Transverse pipe type heat transfer reaction unit

A technology of tubular heat exchange and reaction equipment, which is applied in the direction of heat exchange equipment safety devices, heat exchange equipment, lighting and heating equipment, etc., and can solve the problem of uneven distribution of reaction gas in radial flow, affecting reaction efficiency, upper and lower parts The density is difficult to be consistent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

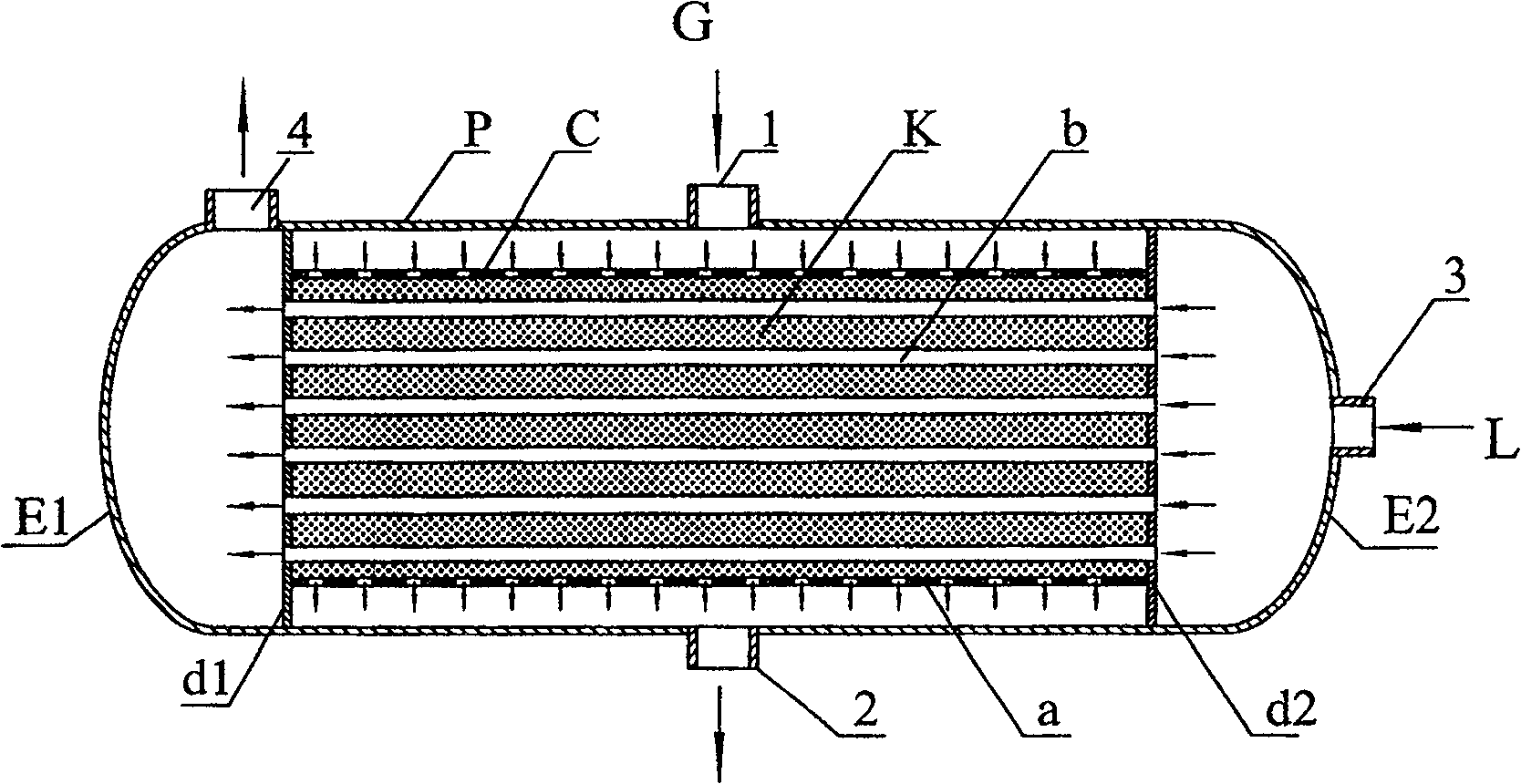

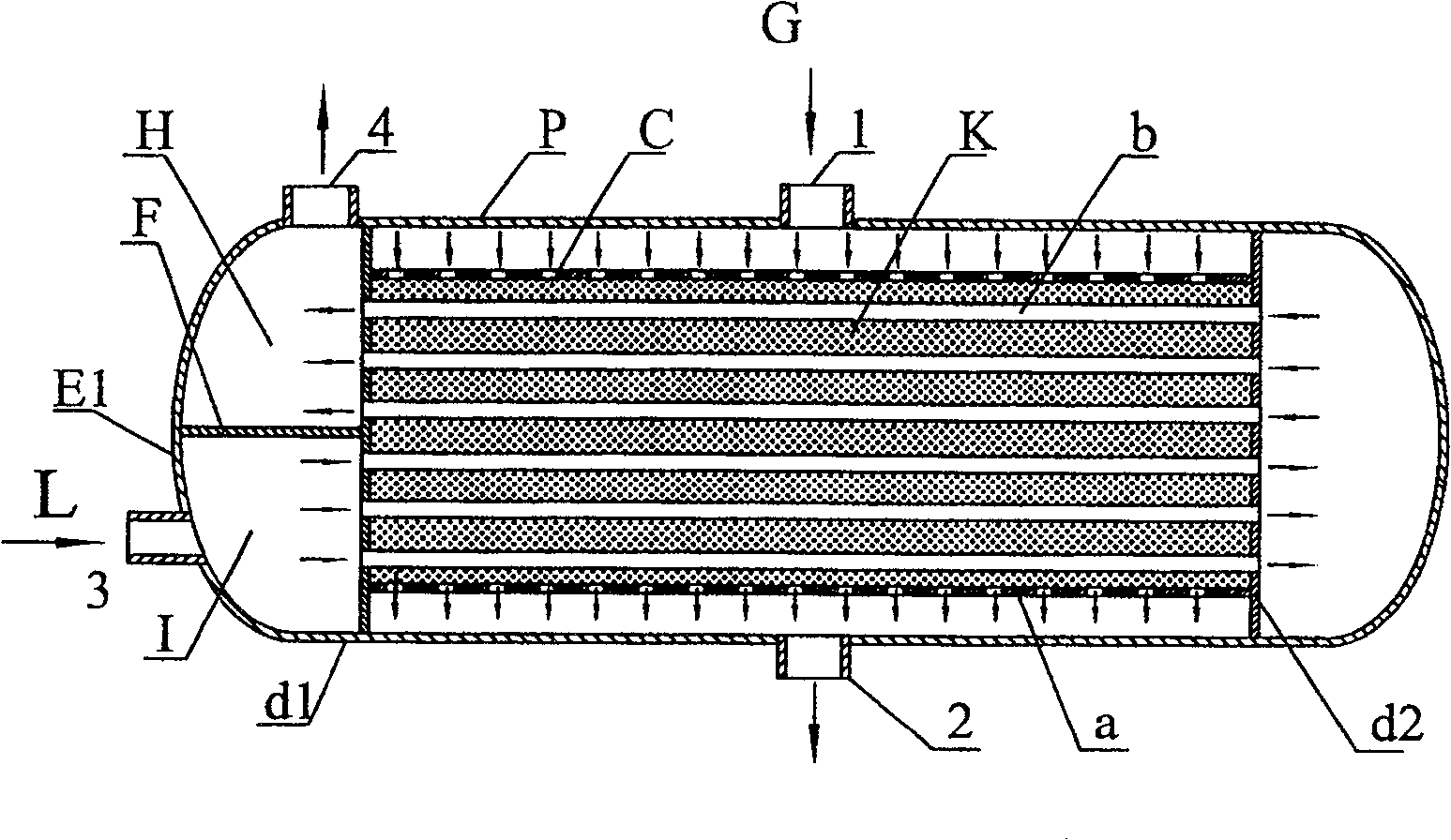

[0049] use Figure 6 A horizontal U-shaped tube synthesis tower for low-pressure methanol synthesis, with an inner diameter of 6.5 meters and a length of 16 meters, filled with NC307 or C302 copper-based methanol, and a catalyst loading capacity of 390m 3 , the synthetic pressure is 8.9MPa, the composition of the gas entering the tower: H 2 63.73%, CO 10.25%, CO 2 5.87%, H 2 O 0.06%, N 2 7.81%, CH 4 12.02%, CH 3 OH 0.28%, the amount of gas entering the tower is 3600000Nm 3 / h, the hot spot temperature of the catalyst layer is 260°C, the output of methanol is 10,000 tons / day, and the by-product steam of 3.8MPa in the heat exchange tube b is heated by reaction heat to 10,000 tons / day. However, under the same conditions and output, the Lurgi shell-and-tube tower needs more than 6 synthesis towers with a diameter of 4 meters, and the investment is more than doubled.

[0050] The subject matter of the present invention has been fully described above through numerous illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com