Plasma etching method

A plasma and etching technology, applied in the field of shallow trench isolation, can solve the problems of increased leakage current and increased power consumption, and achieve the effect of suppressing leakage current and saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

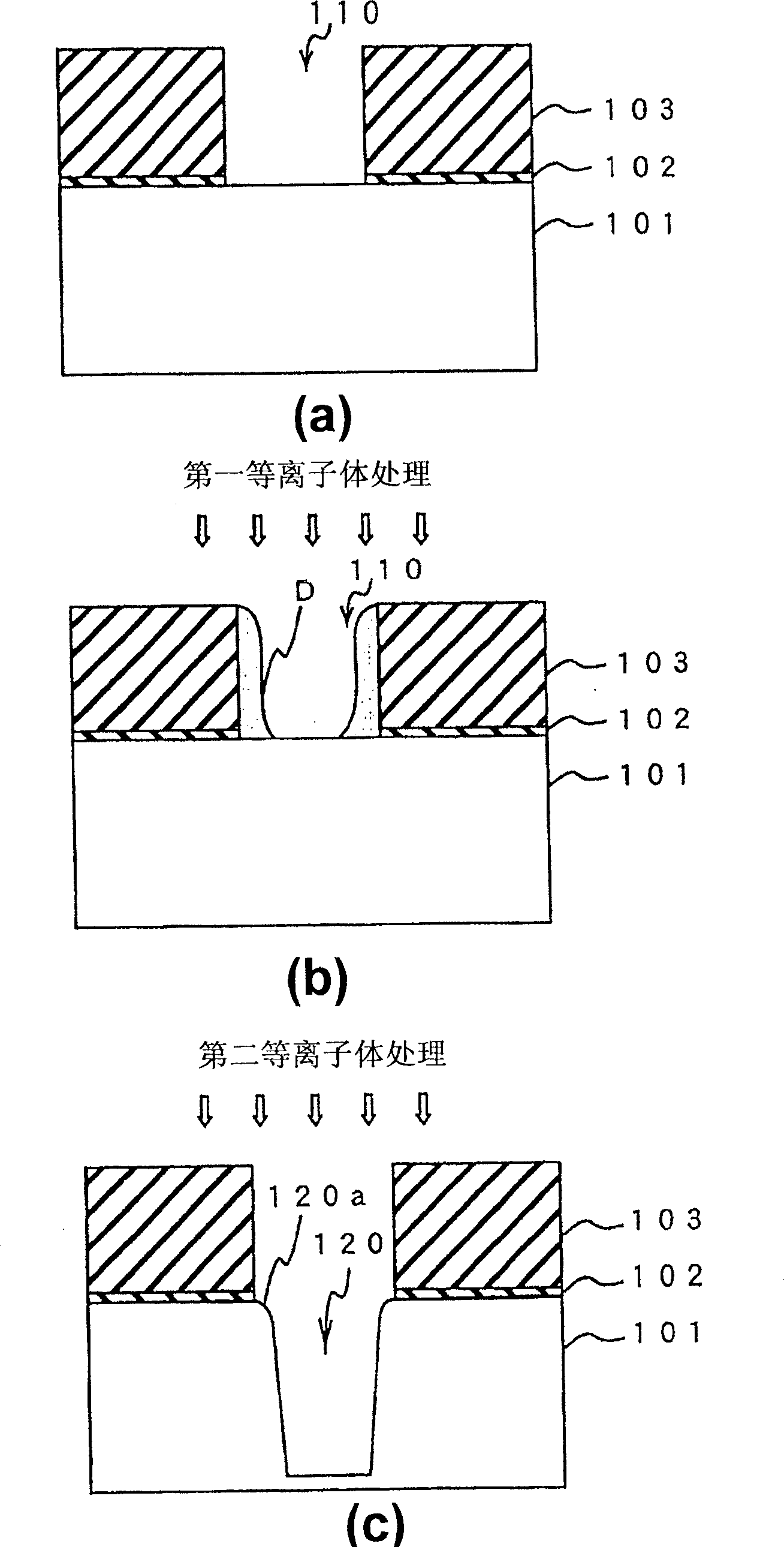

[0045] figure 1 It is a schematic diagram showing a main part of a longitudinal section of a semiconductor wafer (hereinafter simply referred to as "wafer") W in a silicon trench etching process such as enlarged STI for explaining one embodiment of the present invention. like figure 1 As shown in (a), on the silicon substrate 101 constituting the wafer W, for example SiO 2 etc. silicon oxide film 102, and on it, for example, form Si 3 N 4 and so on silicon nitride film 103 . The silicon nitride film 103 functions as a hard mask.

[0046] The silicon nitride film 103 and the silicon oxide film 102 are patterned into a predetermined shape to form a mask layer. figure 1 In (a), the groove part 110 which is the opening which comprises a pattern is shown in figure. In addition, the patterning of the silicon nitride film 103 and the silicon oxide film 102 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com