Method for extracting high pure rebaudioside A from stevia sugar

A stevioside and recrystallization technology, applied in the field of rebaudioside A and natural high-efficiency sweeteners, can solve problems such as bad aftertaste, and achieve the effect of pure taste, high sweetness and pure sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take 5L of mixed solution of methanol and isopropanol (99+1) to dissolve 1kg of raw material stevioside (glycoside mixture); place crystallization at -18°C for 24h, then transfer to 4°C for 48h; filter to obtain crystals of about 0.5 kg; recrystallize once under the above conditions, and obtain about 0.25kg of recrystallized crystals; dissolve the crystals with 20L of pure water, separate and concentrate with a membrane with a molecular weight cut-off of 500; dry at 0.08MPa vacuum below 70°C for 24h to obtain high-purity Reiba Di A glucoside product is about 0.2kg.

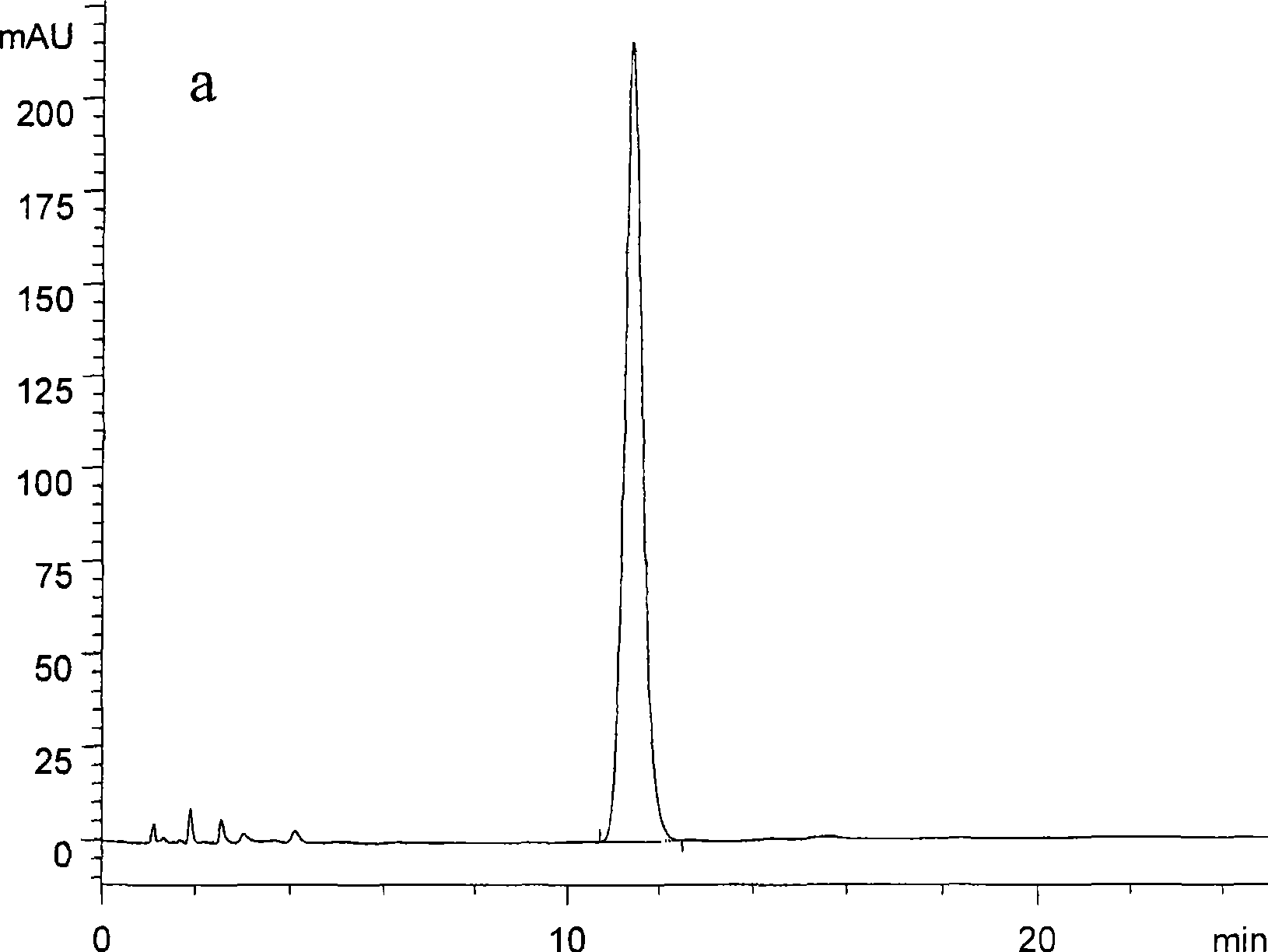

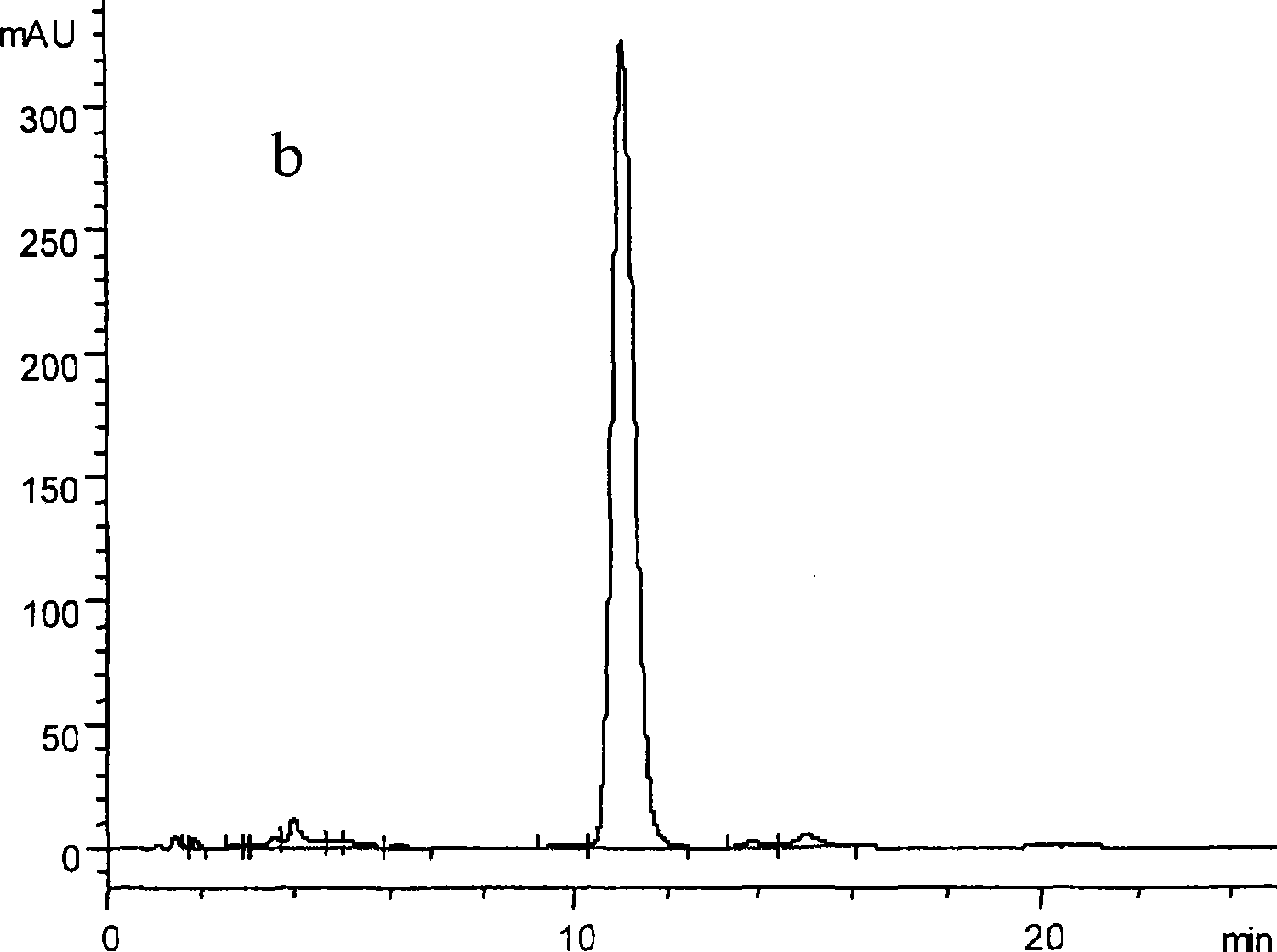

[0014] The liquid chromatograms of the rebaudioside A standard product (a) and the process product (b) are shown in Figure 1.

[0015] High performance liquid chromatography conditions:

[0016] Agilent100 high performance liquid chromatography; 210nm ultraviolet detector;

