Strip linear large power microwave switch and producing method thereof

A technology of microwave switches and manufacturing methods, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of limited device power, high welding process requirements, and large insertion loss, so as to reduce the accumulation of structural processing errors and improve The effect of carrying high power and reducing insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

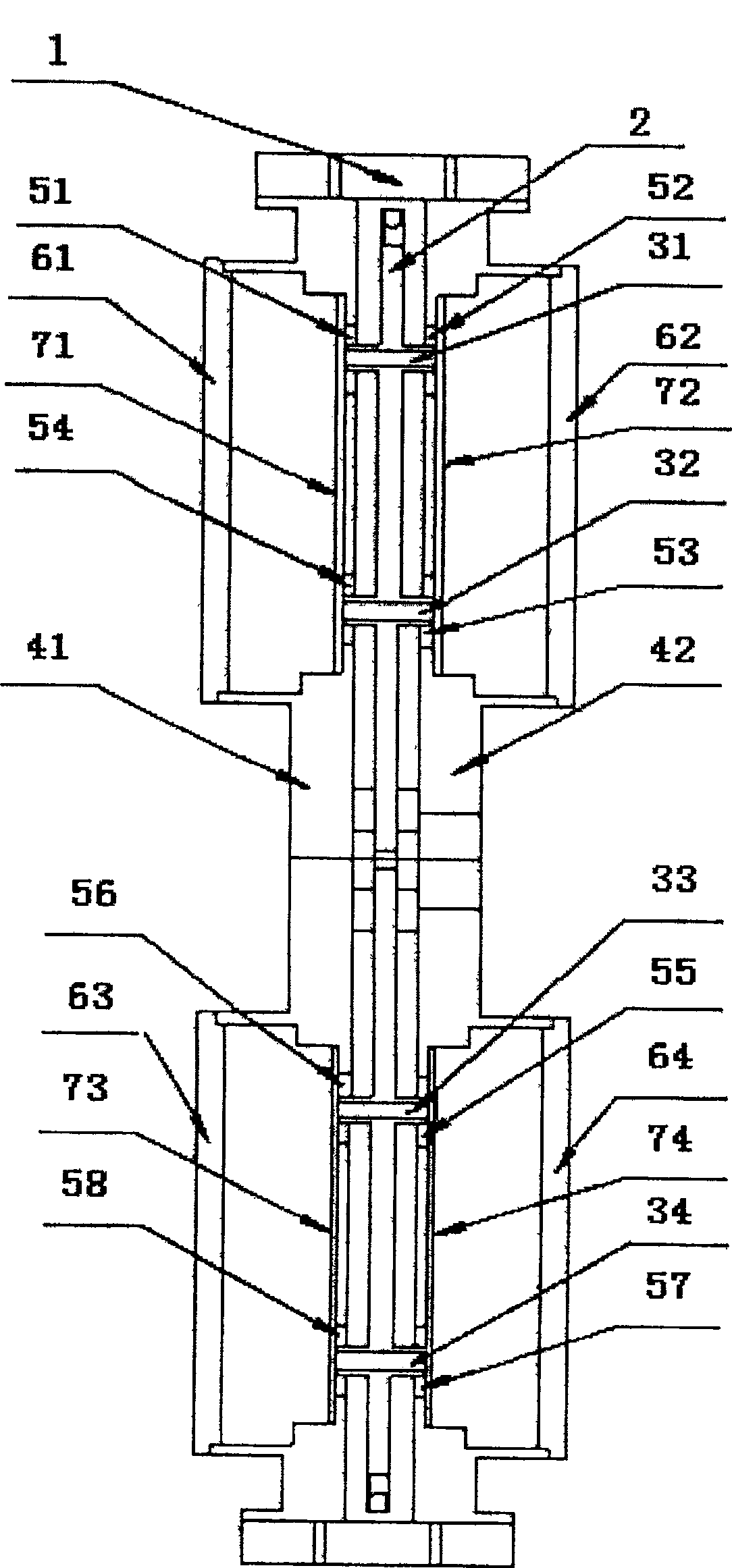

[0037] In order to further illustrate the features and structures of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

