the present invention is as follows: figure 1 As shown, it is mainly composed of an ozone generator 1, a nitrogen oxide oxidizer 3, a first packed absorption tower 6, a second packed absorption tower 15, a polyethylene glycol absorption liquid storage tank 26 and an absorption liquid drainage tank 24. The industrial nitrogen oxide waste gas enters the nitrogen oxide oxidizer 3 through the nitrogen oxide flow metering pump and the nitrogen oxide waste gas inlet pipe 2, and the ozone generated by the ozone generator 1 also enters the nitrogen oxide oxidizer 3 through the ozone flow metering pump , to oxidize nitrogen oxides to make NO x All converted to NO 2 gas.

[0030]The absorption liquid in the polyethylene glycol absorption liquid storage tank 26 is regulated by a valve under the power of the feed pump, controlled by the flow controller of the absorption liquid, and passes through the liq...

Embodiment 2

[0036] The nitrogen oxide-containing waste gas treatment device and treatment method of Example 1 of the present invention are used to comprehensively treat the nitrogen oxide-containing waste gas of an enterprise. The company's original exhaust gas volume containing nitrogen oxides is 694m 3 / h, the original emission concentration is 18000mg / m 3 .

[0037] Processing device is designed according to embodiment 1, and some specific design parameters are as follows:

[0038] 1. The packing absorption tower is made of Φ159cm×10mCPVC pipe, and two-stage absorption towers are set;

[0039] 2. Each level of absorption tower is divided into two layers, and the height of the packing layer in the absorption tower is 2.1m;

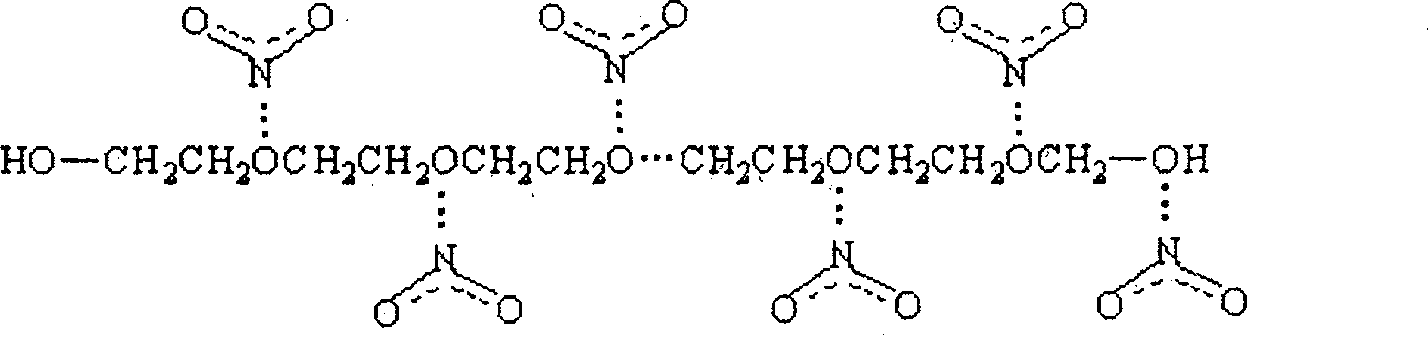

[0040] 3. Polyethylene glycol 300 is used as the absorption liquid, and the absorption liquid is recycled through the circulation pump;

[0041] 4. The gas-liquid mass ratio of the first-stage packing absorption tower is 2:1, and the gas-liquid mass ratio of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com