[0017] Chromatographic column: Zorbaxsb C18 column (4.6×150mm); column temperature: 30°C;

[0018] Mobile phase: acetonitrile-water...

Embodiment 2

[0021] Take 6L of mixed solution of methanol and isopropanol (99+1) to dissolve 1kg of raw material stevioside (glycoside mixture); place crystallization at -18°C for 48h, then transfer to 4°C for 24h; filter to obtain crystals of about 0.5 kg; recrystallize once under the above conditions to obtain about 0.25kg of recrystallized crystals; dissolve the crystals with 15L of pure water, separate and concentrate with a membrane with a molecular weight cut-off of 500; dry at 0.08MPa vacuum below 70°C for 16h to obtain high-purity Reiba Di A glycoside product 0.2kg.

Embodiment 3

[0023] Take 8L of mixed solution of methanol and isopropanol (99+1) to dissolve 1kg of raw material stevioside (glycoside mixture); place crystallization at -18°C for 48h, then transfer to 4°C for 48h; filter to obtain crystals of about 0.5 kg; recrystallize once under the above conditions to obtain about 0.25kg of recrystallized crystals; dissolve the crystals in 10L of pure water, separate and concentrate with a membrane with a molecular weight cut-off of 500; dry at 0.08MPa under vacuum for 12h at 70°C to obtain high-purity Reiba Di A glucoside product is about 0.2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com