Distributing structure, it mfg. method and optical equipment

A technology for wiring structure and optical equipment, applied in semiconductor/solid-state device manufacturing, light source, electric light source, etc., can solve problems such as increased contact resistance and poor adhesion, and achieves prevention of diffusion, reduction of migration, reduction of The effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

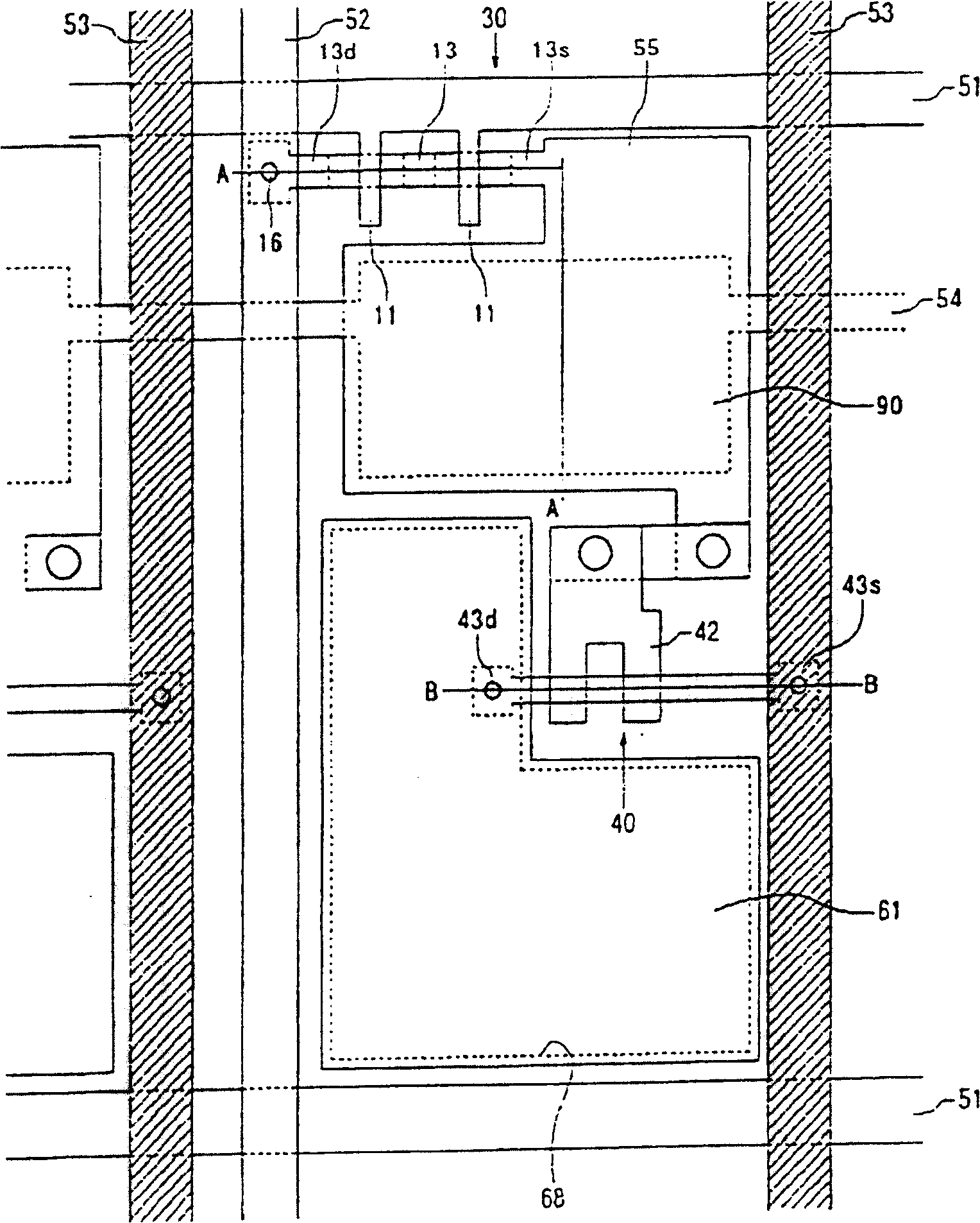

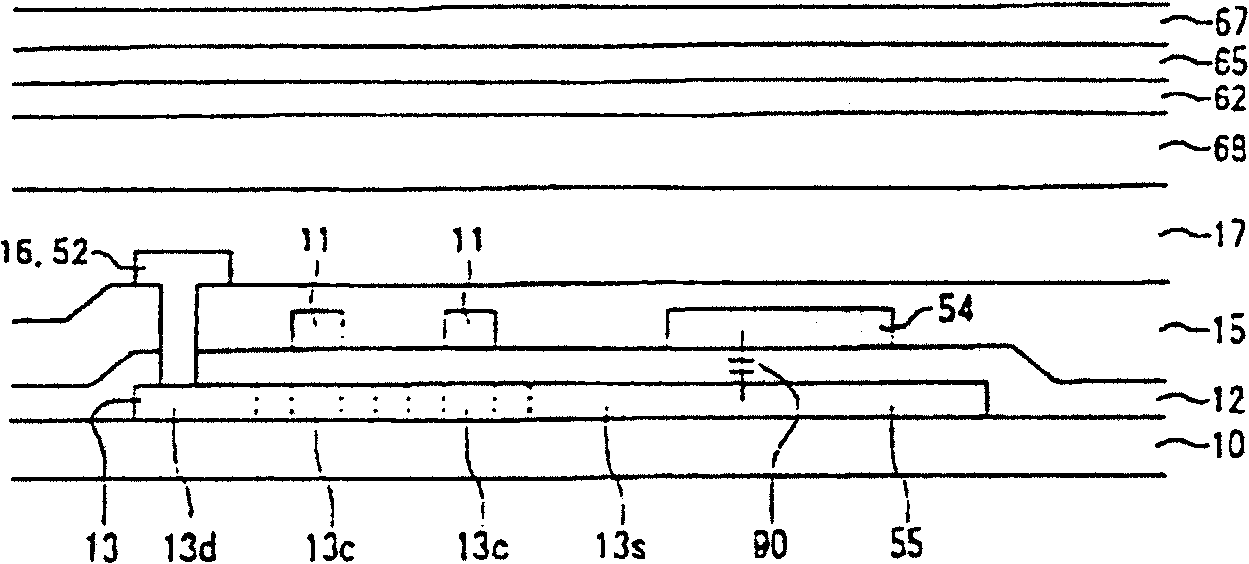

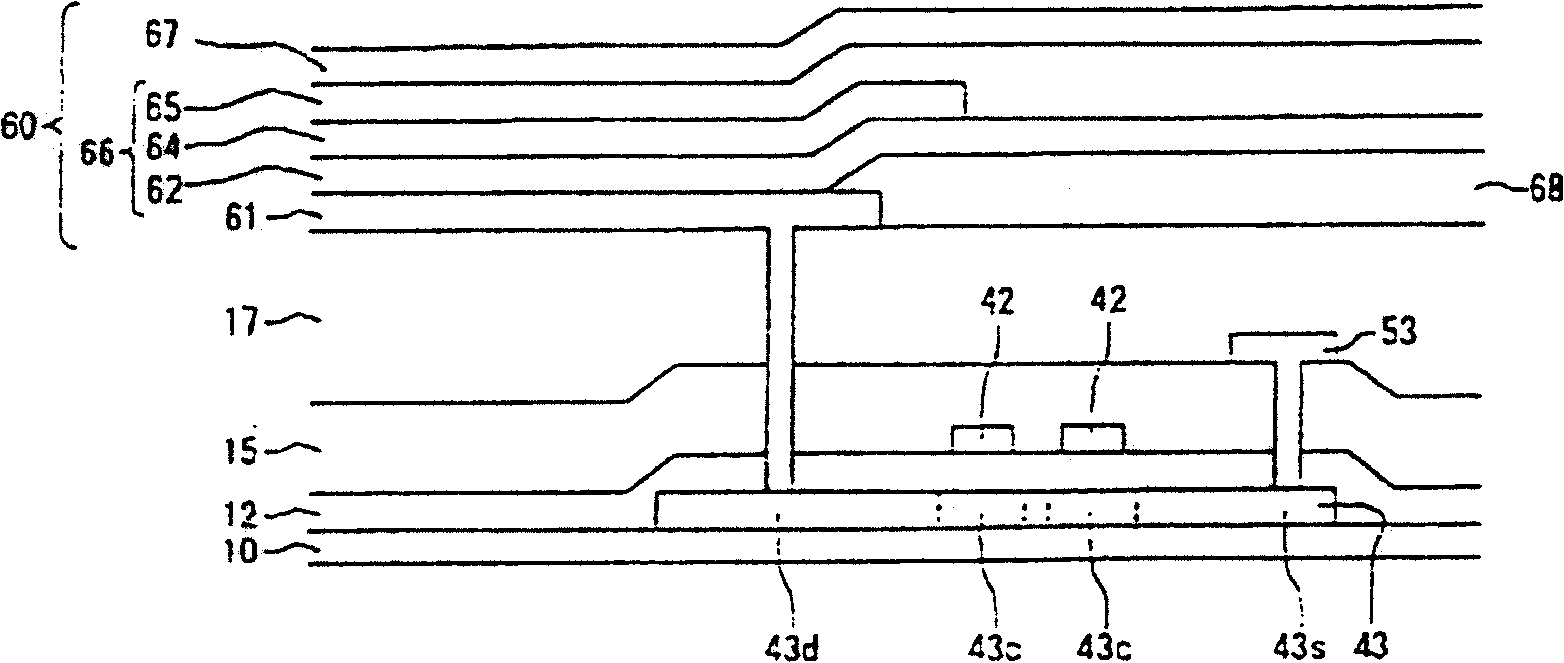

[0081] The present invention will be explained with reference to specific examples.

[0082] In the formation of SiO 2 After the film is used as an interlayer insulating film to become a base, a contact hole is formed in the interlayer insulating film. Then, the layered wiring structure is deposited on the interlayer insulating film using a load-lock (LL) type multi-chamber deposition apparatus. The deposition apparatus contains a LL chamber, a process chamber, a first sputtering chamber for placing molybdenum targets, and a second sputtering chamber for placing aluminum-neodymium alloy targets. The neodymium content in the aluminum-neodymium alloy is 2 atomic percent.

[0083] First, the LL chamber, the process chamber, the first deposition chamber and the second deposition chamber were pre-evacuated to 10 -3 Pa, the substrate is then transported from the LL chamber to the processing chamber. The gate valve between the processing chamber and the first sputtering chamber i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com