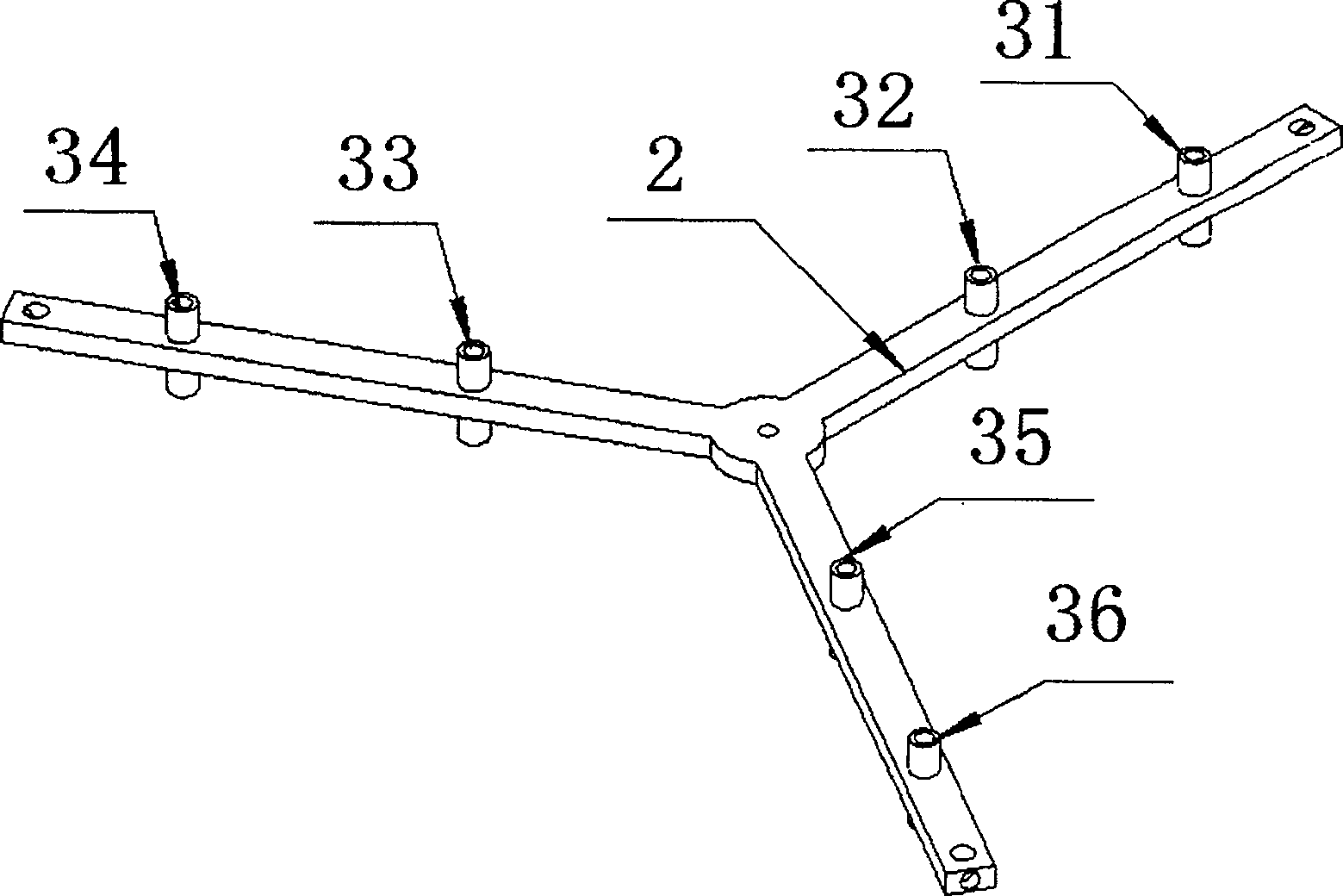

[0038] The present invention adopts the strip line as the microwave transmission carrier, air (vacuum) or dielectric material as the transmission medium, one or several stages of back-to-back uprights are arranged on the inner conductor core wire, and the uprights are then press-fitted on the upper cover plate and the lower cover plate The microstrip line connection on the microstrip line controls the surface-mounted microwave PIN diode on the microstrip line and the column to form a short-circuit surface or an open surface to realize the closing and opening of the microwave signal. The specific examples are as follows:

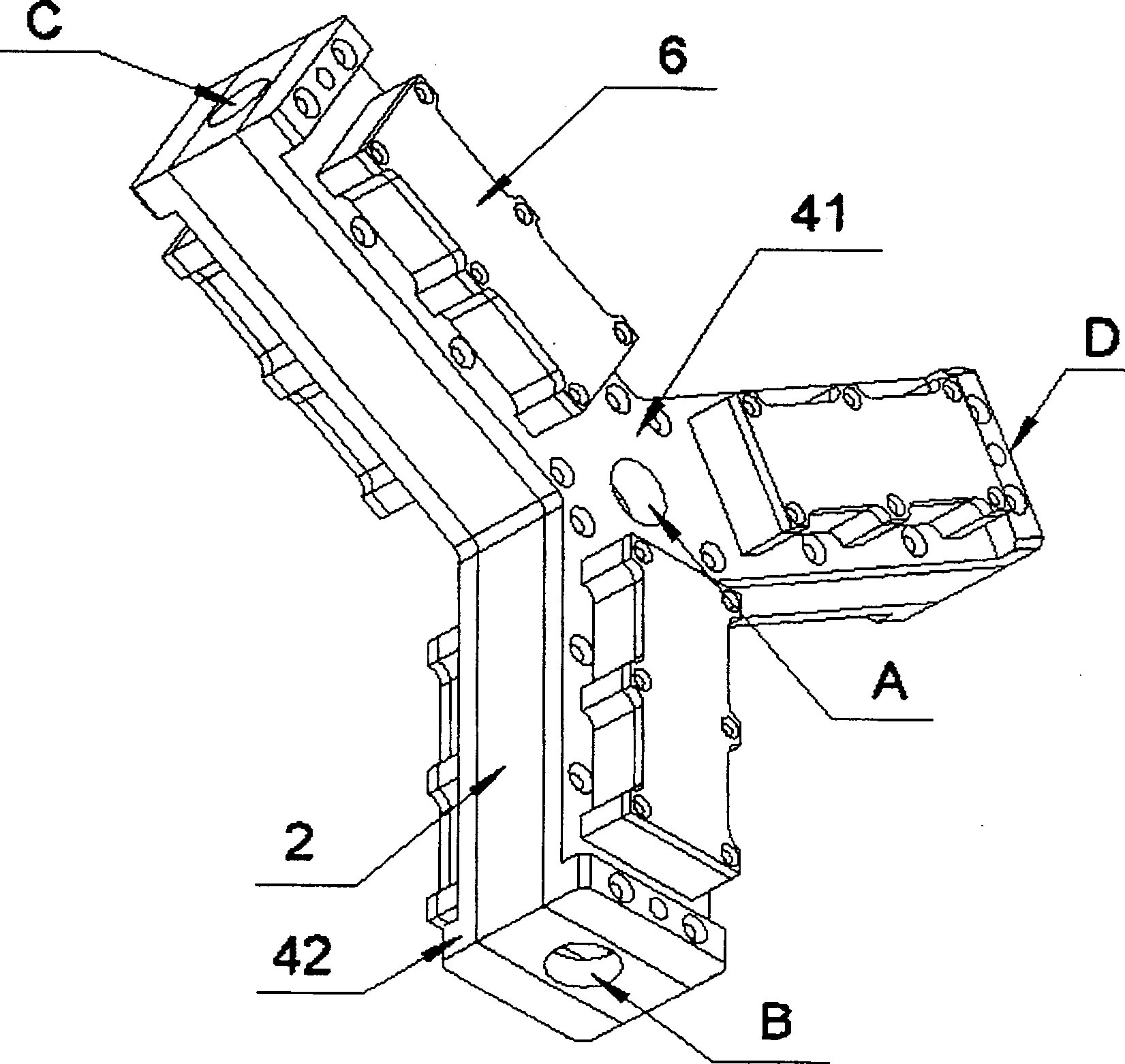

[0039] as in the present invention figure 1 , a schematic diagram of the outline structure of a stripline single-pole three-throw high-power microwave switch, marki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com